Parameter

structure

Keypad and

display

Parameter x.00

Parameter

description format

Advanced parameter

descriptions

Serial comms

protocol

Electronic

nameplate

Performance

Menu 3

Digitax ST Advanced User Guide 59

Issue Number: 1 www.controltechniques.com

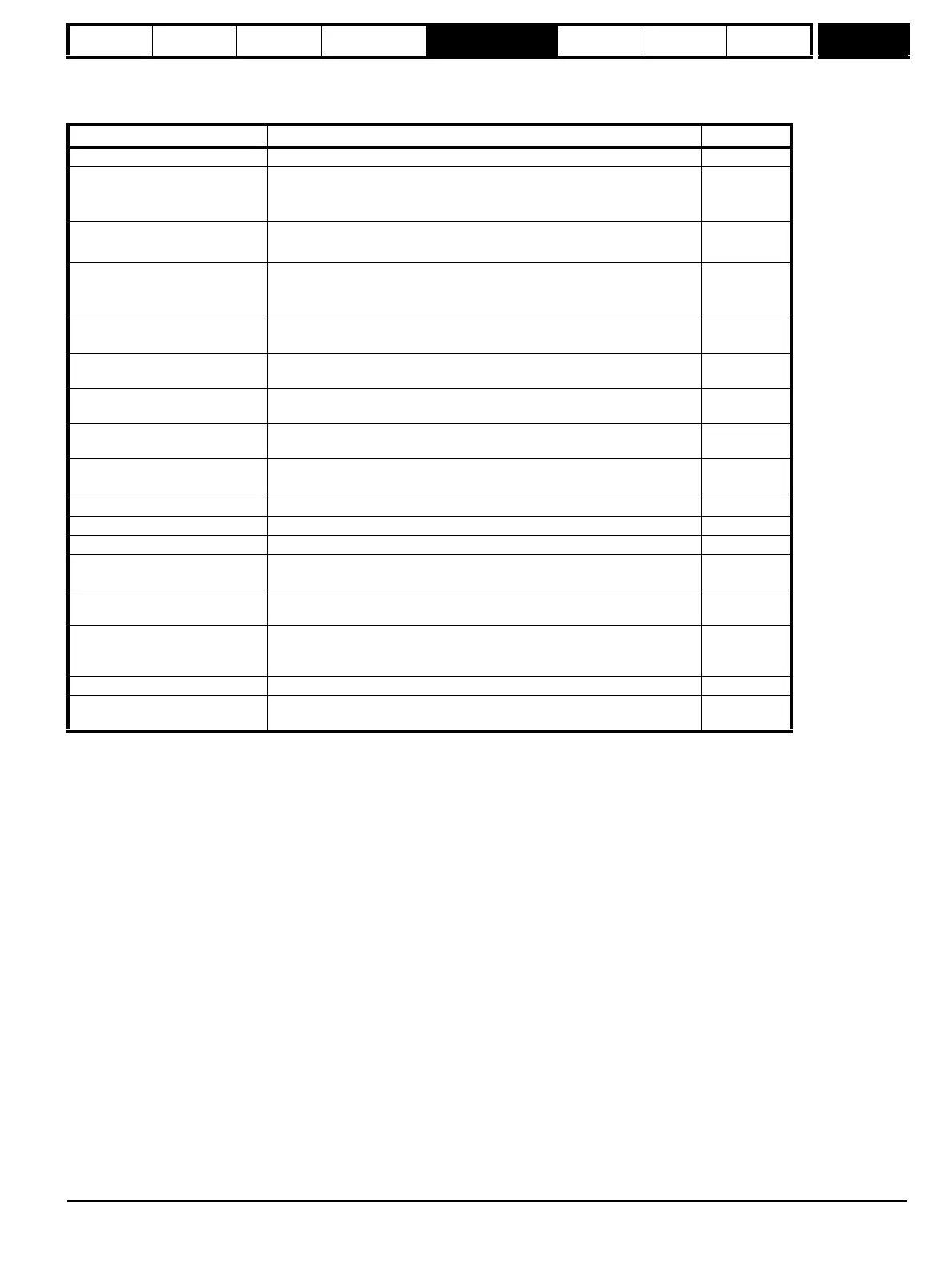

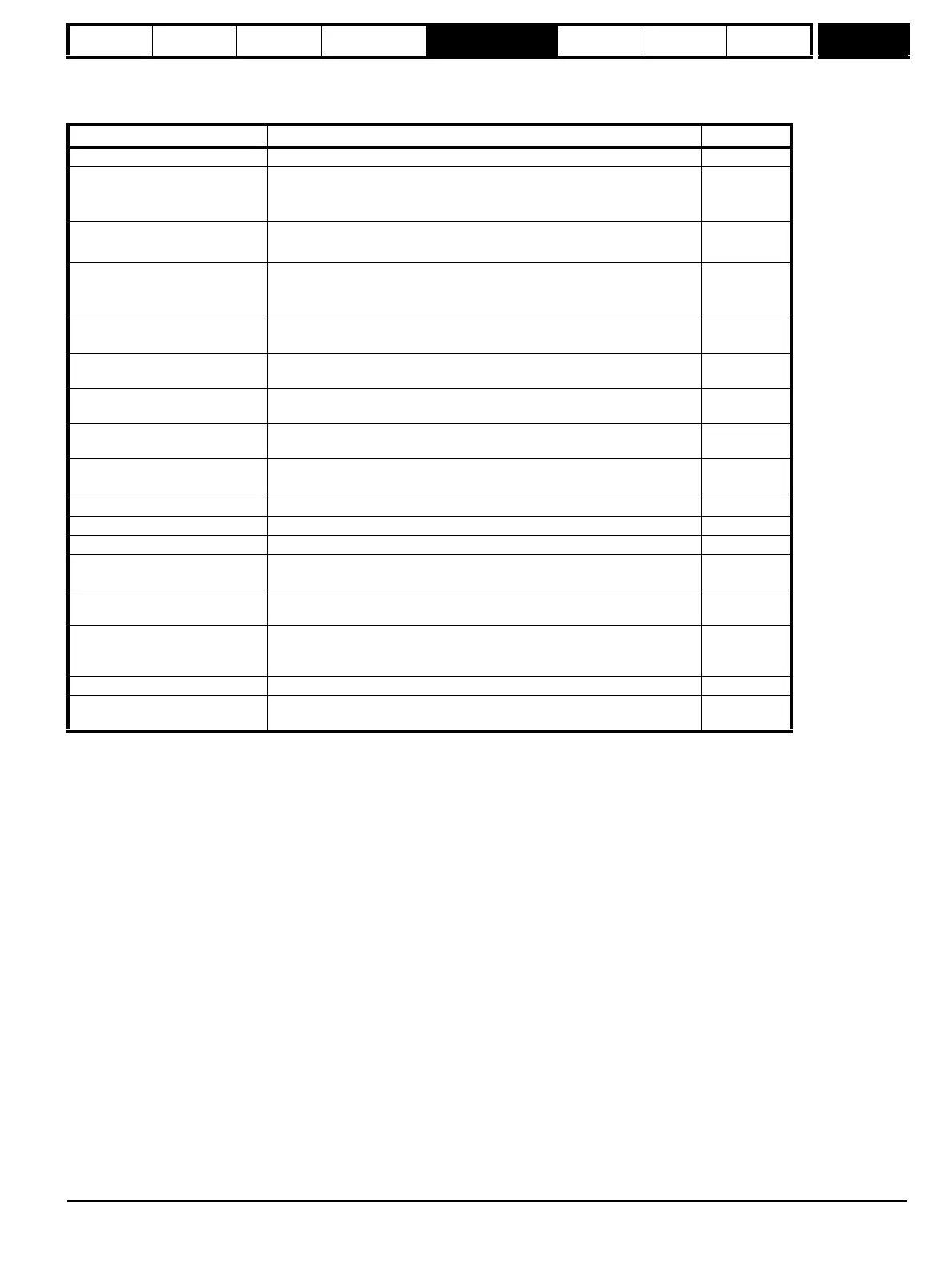

Encoder trips

The following table shows trips that can be initiated that are related to the drive encoder feedback and whether they can be enabled and disabled by

Pr 3.40.

+These trips can be enabled/disabled by Pr 3.40

1. If the terminations are not enabled on the A, B or Z inputs the wire break system will not operate. (Note that as default the Z input terminations

are disabled to disable wire break detection on this input). No wire break detection is provided on the U, V or W commutation signals.

2. Phase error for a servo type encoder is to detect that the incremental pulses have been counted incorrectly. The error is detected if the

incremental position moves by 10° with respect to the position defined by the UVW commutation signals. The trip is initiated if the error is

detected for 10 consecutive samples.

3. Phase error for SinCos encoders with comms is detected by interrogating the encoder every second via comms to compare the incremental

position determined from the sine waves with the incremental position via comms. If the error is greater than 10° for 10 consecutive samples the

trip is initiated. It should be noted that this system should not be used where 180 x Pr 5.11 (or Pr 21.11 for motor map 2) / Pr 3.34 is greater than

10° or else incorrect EnC3 trips will occur.

4. Incorrect encoder phasing is detected if the motor reaches half of the speed defined by SPEED_FREQ_MAX and the phasing error is larger

enough for the motor to accelerate uncontrollably. It can be disabled by setting Pr 3.08 to any value greater than zero.

5. This trip can also be caused when data is transferred between the encoder and a Solutions Module, such as an SM-Applications module, and an

error other than those covered by EnC5 or EnC6 occurs.

Encoders Reason for error Drive trip

All Power supply short circuit EnC1

Ab, Fd, Fr, Ab.Servo, Fd.Servo,

Fr.Servo,

SC, SC.Hiper, SC.EnDat, SC.SSI

+Hardware wire-break detect on A, B and Z inputs

(1)

Software wire break detection on sine wave signals

There is no wire break detection on the U, V and W commutation inputs

EnC2

Ab.Servo, Fd.Servo, Fr.Servo

SC.Hiper, SC.EnDat, SC.SSI

+Phase error

(2)

+Sine/cosine phase error

(3)

EnC3

SC.Hiper, SC.EnDat, SC.SSI

EnDat

SSI

Comms failure (timeout)

(5)

Comms failure (timeout) or transfer time too long

Comms transfer time is too long

EnC4

SC.Hiper, SC.EnDat, EnDat

Checksum/CRC error or SSI not ready at start of position transfer (i.e. data

input not one)

EnC5

SC.Hiper, SC.EnDat, EnDat

SSI, SC.SSI

The encoder has indicated an error

+Power supply failure

EnC6

SC, SC.Hiper, SC.EnDat,

SC.SSI, EnDat, SSI

Initialisation has failed due to a comms error. EnC7

SC.Hiper, SC.EnDat, EnDat

Auto-configuration has been requested by changing Pr 3.41, but an

initialisation has not occurred to perform auto-configuration.

EnC8

All

Speed feedback selected from an option slot that does not have a position

feedback category Solutions Module installed

EnC9

All

Incorrect encoder phasing

(4)

EnC10

SC, SC.Hiper, SC.EnDat, SC.SSI Failure of analog position alignment during encoder initialisation Enc11

SC.Hiper The encoder type could not be identified during auto-configuration Enc12

SC.EnDat, EnDat

The number of encoder turns read from the encoder during auto-

configuration is not a power of 2

Enc13

SC.EnDat, EnDat

The number of bits defining the encoder position within a turn read from the

encoder during auto-configuration is too large.

Enc14

SC.Hiper, SC.EnDat, EnDat

The number of periods per revolution is either less than 1 or greater than

50000 when read or calculated from the encoder data during auto-

configuration.

Enc15

SC.EnDat, EnDat The number of comms bits per period are larger than 255. Enc 16

SC.Hiper, SC.EnDat, EnDat

This is a rotary encoder (Pr 3.39=1 or 2) and the lines per revolution read

from this encoder are not a power of two.

Enc 17

Loading...

Loading...