Inspection and Maintenance

7-16

750-96 (revised 2010)

Model CB Packaged Boiler Manual

7.15.6 — Lube Oil Cooling Coil

The fins on the tubing must be kept clean and free of any dust or dirt that would impede air flow and cause over-

heating. Use an air hose to blow away debris. Internal cleaning of the tubes is seldom required if a good quality

lube oil is used.

7.15.7 — Flexible Coupling Alignment

Alignment of the pump and motor through the flexible coupling is of extreme importance for trouble-free operation

Check coupling alignment frequently and replace the coupling insert as required. Keep coupling guard in place.

The most commonly used tools for checking alignment are a small straightedge and a thickness gauge.

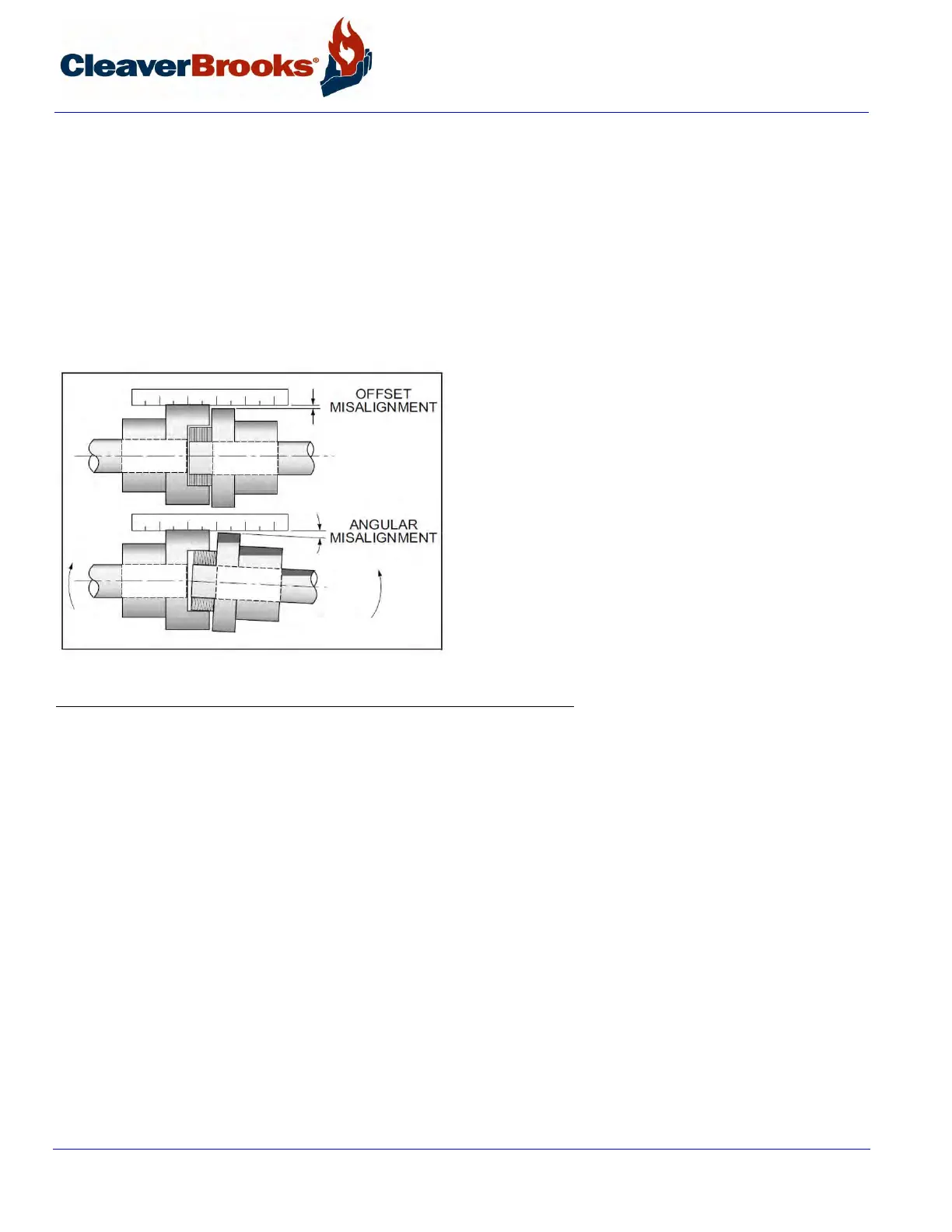

The coupling must be checked for both parallel (offset)

alignment and angular (gap) alignment. Parallel misalign-

ment exists when shaft axes are parallel but not concen-

tric. Angular misalignment is the reverse situation, the

shaft axes are concentric but not parallel.

Checking parallel alignment, both horizontal and vertical,

can be accomplished by laying a straightedge across the

coupling halves and checking with a thickness gauge to

obtain the amount of misalignment. This check should be

done on top of the coupling and at least one 90º interval.

It is helpful to hold a flashlight behind the straightedge so

that any gap can be readily seen.

FIGURE 7-8. Flexible Coupling Alignment

Shim stock of appropriate thickness and area is then used under either the feet of the pump or the motor to estab-

lish parallel alignment. A tolerance of .008” is a permissible limit.

After parallel alignment is established, check for angular alignment. This is done by checking the gap between

coupling halves. The coupling should have a minimum gap of 1/16” and a maximum of 3/32”.

Set the spacing between the halves one point by using a thickness gauge and then rotate the coupling slowly to be

sure that the halves are the same distance apart at all points. Adjust to obtain proper gap by loosening the hold-

down bolts and shifting either the pump or the motor as required. Generally, a slight tapping on either the front or

rear legs is all that is needed to obtain lateral adjustment. Rear legs may require shimming for vertical correction.

Tighten the hold-down bolts after adjustments are made.

Calipers can also be used in checking angular alignment. Measure the overall distance of the outer ends of the

coupling halves at 90º intervals. Shift the pump or motor as required so that the ends of the coupling are the same

distance apart at all points. The coupling will then have proper angular alignment.

Remember that alignment in one direction may alter the alignment in another. Recheck thoroughly both angular

and parallel alignment procedures after making any alterations.

Loading...

Loading...