THE SMART SOLUTION FOR ENERGY EFFICIENCY

Tranquility

®

Compact Belt Drive (TCH/V) Series

Rev.: July 25, 2017

17

climatemaster.com

Figure 2: Horizontal Unit Pitch

1/4” (6.4mm) pitch

toward drain for drainage

Drain Connection

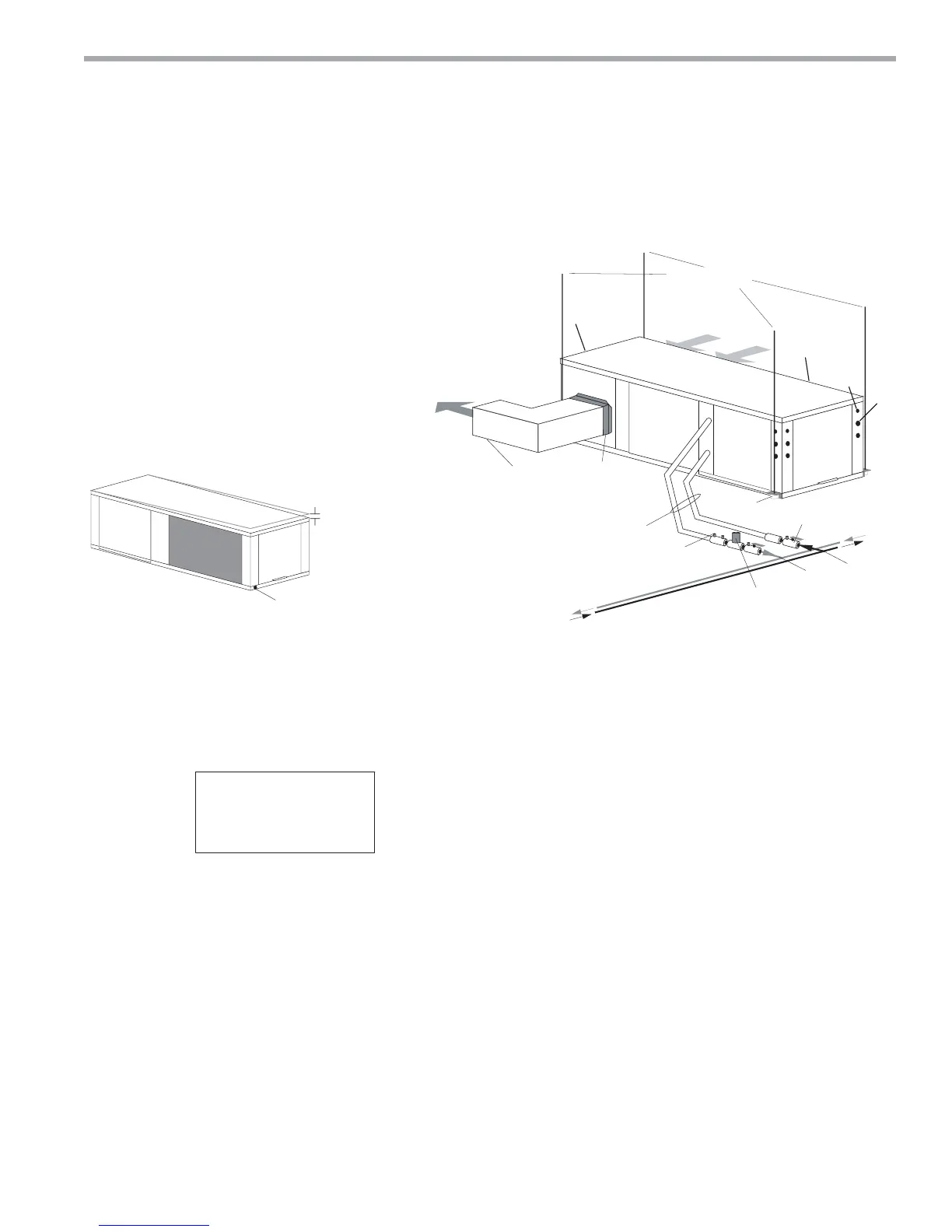

Figure 3: Typical Horizontal Unit Installation

Air Coil - To obtain maximum performance, the air coil

should be cleaned before start-up. A 10% solution of

dishwasher detergent and water is recommended for

both sides of the coil. A thorough water rinse should

follow. UV based anti-bacterial systems may damage

coated air coils.

Notice! Installation Note - Ducted Return: Many

horizontal WSHPs are installed in a return air ceiling

plenum application (above ceiling). Vertical WSHPs are

commonly installed in a mechanical room with free return

(e.g. louvered door). Therefore, fi lter rails are the industry

standard and are included on ClimateMaster commercial

heat pumps for the purposes of holding the fi lter only.

For ducted return applications, the fi lter rail must be

removed and replaced with a duct fl ange or fi lter frame.

Canvas or fl exible connectors should also be used to

minimize vibration between the unit and ductwork.

(by others)

Thermostat

Wiring

Insulated supply duct with

at least one 90 deg elbow

to reduce air noise

Return Air

Supply Air

Unit Hanger

3/8" [10mm] threaded rods

Flexible Duct

Connector

Optional

Balancing Valve

Water Out

Optional Low Pressure Drop Water

Control Valve

Stainless steel braid hose

with integral “J” swivel

Building

Loop

Water In

Ball valve with optional

integral P/T plug

Unit

Power

CAP

CAP

EAP

BSP

CBP

LEGEND

CAP=Compressor Access Panel

CBP=Control Box Panel

BSP=Blower Service Panel

EAP=Expansion Valve Access panel

1=Water Outlet 1-1/4” FPT (072-096) 1-1/2” FPT (120)

2=Water Inlet 1-1/4” FPT (072-096) 1-1/2” FPT (120)

3=Condensate 3/4” FPT

4=High Voltage 1-1/8” [2.9cm] KO

5=Low Voltage 7/8” [2.2cm] KO

NOTES:

-

All dimensions in table are inches (cm).

6HUYLFHDccess is required for all removable panels and installer should take care to comply with all building codes and

allowadequate clearance for future field service.

Water inlet and water outlet connections are available on either side (left or right) of the unit. Qty (2x) MPT Plugs are

shipped loose in a plastic bag tied to the water leg in front of the unit. Installer must plug water inlet/outlet side not being

connected to.

&RQGHQVDWHGUDLQLV)37DQGLVORFDWHGRQFDELQHWHQGRSSRVLWHWKHFRPSUHVVRU

Electrical access is available on either side (left or right) of the front.

Electric box is on right side. It can be field converted to left side. Conversion should only be attempted by qualified

service technician. If electric box relocated to opposite side, and water connected to opposite side, then this access is

not required.

Units require 3’ (9.1 cm) clearance for water connections, CAP, C%P, EAP and BSP service access.

Overall cabinet width dimensions does not include filter rail and duct flange.

8QLWVDUHVKLSSHGZLWKDLUILOWHUUDLOVWKDWDUHQRWVXLWDEOHIRUVXSSRUWLQJUHWXUQDLUGXFWZRUN$QDLUILOWHUIUDPHZLWKGXFW

PRXQWLQJFROODULVDYDLODEOHDVDQDFFHVVRU\

Loading...

Loading...