750-96 (revised 2010)

Model CB Packaged Boiler Manual

2-3

2.3 — Water Requirements

2.3.1.4 — Continuous Flow Through the Boiler

The system should be piped and the controls so arranged that there will be water circulation through the boiler

under all operating conditions. The operation of three-way valves and system controls should be checked to make

sure that the boiler will not be bypassed. Constant circulation through the boiler eliminates the possibility of strati-

fication within the unit and results in more even water temperatures to the system.

A rule of thumb of 1/2 to 1 G.P.M. per boiler horsepower can be used to determine the minimum continuous flow

rate through the boiler under all operating conditions.

Before initial firing or refiring after the boiler has been drained, the operator should determine that a flow of water

exists through the boiler.

2.3.1.5 — Water Circulation

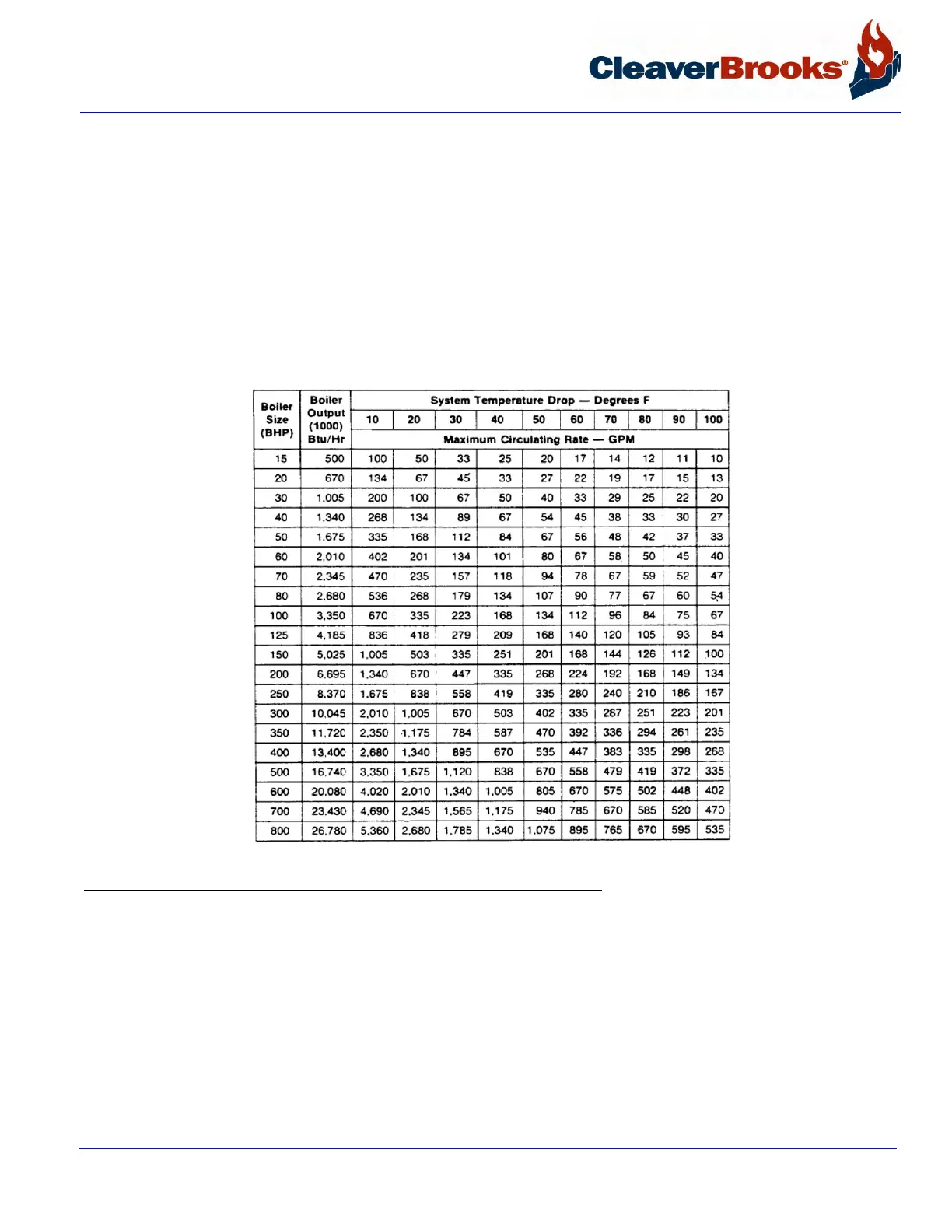

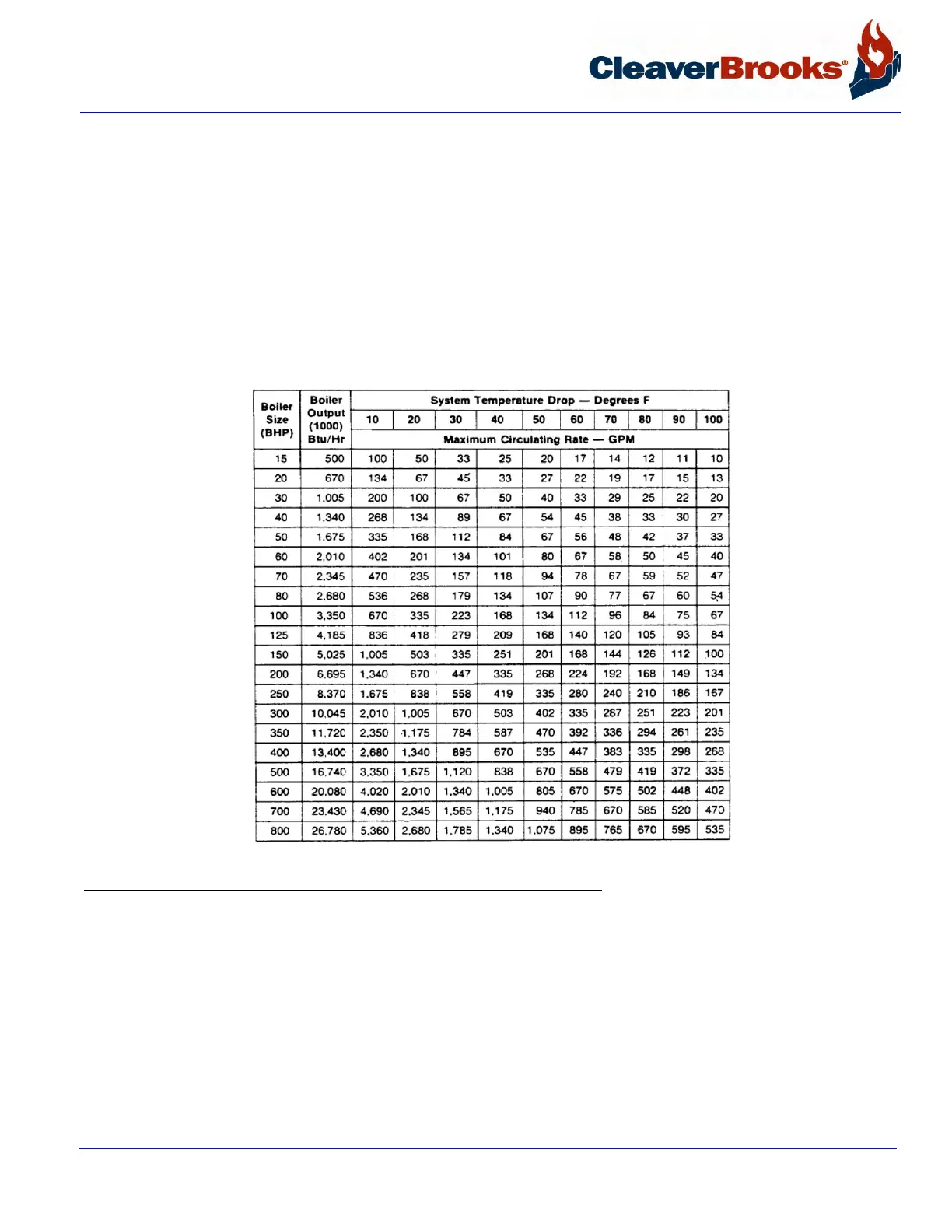

FIGURE 2-1. Circulation Chart

The chart shows the maximum G.P.M. circulation rate of boiler water in relation to full boiler output and system

temperature drop.

2.3.1.6 — Multiple Boiler Installations

When multiple boilers of equal or unequal size are used, care must be taken to insure adequate or proportional

flow through the boilers. This can best be accomplished by use of balancing cocks and gauges in the supply line

from each boiler. If balancing cocks or orifice plates are used, a significant pressure drop (e.g., 3-5 psi) must be

taken across the balancing device to accomplish this purpose.

Loading...

Loading...