22

00001996 (REV AC) 627NH October 2014

If allowed to cool, the solid state switch will return to normal

operation. However, before returning the hoist to service,

the following procedure should be used to determine if the

switch has been damaged.

1. De-energize the power system supplying the hoist and

remove the solid state reverse switch.

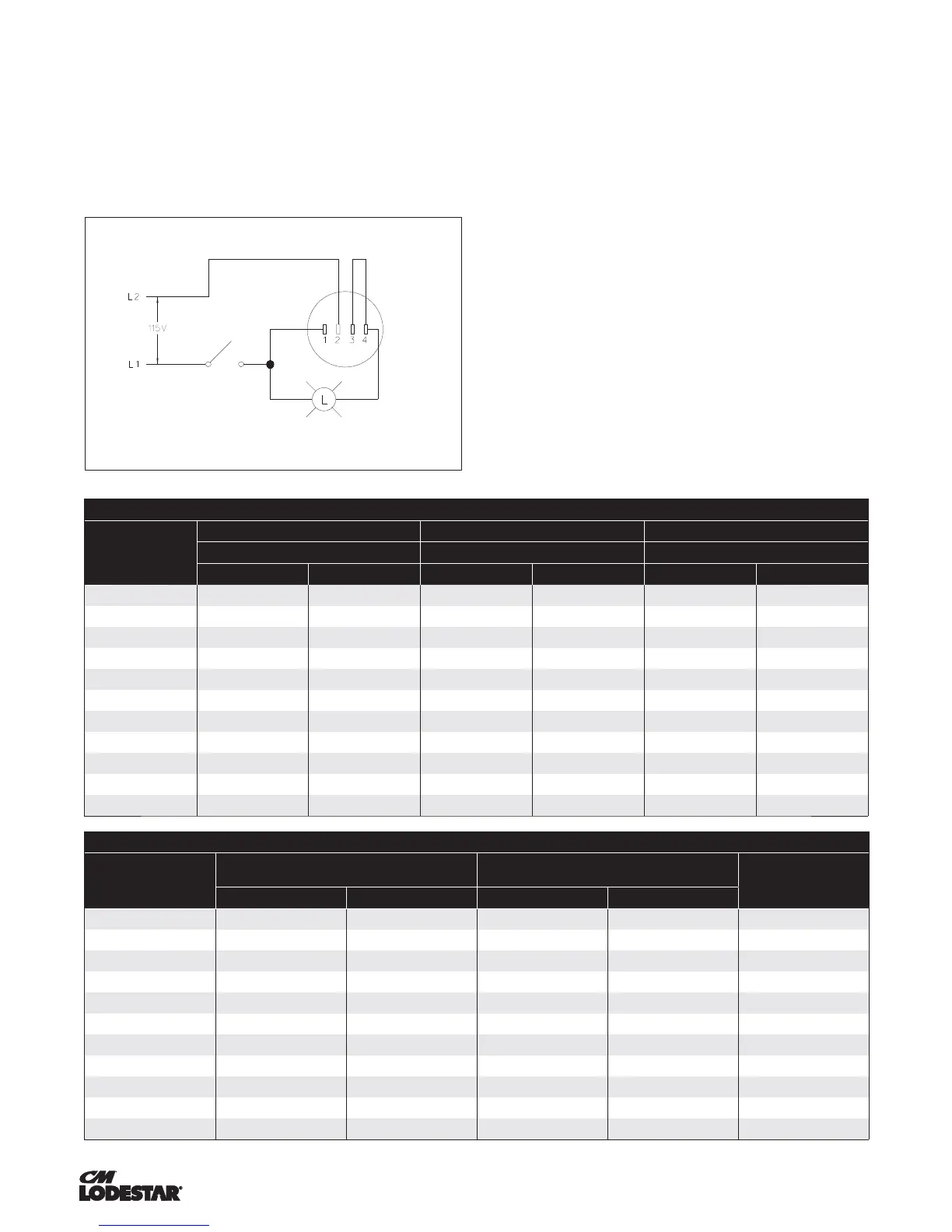

2. Connect the solid state reverse switch to a 115-1-60/230-

1-60 light circuit as shown below.

3. Close the switch to energize the 115-1-60/230-1-60

power supply. The light bulb will illuminate if the solid

state reverse switch is not damaged. If the bulb fails to

illuminate, the switch is damaged and must be replaced.

4. Turn the 115-1-60/230-1-60 power off and remove the

solid state reverse switch from the test circuit.

Reinstall the solid state reverse switch in the hoist and re-

connect it using the wiring diagram supplied with the hoist.

Re-energize the power system supplying the hoist and test

for proper operation. Also, ventilate the space around the

hoist and/or reduce duty cycle, excessive starting, excessive

plugging to reduce future malfunctions of the solid state

reverse due to overheating.

BRAKE ADJUSTMENTS

DC ELECTRIC BRAKE ASSEMBLY

The correct air gap between fi eld and armature is .008-.018

in (0.2-0.45 mm) for models A through H and .008-,020 in

(0.2- 0.5 mm) for models J through RRT. The DC brake is

not adjustable. As the friction material wears, the brake gap

increases. If the maximum air gap is reached, a new friction

disc/rotor should be installed.

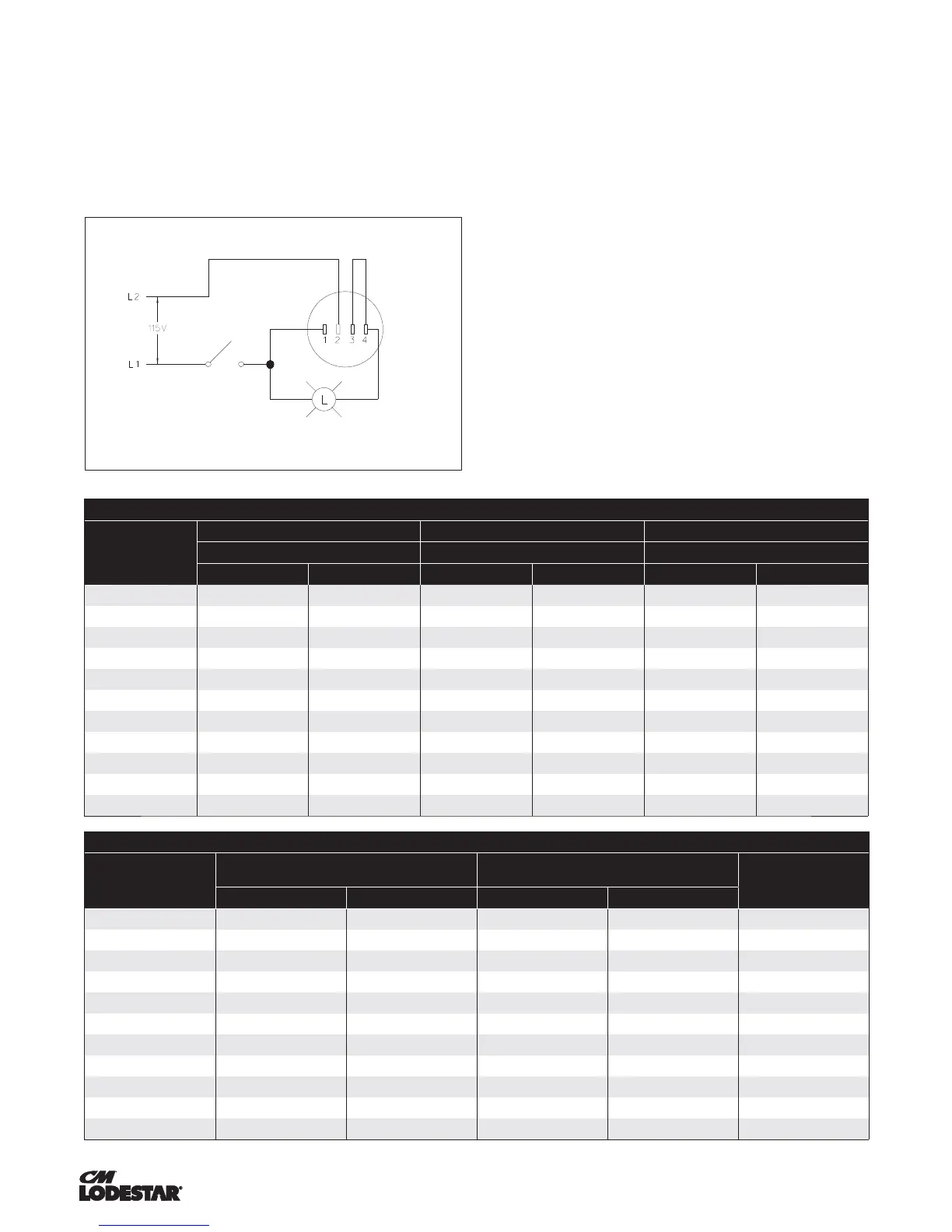

Table 6a. Limit Switches

Model

Hook Travel w/ 44 T.P.I. Shaft (Standard) Hook Travel w/ 56 T.P.I. Shaft (Standard) Hook Travel w/ 64 T.P.I. Shaft (Standard)

Max Length of Lift Max Length of Lift Max Length of Lift

mftmftmft

A, A-2, C, C-2 63 206 80 262 91 299

AA, AA-2 117 385 150 491 171 561

B, B-2, F, F-2 32 105 41 133 46 152

E, E-2, H, H-2 16 52 20 67 23 76

L, L-2, J, J-2 39 127 49 162 56 185

JJ, JJ-2, LL, LL-2 76 250 97 318 111 363

R, R-2 20 64 25 81 28 93

RR, RR-2 38 124 48 158 55 181

RT, RT-2 13 42 16 54 19 62

RRT, RRT-T 25 83 32 106 37 121

RRS

38 125 48 159 55 182

Table 6b. Limit Switches

Model

Hook Travel, per Notch

A (minimum distance between top

of hook block and bottom of hoist)

B (minimum length of

loose end chain)

mm in mm in

A, A-2, C, C-2 52.8 2.08 38.1 1.50 6 links

AA, AA-2 98.8 3.89 50.8 2.00 6 links

B, B-2, F, F-2 26.9 1.06 38.1 1.50 6 links

E, E-2, H, H-2 13.5 0.53 44.45 1.75 6 links

L, L-2, J, J-2 30.5 1.20 38.1 1.50 8 links

JJ, JJ-2, LL, LL-2 116.8 4.60 63.5 2.50 8 links

R, R-2 15.2 0.60 63.5 2.50 8 links

RR, RR-2 29.7 1.17 63.5 2.50 8 links

RT, RT-2 10.2 0.40 63.5 2.50 8 links

RRT, RRT-T 19.8 0.78 63.5 2.50 8 links

RRS

30.0 1.18 63.5 2.50 2.50 in

Loading...

Loading...