The Pressure Vessel

2-8

750-96 (revised 2010)

Model CB Packaged Boiler Manual

If any unwanted conditions are observed, your water consultant or water treating company should be contacted

for recommendations.

Any sludge, mud, or sediment found will have to be flushed out. The effectiveness of the blowdown practiced on

steam boilers will be verified and scheduling or frequency of blowdown may have to be revised. The need for peri-

odic draining or washout will also be indicated.

Any oil or grease present on the heating surfaces should be removed promptly by a boil-out with an alkaline deter-

gent solution.

2.6 — Boil-Out of a New Unit

The internal surfaces of a newly installed boiler may have oil, grease, or other protective coatings used in manu-

facturing. Such coatings must be removed since they lower the heat transfer rate and could cause overheating of

a tube. Before boiling out procedures may begin, the burner should be ready for firing. The operator must be

familiar with the procedure outlined under burner operation.

Your water consultant or water treatment company will be able to recommend a cleaning or boil-out procedure. In

the event such service is unavailable or is yet unscheduled, the following information may be of assistance.

There are several chemical suitable for this purpose. Soda ash (sodium carbonate) and caustic soda (sodium

hydroxide) at the rate of 3 to 5 pounds each per 1,000 pounds of water, along with a small amount of laundry

detergent added as a wetting agent is one combination often used.

Cleaver-Brooks markets a prepared alkaline-phosphate blend under the trade name of “Poly-Clean.” This is avail-

able in various container sizes from your Cleaver-Brooks Service and Parts Representative. Follow the provided

instructions for its use.

The suggested general procedure for cleaning a boiler is:

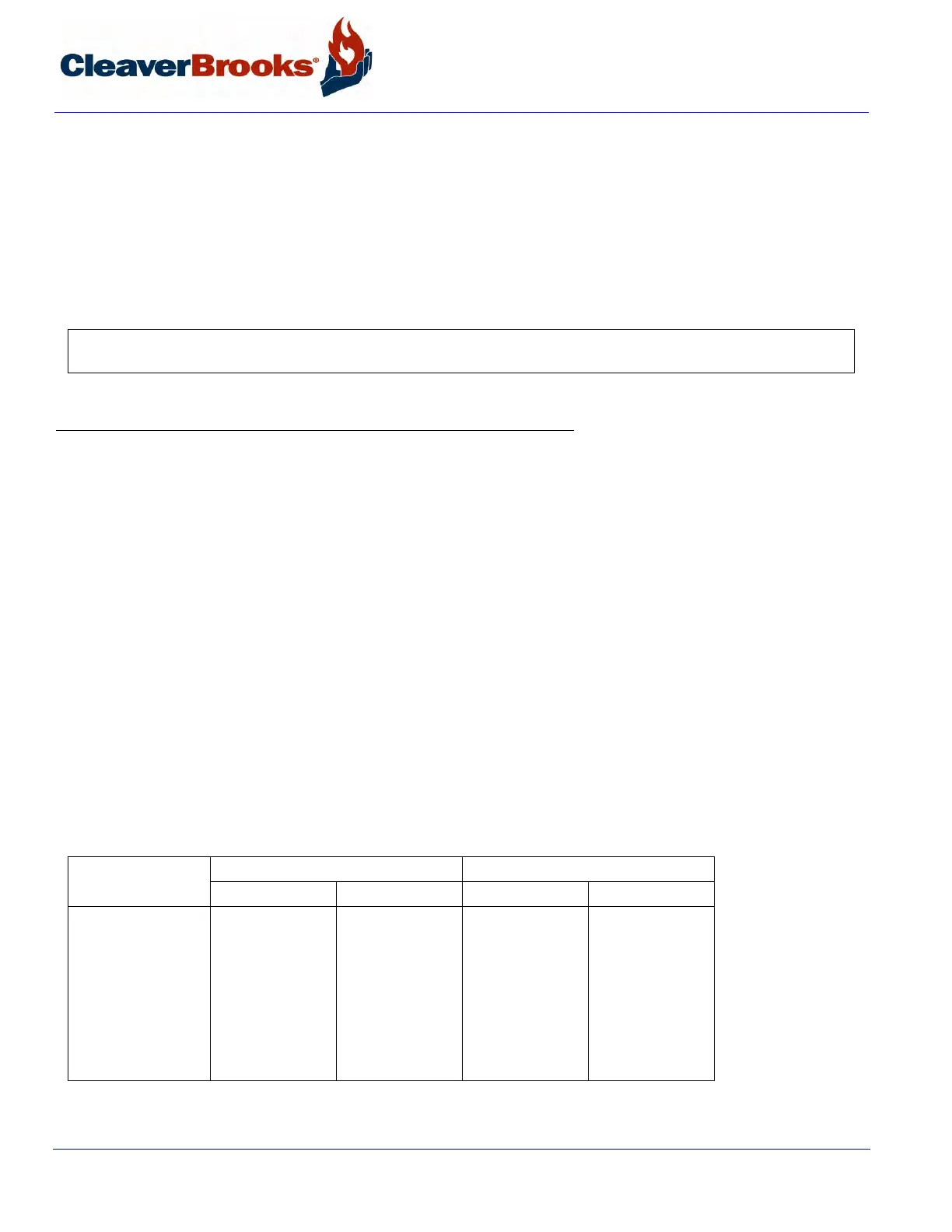

1. Refer to the chart below to determine water capacity and have sufficient cleaning material on hand.

NOTE: Temperature of initial fill of water for hydrostatic tests, boilout, or for normal operation should be as stated in

the ASME Boiler Code.

Boiler Model and

Size

Water - Gallons Water - Weight

Normal Flooded Normal Flooded

CB50

CB60

CB70

CB80

CB100

CB100A

CB1025A

375

350

550

535

610

-

-

440

420

650

630

715

595

670

3125

2920

4625

4460

5085

-

-

3665

3500

5420

5250

5960

4960

5585

Loading...

Loading...