750-96 (revised 2010)

Model CB Packaged Boiler Manual

5-13

5.7 — Gas Pressure and Flow Information

To express the volume obtained from an actual meter reading into cubic feet at base pressure, it is necessary to

multiply the meter index reading by the proper pressure factor obtained from Table 4.

Conversely: To determine what the meter index reading should be in order to provide the volume of gas required

for input, divide the desired flow rate by the proper pressure correction factor. This answer indicates the number

of cubic feet at line pressure which must pass through the meter to deliver the equivalent number of cubic feet at

base pressure.

For example, assume:

• that a 100 horsepower boiler is installed at 2,000 feet above sea level

• is equipped with a standard gas train

• that 1,000 BTU natural gas is available with an incoming gas pressure of 3 psig

The pressure and flow can be determined as follows:

Pressure: Correction for the 2,000 feet altitude must be made since altitude has a bearing on the net regulated

gas pressure.The standard gas train requires 8.5” W.C. gas pressure at sea level. Table 2 indicates a correction

factor of 1.07 for 2,000 feet. Multiplying these results in a calculated net regulated gas requirement of approxi-

mately 9.1” W.C. This is the initial pressure to which the regulator should be adjusted. Slight additional adjustment

can be made later, if necessary, to obtain the gas input needed for burner rating.

Flow: Since the gas flow rate is based on standard conditions of flow, correction must be made for the supply

pressure through the meter of 3 psig. Determine the flow rate by dividing the BTU content of the gas into the

burner input (Table 3) and “correct this answer by applying the correction factor for 3 psig (Table 4).

BTU/hr Input

= CFH (Cubic Feet/Hour)

BTU/cu. ft.

OR

4,184,000

= 4,184 CFH

1,000 (at 14.7 lb. atmospheric “base” pressure)

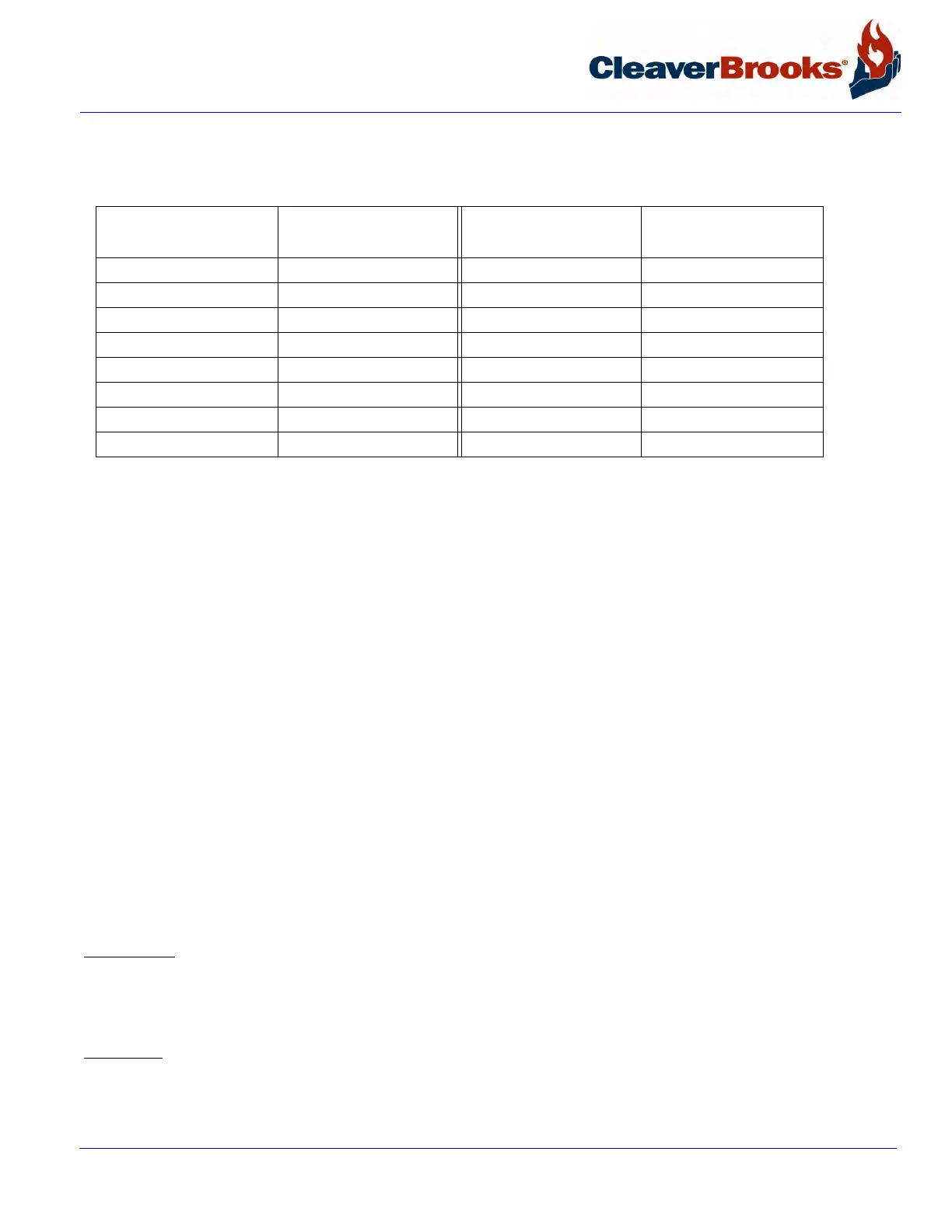

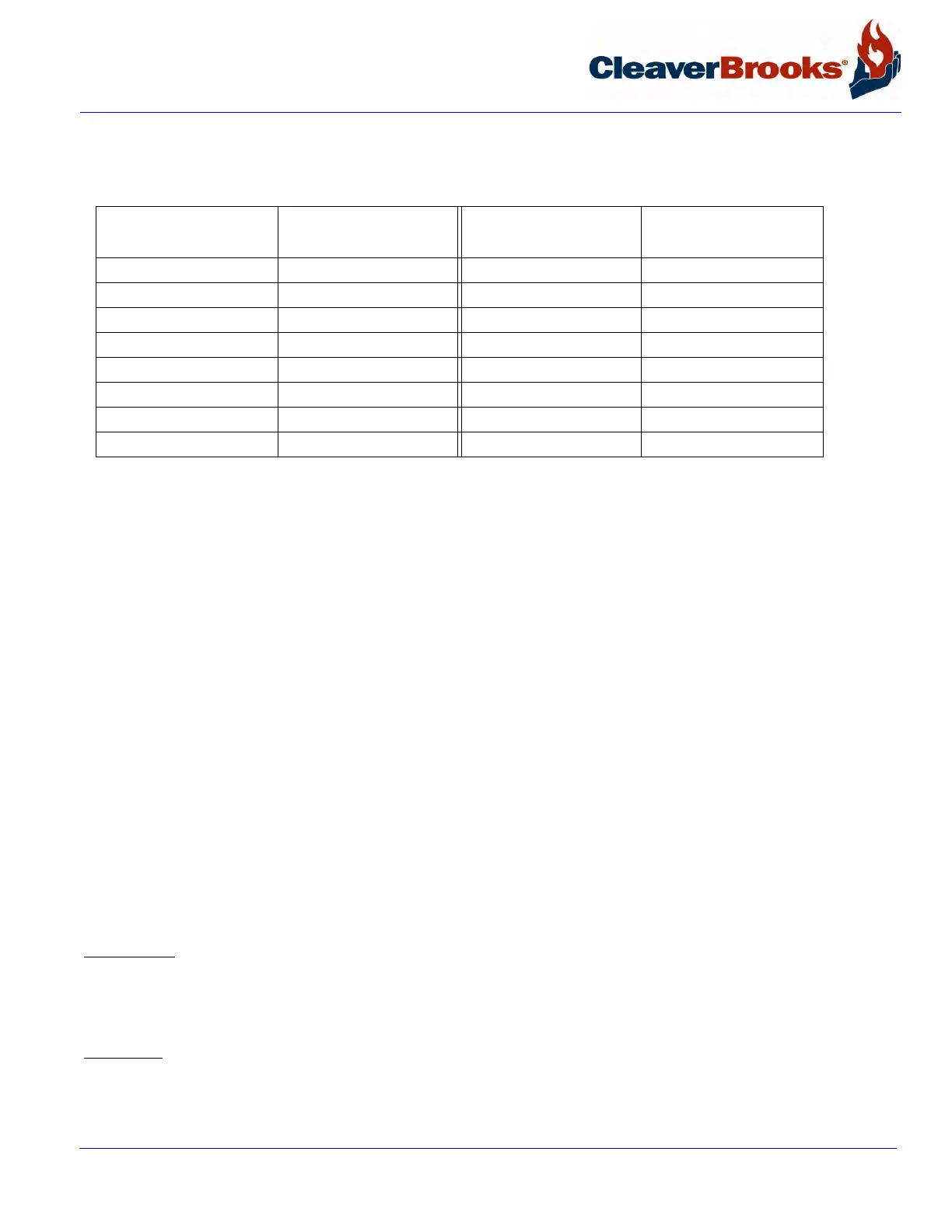

TABLE 4. Pressure Correction Factors

Regulator Inlet

Pressure Pressure Factor

Regulator Inlet

Pressure Pressure Factor

1 psig 1.05 9 psig 1.59

2 psig 1.11 10 psig 1.66

3 psig 1.18 11 psig 1.72

4 psig 1.25 12 psig 1.81

5 psig 1.32 13 psig 1.86

6 psig 1.39 14 psig 1.93

7 psig 1.45 15 psig 2.00

8 psig 1.52

Loading...

Loading...