Starting and Operating Instructions

4-4

750-96 (revised 2010)

Model CB Packaged Boiler Manual

4.5 — Firing Preparations for No. 2 Oil: Series 100-200

Prior to initial firing, oil flow and pressure should be established and verified. Atomizing air pressure should also be

established as outline in Section 4.4. The schematic flow diagram in Chapter 1 indicates the flow of fuel and atom-

izing air.

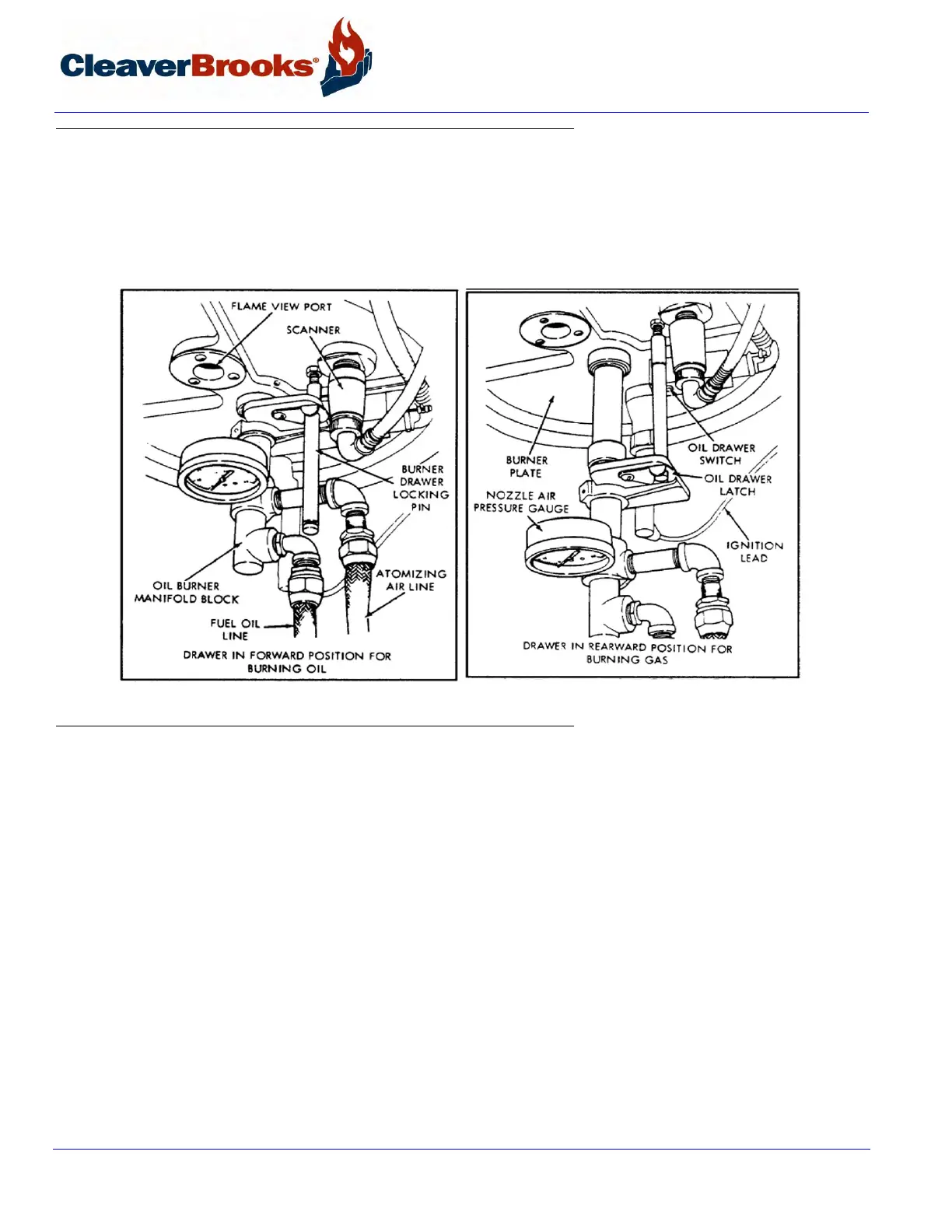

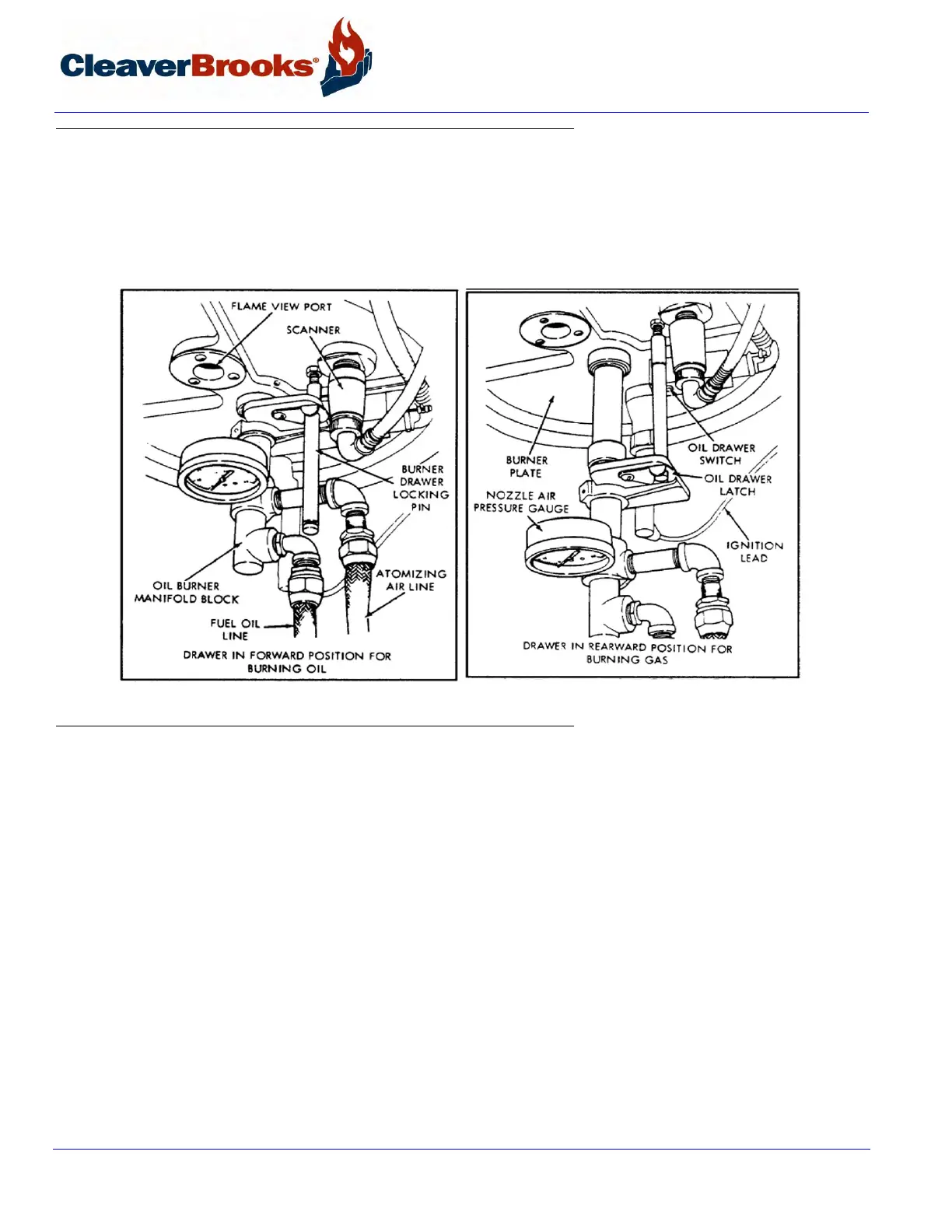

If the burner is a combination fuel model, make certain that the main gas shutoff cock is closed and set the gas/

oil selector switch to “oil.” Insert the burner drawer gin into its most forward position and latch it in place.

FIGURE 4-1. Positions of Burner Drawer for Oil and Gas

4.5.1 — Oil Flow

Open all valves in the oil suction and oil return lines.

If the oil supply tank is located above the level of the pump and flow to the pump is be gravity, then it will usually

be necessary to vent the suction line to allow oil to fill the line. This can generally be accomplished by cracking a

union fitting, or by opening the cap of the oil strainer using care to prevent spillage of oil. Tighten the fitting or cap

as soon as oil flow appears.

If the oil supply tank is below the level of the oil pump, it is mandatory that the suction line to the pump be com-

pletely filled with oil prior to starting the pump to avoid the possibility of damage to the pump gears through oper-

ation without the lubrication afforded by the fuel oil. Non-lubricating fluids such as kerosene should not be used for

priming.

Prior to priming the suction line and the initial start, check to make certain that all plugs, connections, etc., have

been securely tightened to prevent leaks.

Loading...

Loading...