The Pressure Vessel

2-6

750-96 (revised 2010)

Model CB Packaged Boiler Manual

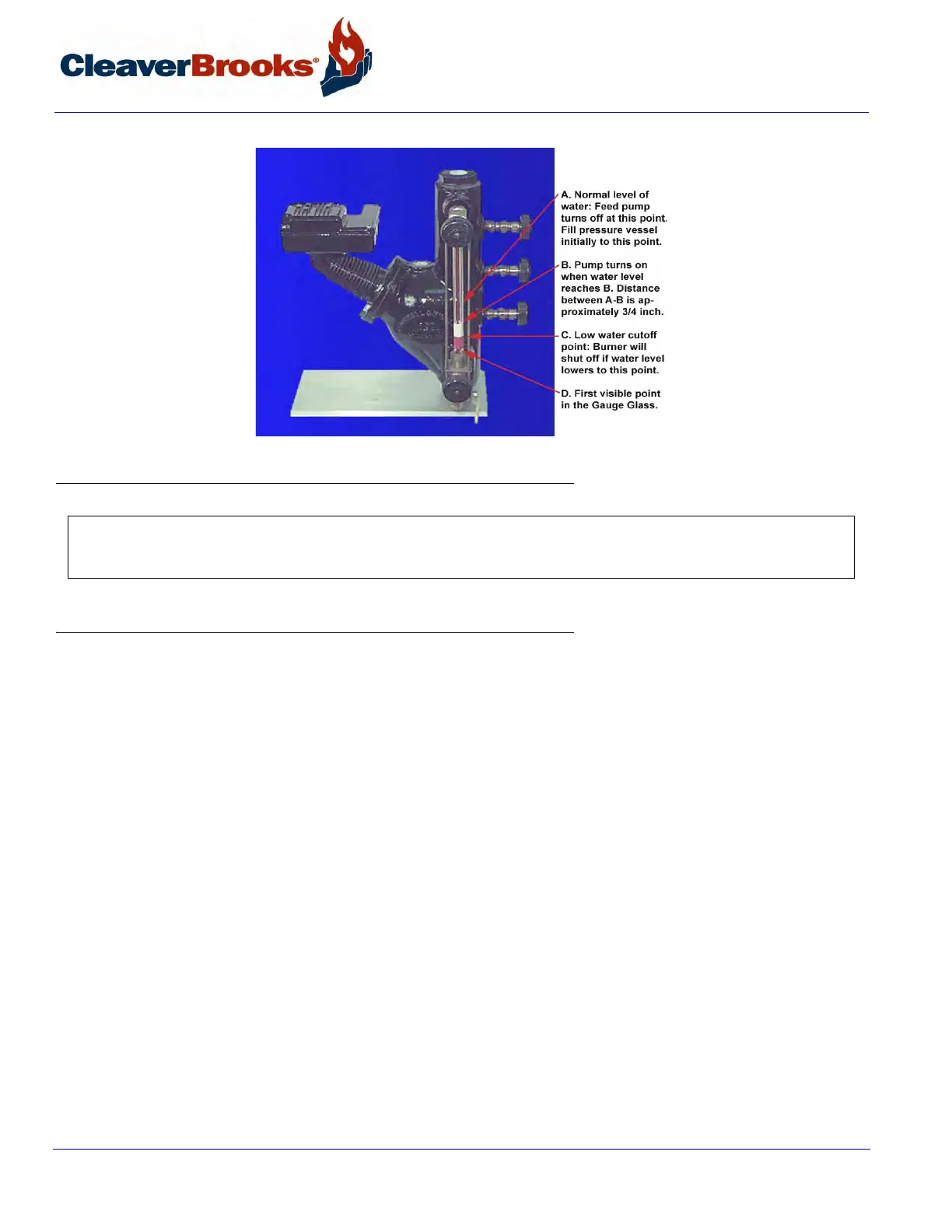

FIGURE 2-3. Boiler Water Level Details (Steam Boiler)

2.4 — Water Treatment

Maximum effectiveness and long trouble-free life of pressure vessels, at the lowest cost consistent with good engi-

neering and operating practice, are functions of properly treated boiler feedwater. The recommendations of a

water consultant or a reliable water treating company should be followed rigidly to prevent the presence of

unwanted solids and corrosive gases. Objectives of water treatment in general are:

• Prevention of hard scale deposits or soft sludge deposits which impair the rate of heat transfer and can lead to

overheated metal and costly downtime and repairs.

• Elimination of corrosive gases in the supply or boiler water.

• Prevention of intercrystalline cracking or caustic embrittlement of boiler metal.

• Prevention of carryover and foaming.

To accomplish these objectives, proper feedwater treatment before and after introduction of the water into the

boiler is required. The selection of pre-treatment processes depends upon the water source, its chemical charac-

teristics, amount of makeup water needed, plant operating practices, etc. These treating methods include filter-

ing, softening, de-mineralizing, deaerating, and preheating. After-treatment involves chemical treatment of the

boiler water.

Because of the variables involved, no one “boiler compound” can be considered a “cure-all” nor is it advisable to

experiment with homemade treating methods. Sound recommendations and their employment should be aug-

mented by a periodic analysis of the feedwater, boiler water, and condensate.

The internal or waterside surfaces of the pressure vessel should be inspected with sufficient frequency to deter-

mine the presence of any contamination, accumulations of foreign matter, of corrosion and/or pitting. If these con-

NOTE: In the event that water column isolation valves are provided or installed, it must be established that these

valves are not only open but that they are sealed or locked in the open position. If these valves are installed, it is illegal

to operate the boiler with closed or unsealed open valves.

Loading...

Loading...