750-96 (revised 2010)

Model CB Packaged Boiler Manual

5-5

5.5 — Burner Operating Controls: General

5.5 — Burner Operating Controls: General

In general, when adjusting controls check to see that they are level, especially those containing mercury switches.

On temperature sensing controls, make sure that the bulb is properly bottomed in its well and that connecting tub-

ing is not kinked.

Controls are carefully calibrated during their manufacture and do not normally require re-calibration. The dial set-

tings are generally quite accurate although it is not unusual to have a slight variation between a scale setting and

an actual pressure gauge or thermometer reading and to readjust the control setting to agree with these readings.

This is based, however, on pressure gauges and thermometer being accurate.

Burner controls properly set to match load demands will provide operational advantages and achieve the following

desirable objectives:

• The burner will be operating in low fire position prior to shut down.

• The burner will operate at low fire for a brief period on each start during normal operation.

• Eliminate frequent burner on-off cycling.

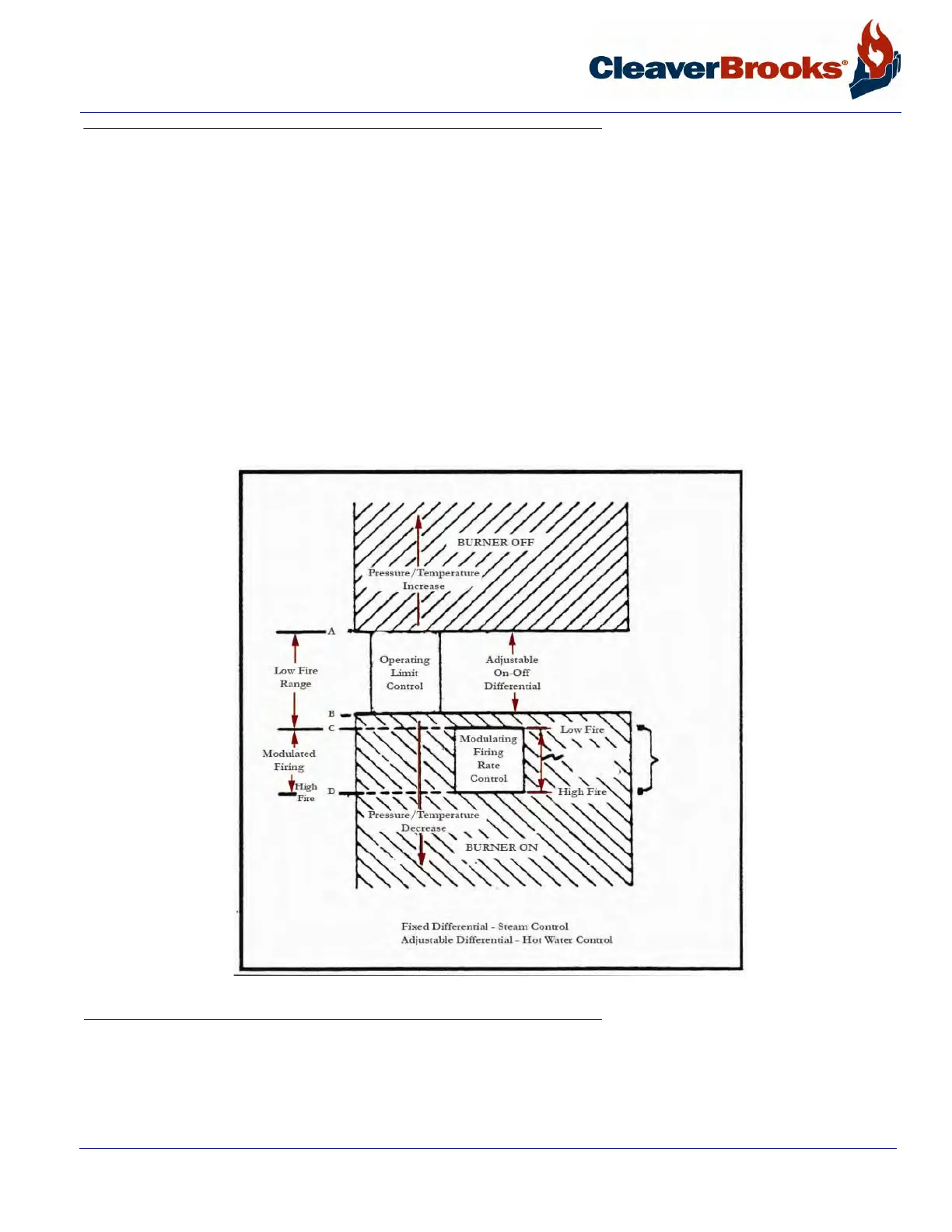

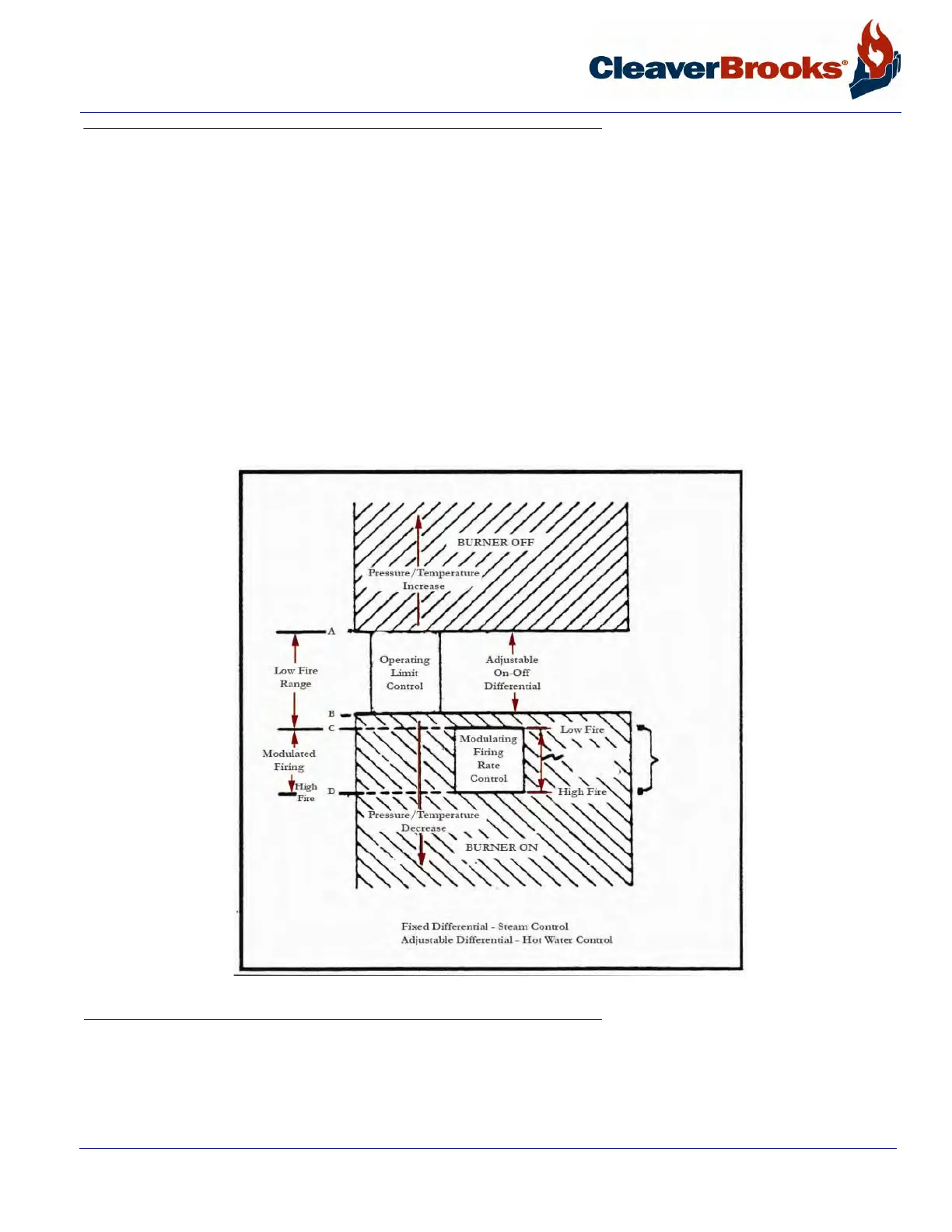

FIGURE 5-4. Operating Control and Modulating Actions

Figure 5-4 depicts a typical relationship of the setting of the operating limit control and the modulating control.

Please note that this is not drawn to any scale. The burner will be “on” whenever the pressure or temperature is

below point B and “off” whenever pressure or temperature is above point A. The distance between points A and B

represents the “on-off” differential of the operating limit control.

Loading...

Loading...