Adjustment Procedures

5-12

750-96 (revised 2010)

Model CB Packaged Boiler Manual

The pressures listed are based on 1000 BTU/cu. ft. natural gas at elevations up to 700 feet above sea level. For

installation at higher altitudes, multiply the selected pressure by the proper factor from Table 2.

5.7.2 — Gas Flow

The volume of gas flow is measured in terms of cubic feet and is determined by a meter reading. The gas flow

rate required for maximum boiler output depends on the heating value (BTU/cu. ft.) of the gas supplied. The sup-

plying utility can provide this information.

To obtain the required number of cubic feet per hour of gas, divide the heating value (BTU/cu. ft.) into the required

burner input (BTU/hr.). See Table 3 for input requirements.

5.7.3 — Pressure Correction

The flow rate outlined in the previous section is figured on a “base” pressure which is usually atmospheric or 14.7

psi.

Meters generally measure gas in cubic feet at “line” or supply pressure. The pressure at which each cubic foot is

measured and the correction factor for this pressure must be known in order to convert the quantity indicated by

the meter into the quantity which would be measured at “base” pressure.

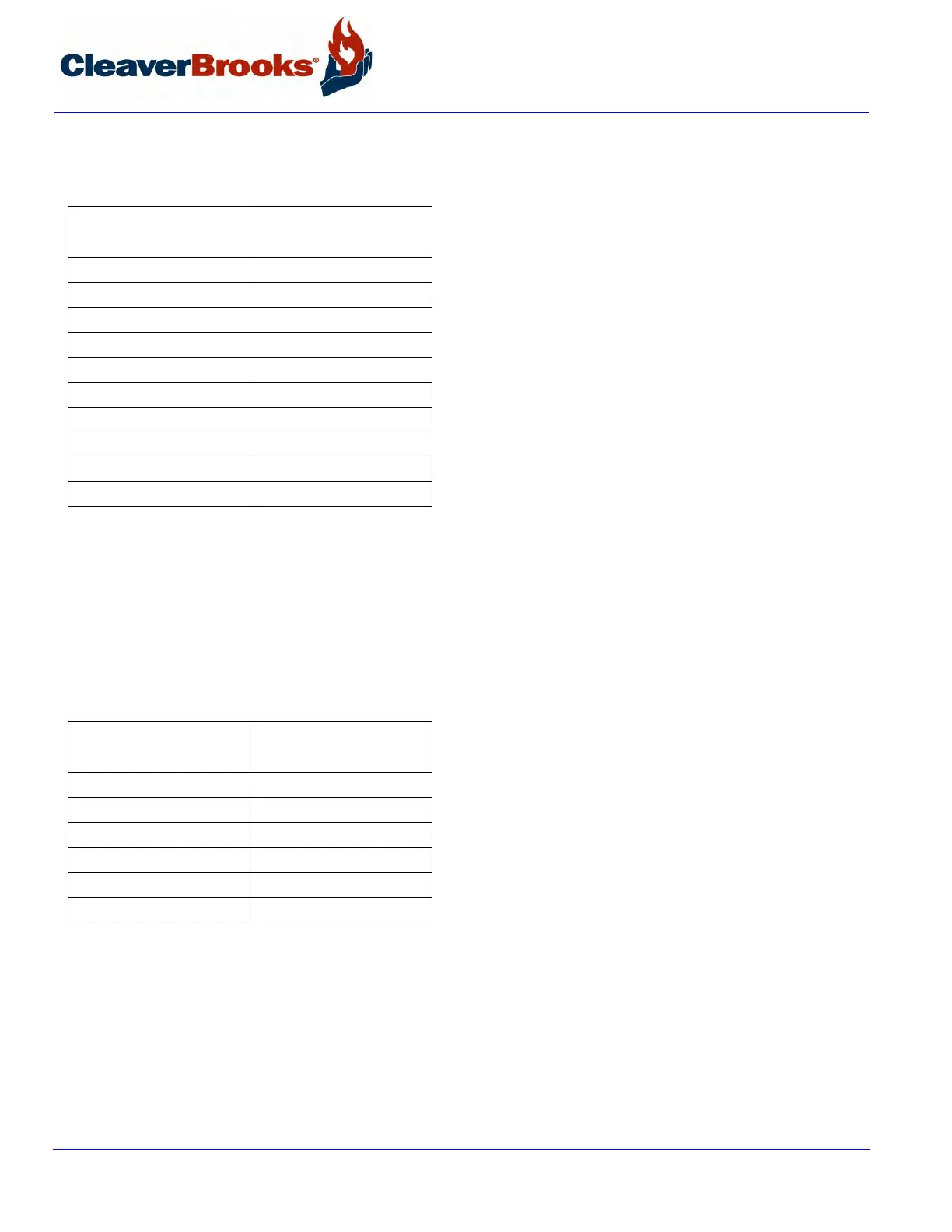

TABLE 2. Higher Altitude Installation Factors

Altitude: Feet Above

Sea Level Correction Factor

1000 1.04

2000 1.13

2500 1.18

3000 1.22

4000 1.33

5000 1.44

6000 1.57

7000 1.70

8000 1.84

9000 2.01

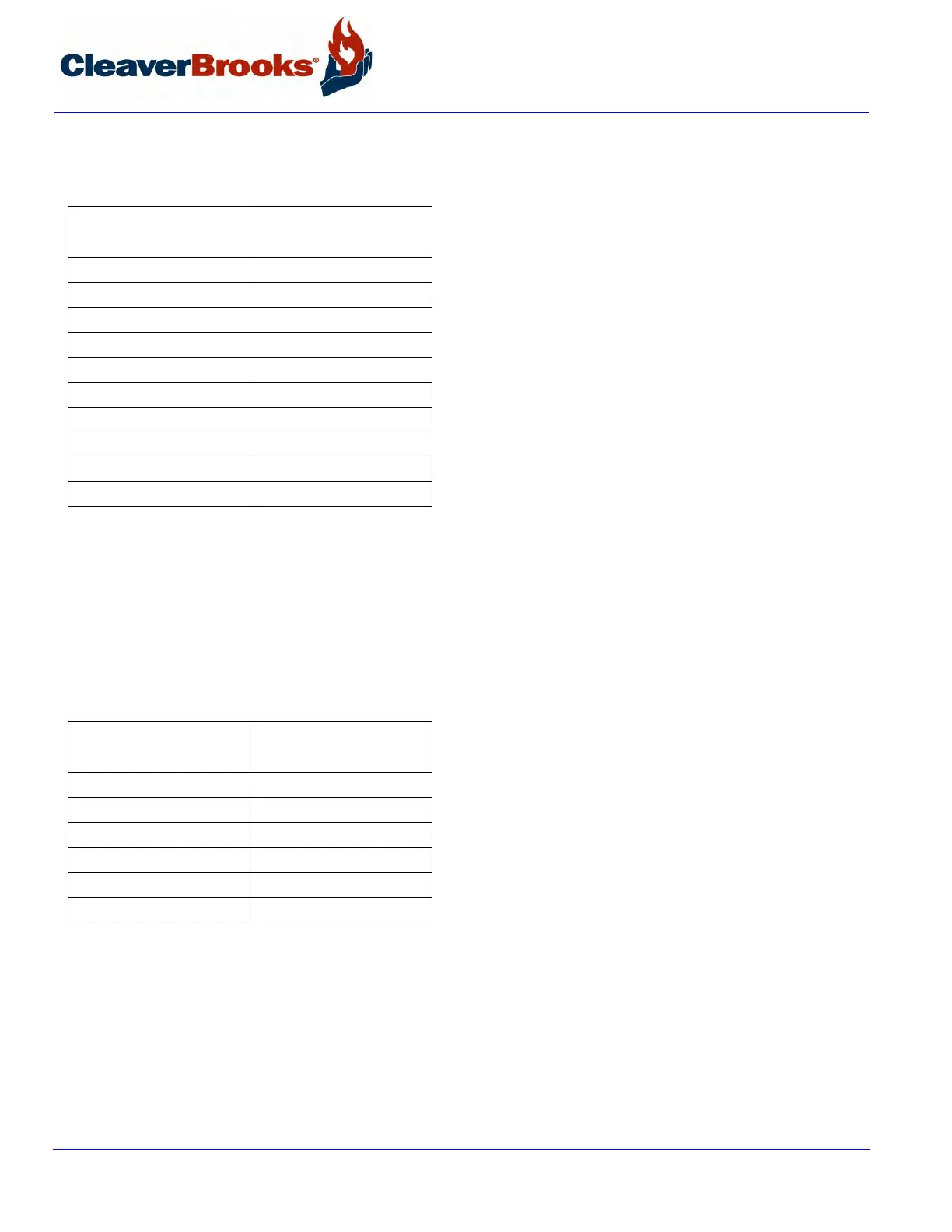

TABLE 3. Input Requirements

Boiler Horsepower

Maximum Input:

BTU/hr.

50 2,092,000

60 2,511,000

70 2,929,000

80 3,347,000

100 4,184,000

125A 5,230,000

Loading...

Loading...