750-96 (revised 2010)

Model CB Packaged Boiler Manual

7-15

7.15 — Air Pump and Lubricating System

2. The oil and its container should be clean. although there is a strainer in the lube oil line, its purpose is to remove

any unwanted materials rather than to act as a filter for unclean oil.

7.15.3 — Lubricating Oil Strainer and Cooling Coil

Air pressure from the pump forces lubricating oil from the tank through a cooling coil to the pump. The oil lubri-

cates the pump bearings and also provides a seal and lubrication for the pump vanes.

The cooled oil flows to the pump through the strainer in the filler pipe. It is possible to visually verify oil flow during

operation by removing the filler cap and checking the flow. If necessary, the strainer may be cleaned during opera-

tion.

In the event that it is necessary to clean the strainer during operation, clean it and replace immediately. It can be

cleaned by immersing it in solvent and blowing it dry with compressed air. Do not operate without the strainer any

longer than necessary and never add new oil unless it is in place. A spare strainer basket can be obtained, if

desired, and used on a rotating basis while the other is serviced.

There is an orifice fitting installed at the junction of the tubing and the filler pipe. This orifice restricts the flow of

lubricating oil to the pump. It must be installed in the event of dismantling during pump replacement or other repair

work.

7.15.4 — Air Cleaner

Never operate the air pump without the air cleaner (filter) in place. The cleaner itself must be periodically checked

and its element flushed and cleaned. The correct level of oil must be maintained in the cleaner.

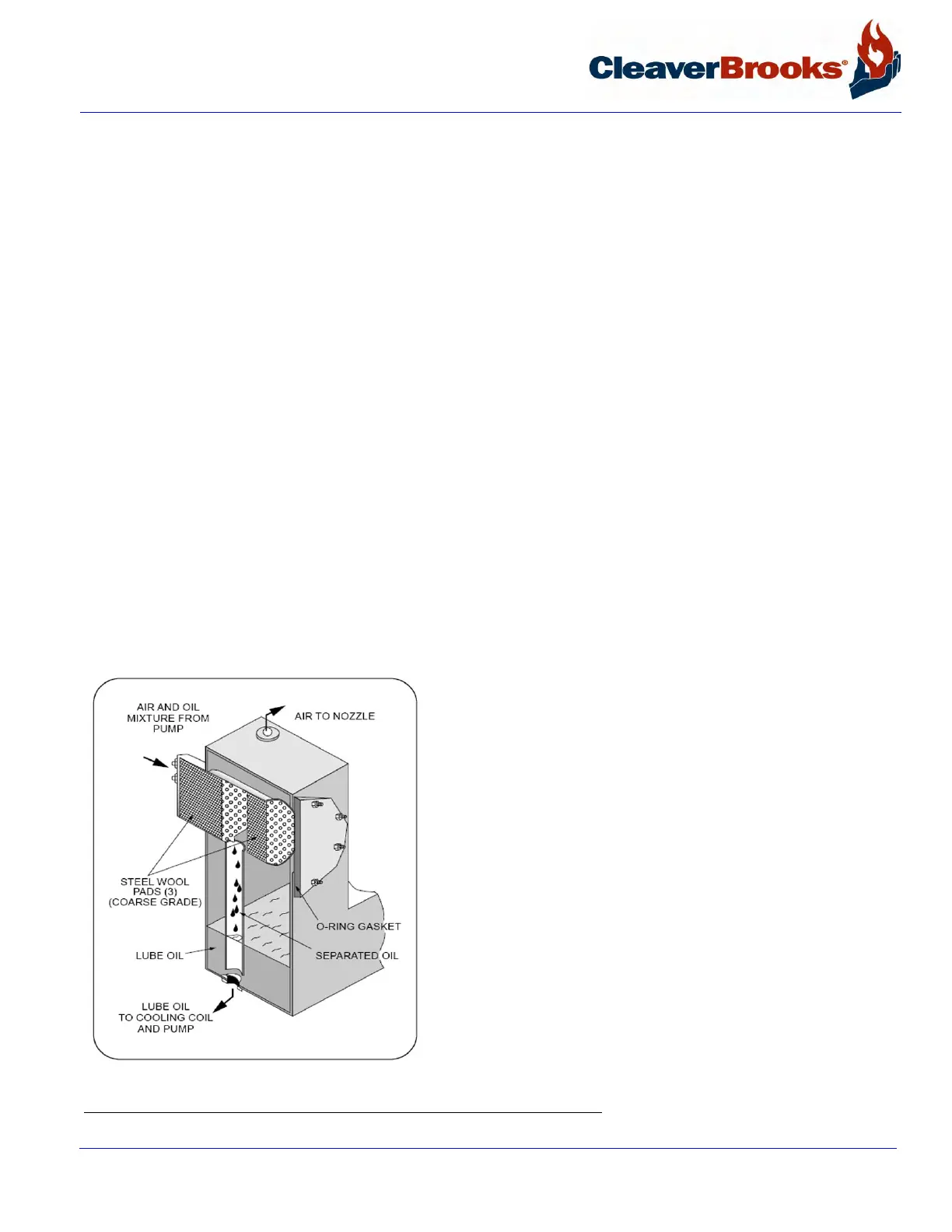

7.15.5 — Air-Oil Tank

Pads of steel wool are used in this tank as a filtering medium to

separate the lube oil from the compressed air.

These pads play a very important role and should be replaced

periodically. It is also important that a proper grade of steel wool

be used. No. 3 coarse grade American steel wool or an equiva-

lent (CB919-124) is recommended. Do not substitute other

grades. Three pads are required. When replacing the steel wool,

insert two pads into the cylinder. Alternate the grain of the pads.

Install the spacer with its stub end toward the opening and fit one

pad over the stub. Be careful not to overly compress the steel

wool and be sure that it is fluffed out to fill all available space.

Improper packing can cause high oil consumption. After the last

pad is in place, slip the retainer screen onto the cylinder. Be sure

to fit the o-ring gasket under the cover so that a tight seal is

obtained.

FIGURE 7-7. Air-Oil Tank

Loading...

Loading...