750-96 (revised 2010)

Model CB Packaged Boiler Manual

7-13

7.14 — Fuel Oil Metering Valve, Adjusting and Relief Valves

4. Loosen the setscrews in the cam hub and rotate or move the cam to a position where it does not interfere with

the stem removal.

5. withdraw the metering valve stem and spring. Do not drop or mishandle. Check for nicks or scratches. Check

that the pin holding the metering portion is not protruding. Back off the packing gland.

6. Remove the capscrews holding the jackshaft support bracket so that the bracket can be moved. It may be nec-

essary to also loosen the supporting bracket on the far end of the shaft.

7. Remove the existing packing and guides. Do not reuse these.

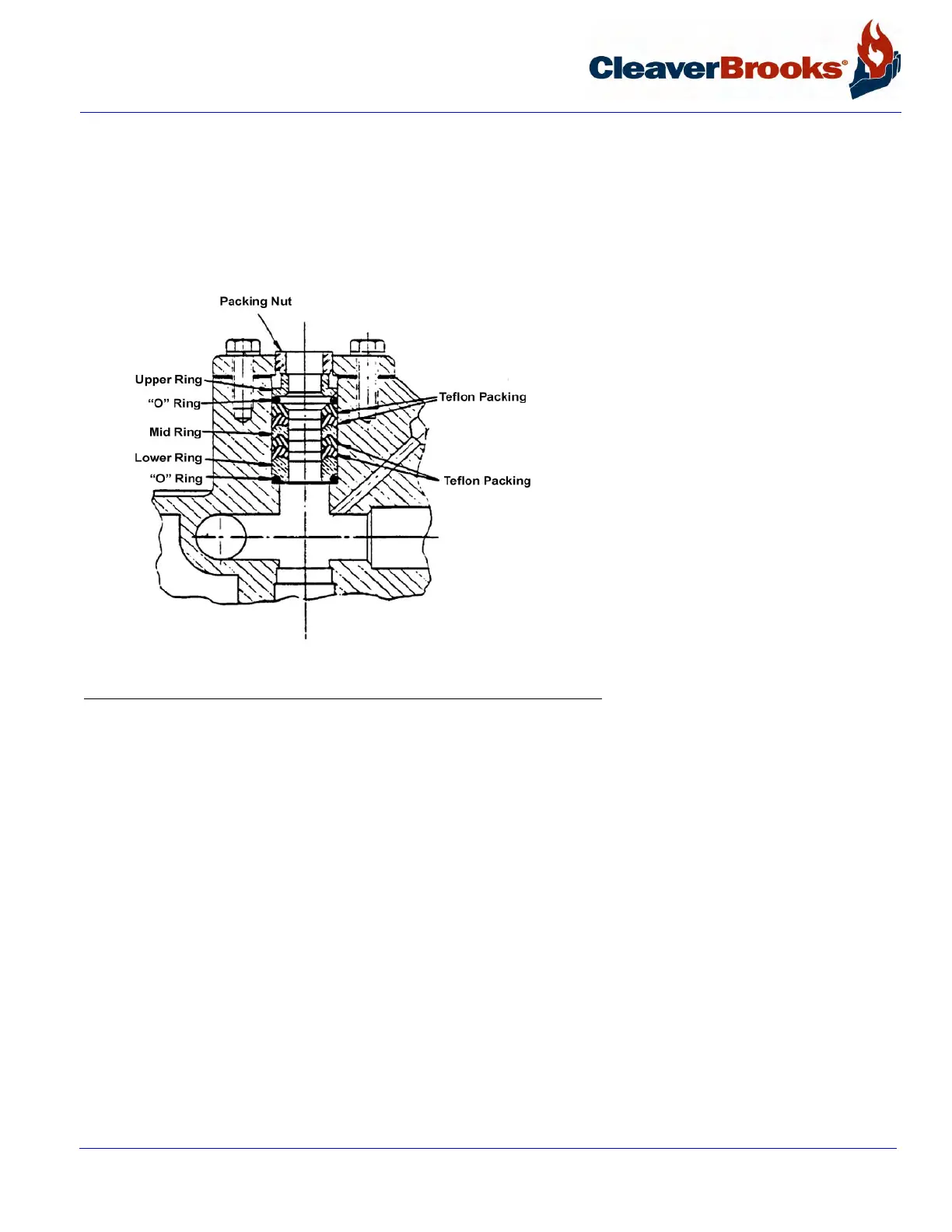

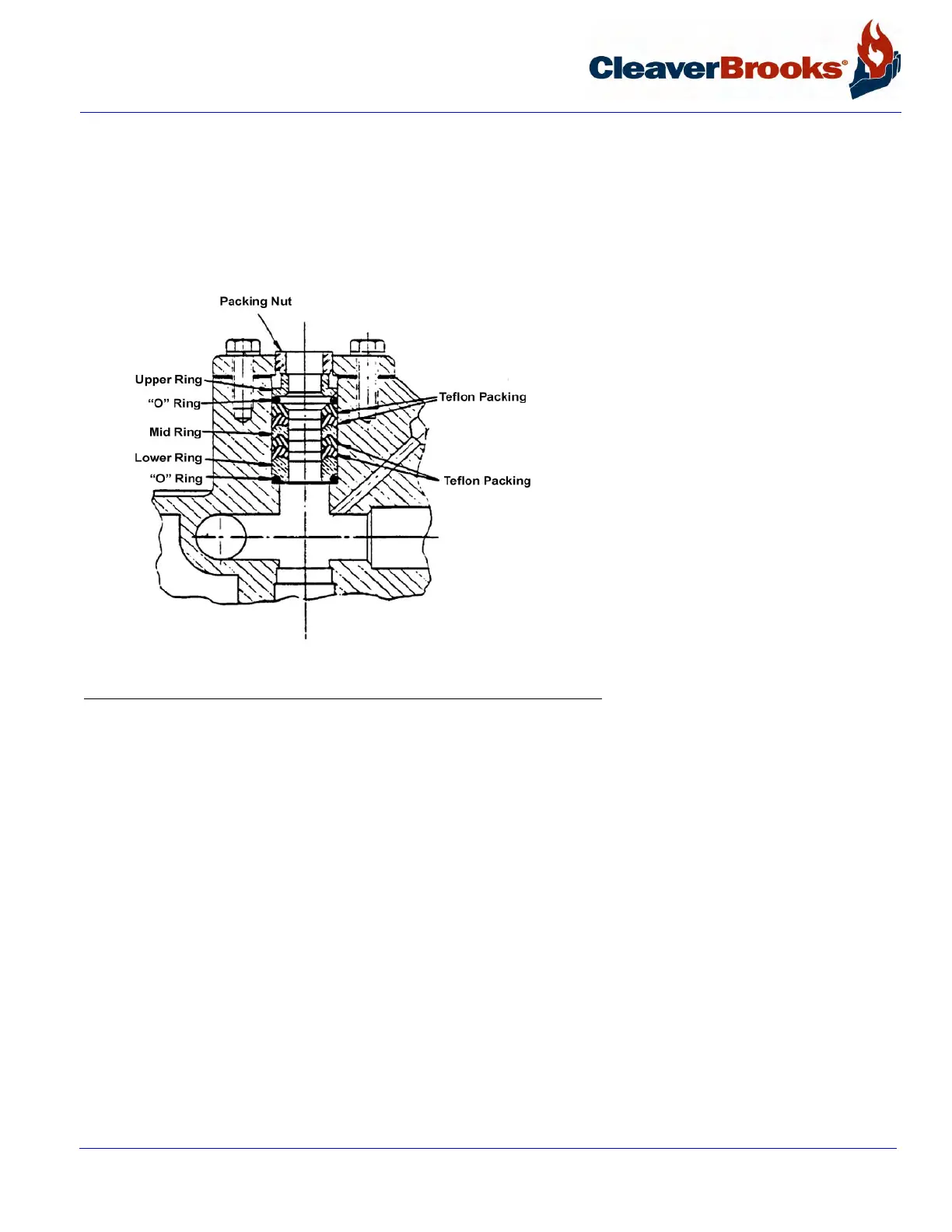

8.Lightly coat the stem with the lubricant pro-

vided with the packing kit. Place the new pack-

ing, o-rings, and guides onto the stem in the

sequence shown in Figure 7-5. The beveled face

of the guides and the Teflon rings must face

upward, with the exception of the upper brass

guide which is faced down. Make sure that the

o-rings are properly located.

9.Using the stem as a guide, insert the assem-

bled packing into the cavity, then withdraw the

stem.

10.Replace the gasket, put the support in place,

and secure all fastenings. Install the packing

gland.

FIGURE 7-5. Metering Valve Packing Sequence

11. Replace the metering stem and spring. Lightly lubricate the stem to facilitate insertion and easy movement.

Use care when inserting so that the orifice and the stem are not damaged.

12. Snug the packing gland, but only sufficiently to place slight tension on the packing. The stem must move freely

from the force of the spring.

13. Work the stem up and down several times to insure that it is free-moving.

14. Depress the valve stem and replace the cam. Mate the match marks and secure the setscrews. Make sure the

cam spring is centered in the roller.

15. Restore the oil flow. Test fire the burner at various firing rates making certain that the metering stem freely fol-

lows the cam.

16. Tighten the packing gland after a period of operation, if necessary, to maintain proper tension on the packing.

Do not over tighten.

If there are indications that the oil metering valve has become clogged at its orifice, it will be necessary to disas-

semble the control to remove the obstruction. Clean the slotted stem of the oil metering valve with suitable solvent

and blow dry with an air line. Follow the above procedure when removing or reinstalling the metering valve stem.

Also check all fuel line strainers.

Loading...

Loading...