750-96 (revised 2010)

Model CB Packaged Boiler Manual

5-11

5.7 — Gas Pressure and Flow Information

The reading must be steady. If the reading fluctuates, recheck the adjustment. Make sure that the flame detec-

tor is properly seated and that the lens is clean.

8. Return the test switch to the RUN position.

9. If main flame has not be previously established, proceed to do so in accordance with instructions provided else-

where in the manual.

10. The reading of the main flame signal should also be checked. Observe the flame signal for pilot alone, pilot and

main burner flame together, and the main burner flame at high, low, and intermediate firing rate position. Read-

ings should be steady and in the range indicated in step 7. If there are any deviations, refer to the troubleshoot-

ing section in the technical bulletin.

5.7 — Gas Pressure and Flow Information

Because of variable in both the properties of gas and the supply system, it will be necessary to regulate the pres-

sure of the gas to a level that produces a steady, dependable flame that yields highest combustion efficiency at

rated performance yet prevents overfiring. Once this optimum pressure has been established, it should be

recorded and periodic checks made to verify that the regulator is holding the pressure at this level. Occasional

modification in fuel composition or pressure by the supplier may, at times, require readjustment to return the

burner to peak efficiency. Since the gas pressure regulator itself is usually furnished by others, detailed adjust-

ment instructions and adjusting procedures recommended by the manufacturer should be followed.

5.7.1 — Pressure

The gas supplied must provide not only the quantity of gas demanded by the unit, but must also be at a pressure

high enough to overcome the pressure loss due to the frictional resistance imposed by the burner system and con-

trol valves.

The pressure required at the entrance to the burner train for rated boiler output is termed “net regulated pres-

sure.” The gas pressure regulator must be adjusted to achieve this pressure to assure full input.

The pressure requirement varies with boiler size, altitude, and type of gas train. Refer to Table 1 for pressure

requirements.

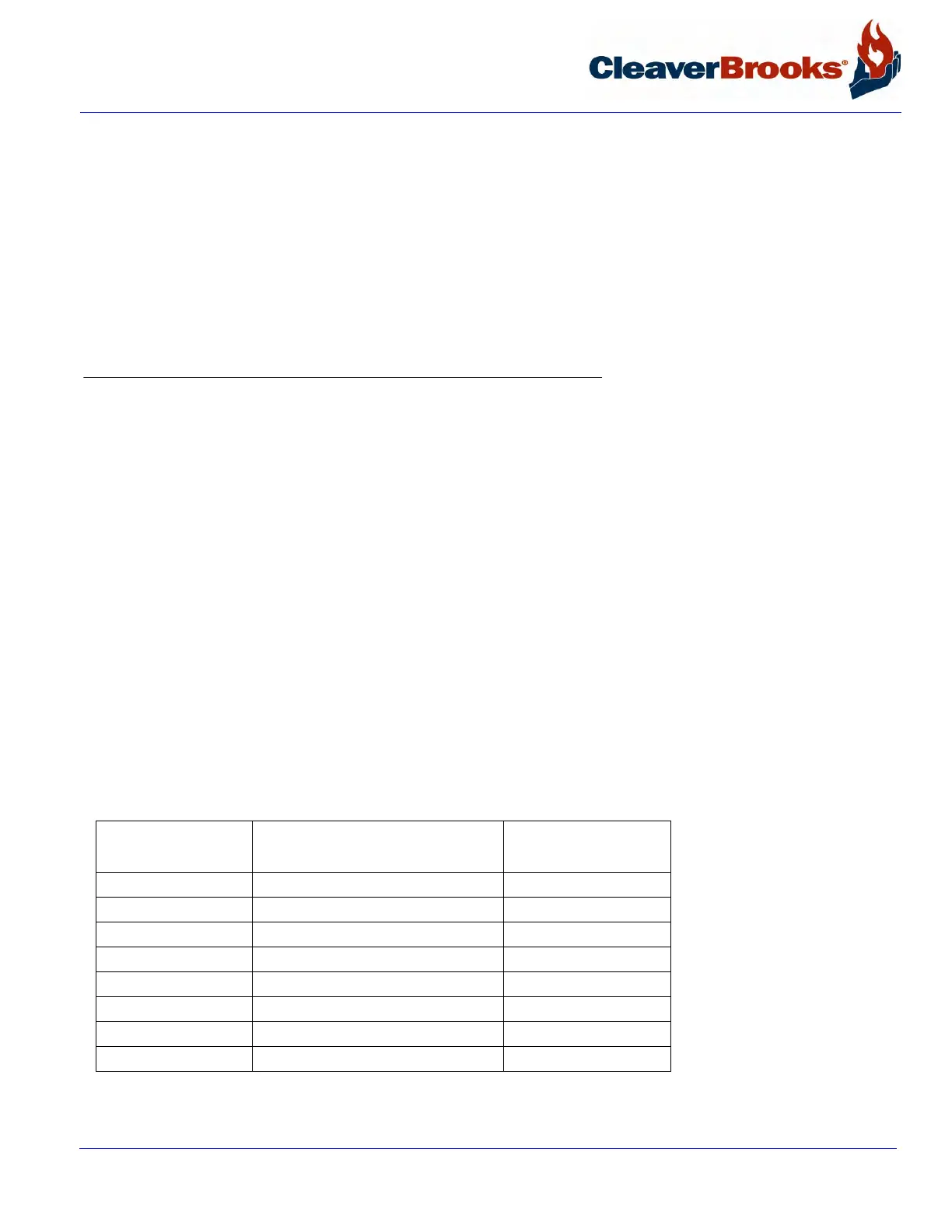

TABLE 1. Minimum Net Regulated Gas Pressure for Rated Boiler Output (Required at Gas Train Entrance)

Boiler Size (H.P.)

Standard and FM Approved

Train IRI Approved Train

50 4.5 5.5

60 5.5 6.5

70 8.0 9.5

80 9.5 11.0

100 8.5 10.5

100A 8.5 10.5

100S 9.0 11.5

125A 12.0 12.0

Loading...

Loading...