THE SMART SOLUTION FOR ENERGY EFFICIENCY

Tranquility

®

Compact Belt Drive (TCH/V) Series

Rev.: July 25, 2017

31

climatemaster.com

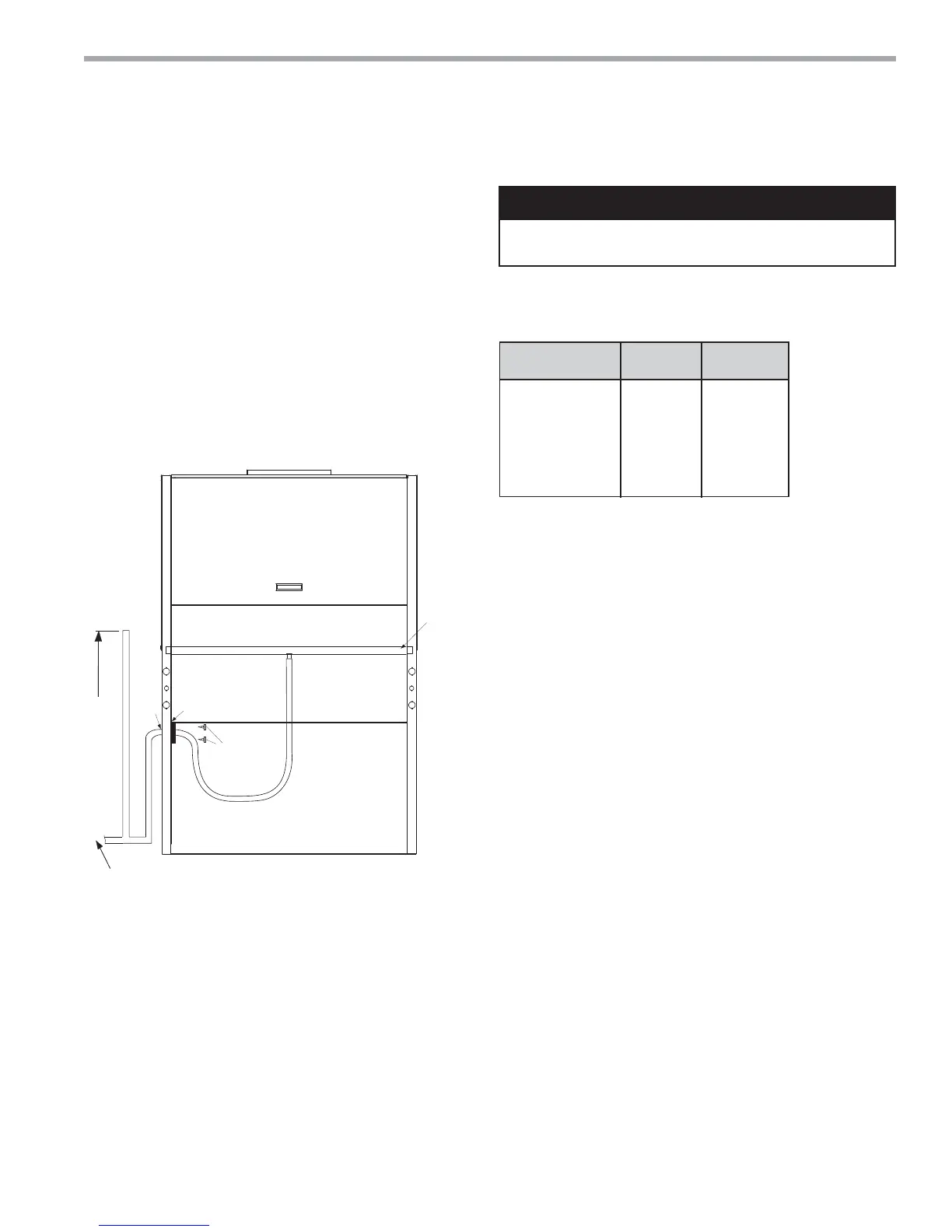

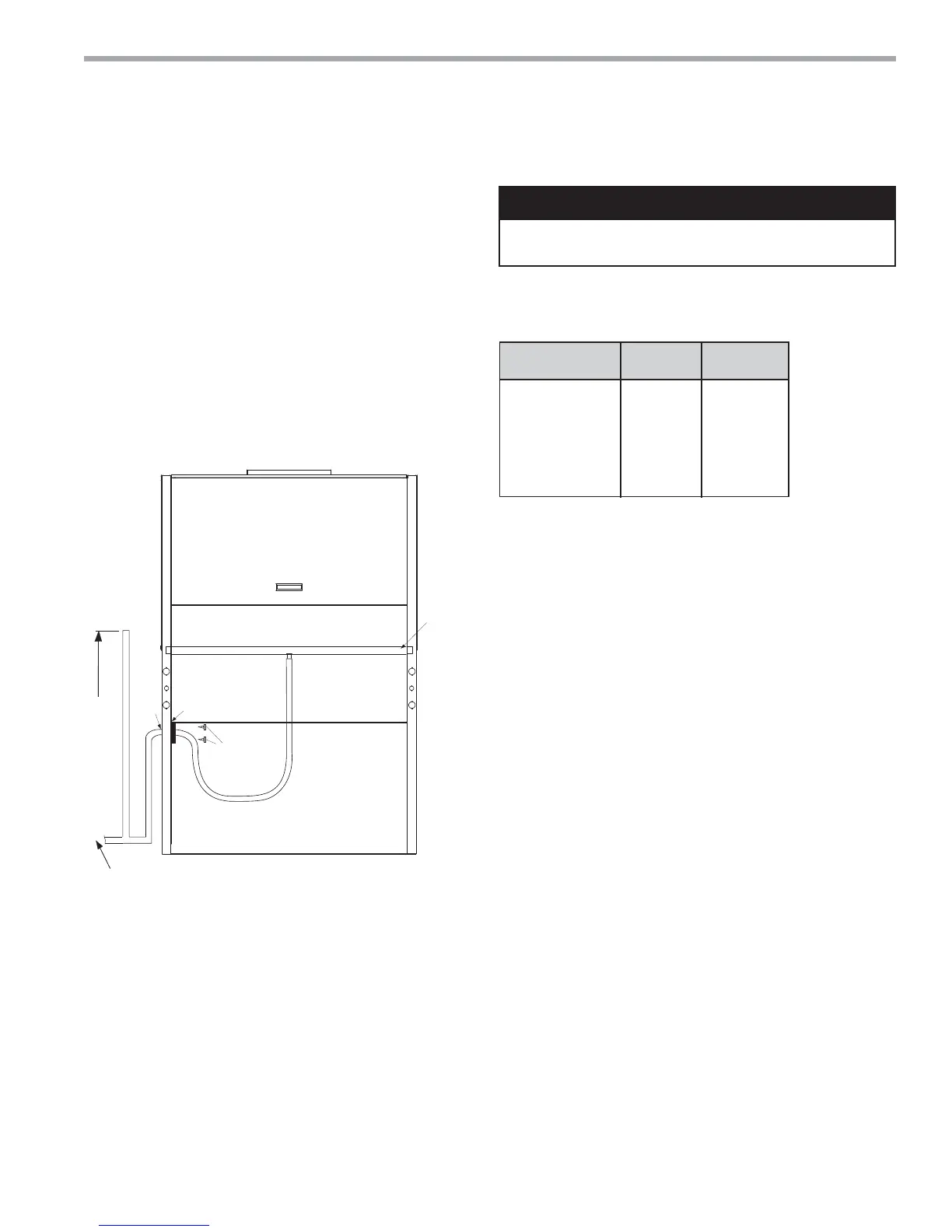

Condensate Piping - TCV - Remove KO on side that

drain will be connected. Remove access panels. Inside

of unit, untie and uncoil drain hose. Form trap in hose,

make sure hose is not kinked or deformed. Connect plate

assembly to side frame with 2 screws.

Outside of unit, connect 1” MPT fi tting to plate assembly.

Run line to building drain. Horizontal runs must be

pitched ¼” per foot (10 mm per 46 cm) toward drain. Do

not trap externally.

Figure 10 illustrates a typical trap and vent used with TCV

series equipment.

Each unit must be installed with its own individual line to

the building main condensate drain line or riser. Provide

a means to fl ush or blow out the condensate line. DO

NOT install units with a common trap and or vent. Always

vent the condensate line when dirt or air can collect in

the line or a long horizontal drain line is required. Also

vent when large units are working against higher external

static pressure than other units connected to the same

condensate main since this may cause poor drainage

for all units on the line. WHEN A VENT IS INSTALLED IN

THE DRAIN LINE, IT MUST BE LOCATED AFTER THE

TRAP IN THE DIRECTION OF THE CONDENSATE FLOW

and opening 46” (117 cm) minimum from bottom of unit.

(Vent per code)

m] drain slope

Pipe Connected Connected

Size Tons kW

3/4” [19mm] <4 <14

1” [25mm] <6 <21

1-1/4” [32mm] <30 <105

1-1/2” [38mm] <50 <175

2” [51mm] <150 <527

3” [76mm] <300 <1055

4” [102mm] <500 <1758

* Make sure all connections are secure and

water tight.

WARNING!

WARNING! Ensure condensate line is pitched toward drain

1/4" per foot [10mm per 46cm] of run.

Vertical Condensate Installation

All fittings and tubing outside of the unit are field supplied.

Condensate

Pan

1” IPT

2 Screws

Open

Vent

1” EPT

Fitting

46” Min

To Bottom

Of Unit

To main

drain, pitch

¼” Per foot

Figure 10: TCV

Horizontal and Vertical Installations - Drain main or

riser must be sized for all units connected to it.

After drain is connected to main and all drain

connections are secure and water tight, pour 1 gallon of

water into condensate pan. Water should drain out freely.

Repair any leaks.

• On units with multiple fan outlets a “pair of pants”

duct connection must be used for proper air balance

and distribution and to prevent fan oscillation.

• Include at least one 90-degree turn in supply air ducts

to reduce noise transmission.

• Existing ducts must be checked to ensure proper

size and configuration prior to installation of any

replacement unit. Also inspect for and repair all air

leaks in existing ducts.

• Units may only be connected to a dedicated duct

system. Consult the factory BEFORE connecting

multiple units to a common duct system.

• Never connect a unit to a duct system with automatic

or modulating dampers, VAV boxes, etc. in the supply

air system. Never allow a situation where the total unit

CFM can drop below the minimum required for proper

unit operation.

• Never connect a bypass damper from the supply air

duct to the return air duct. Never allow the return air

temperature to drop below the minimum allowable

normal temperature for proper unit operation.

• Do not use TC units for 100% outdoor air treatment.

Do not add hot-gas-bypass to “convert” a unit

for outdoor air treatment. Always use a dedicated

outdoor air unit for outdoor air treatment.

• Do not exceed 10% of the total unit CFM with

untreated outdoor air.

Loading...

Loading...