750-96 (revised 2010)

Model CB Packaged Boiler Manual

7-21

7.17 — Opening and Closing Rear Head

7.17 — Opening and Closing Rear Head

A good seal between the rear head (door) and the pressure vessel is necessary to prevent leakage of combustion

gases, loss of heat, and to aid in obtaining operating efficiency. Leaks can also cause hot spots that can lead to

premature refractory failure and/or damage to the door metal.

When opening the door, either for routine maintenance or for an annual inspection, do not do so when the boiler or

the head is hot. The refractory will hold its temperature for some time and exposure to ambient temperature or

rapid cooling may cause refractory cracking and/or harm to the boiler and door metal.

The opened door should be supported by blocking or jacking to eliminate possible deformation.

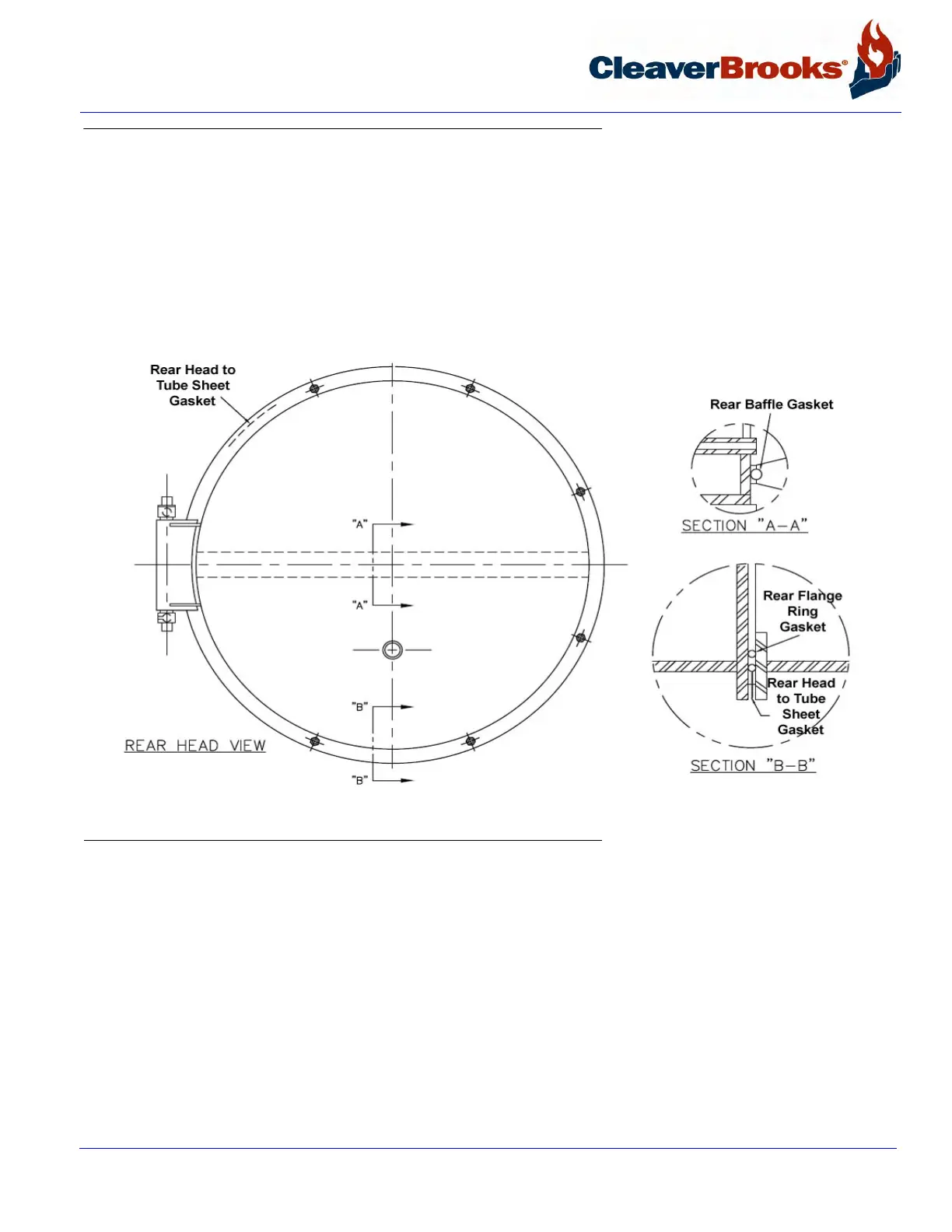

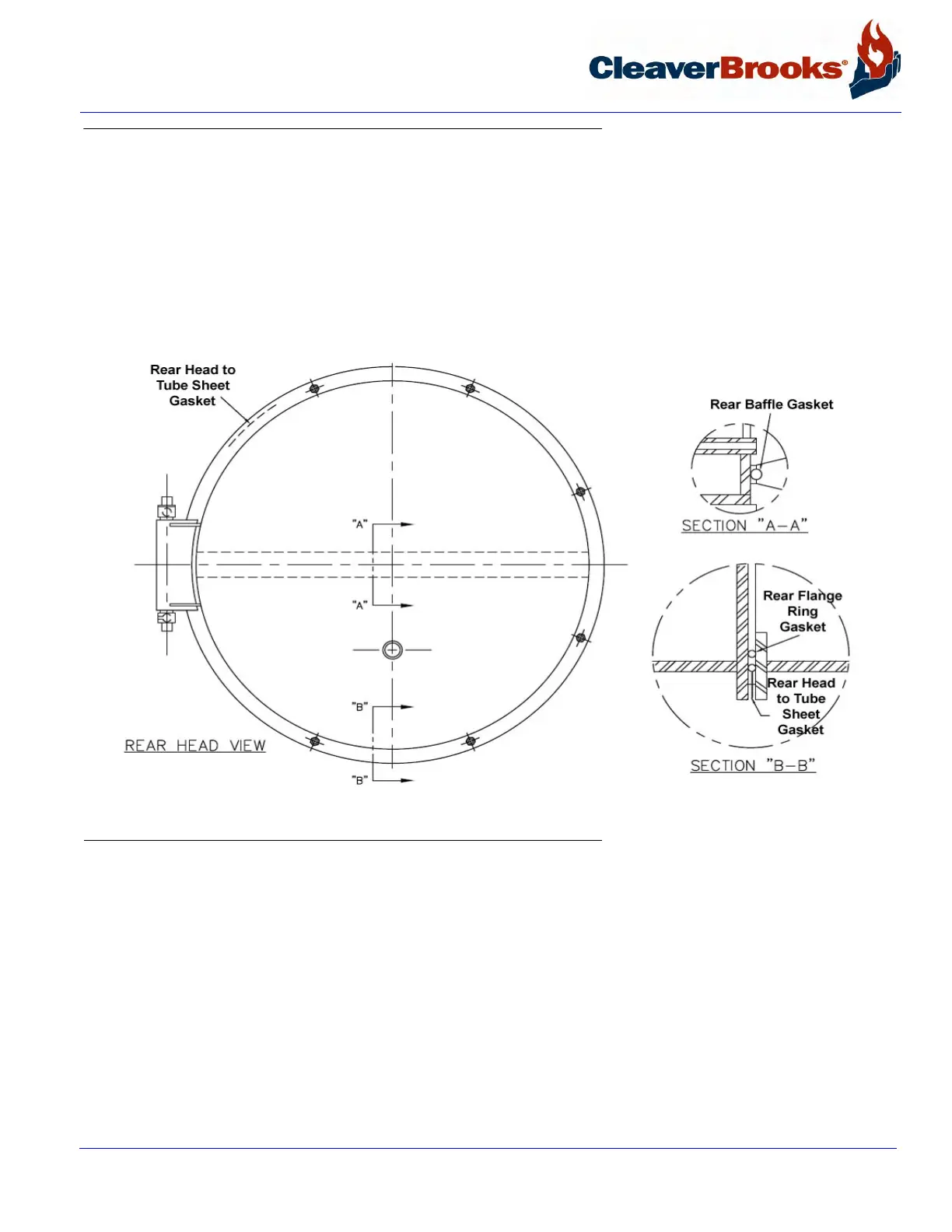

FIGURE 7-10. Rear Door Sealing

Prior to closing, check all gaskets and sealing surfaces. If the door gasket is hard or brittle, it should be replaced.

The fiberglass ropes used for the baffle seal and for the door gasket seal should not be reused. The door flange

and the tube sheet area of the baffle seal should be clean and free of old sealing material, scale, etc. Make sure

that all of the gasket retaining fasteners are in place.

Remove the old rope and insulating cement from the baffle tile or refractory. Be careful not to chip or crack the

refractory. The rope is placed on top of the lip of the tile baffle.

Attach a new length of 1-1/4” diameter fiberglass rope (P/N 853-982) to the baffle. Be certain that it is properly

positioned and use a rapid setting adhesive (P/N 872-481) to hold it in place.

Loading...

Loading...