Parameter

structure

Keypad and

display

Parameter x.00

Parameter

description format

Advanced parameter

descriptions

Serial comms

protocol

Electronic

nameplate

Performance

Menu 4

Digitax ST Advanced User Guide 73

Issue Number: 1 www.controltechniques.com

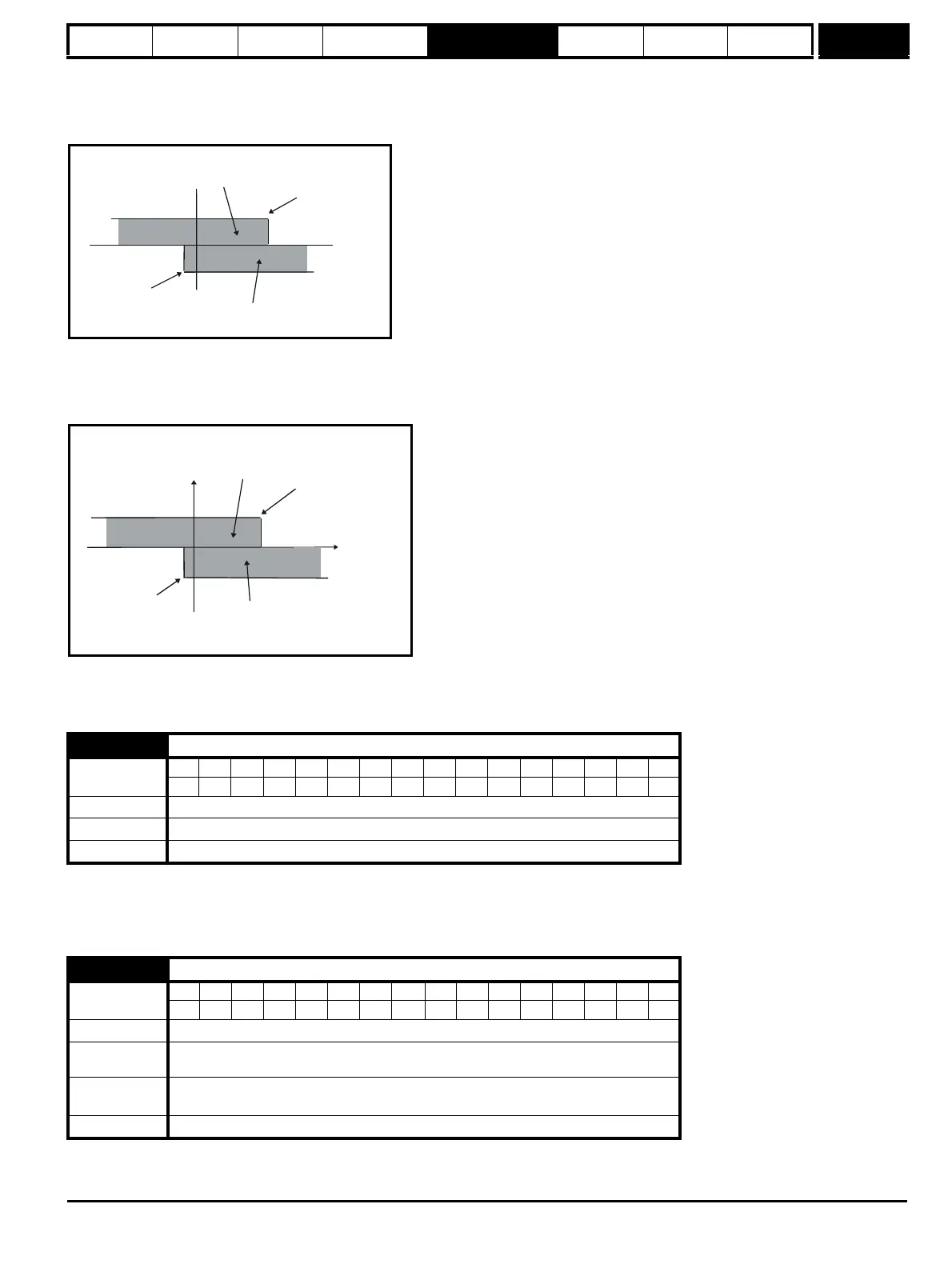

Example of coiler operation:

This is an example of a coiler operating in the positive direction. The final speed demand is set to a positive value just above the coiler reference

speed. If the resultant torque demand is positive the coiler operates with a limited speed, so that if the material breaks the speed does not exceed a

level just above the reference. It is also possible to decelerate the coiler with a negative resultant torque demand. The coiler will decelerate down to -

5rpm until a stop is applied. The operating area is shown in the following diagram:

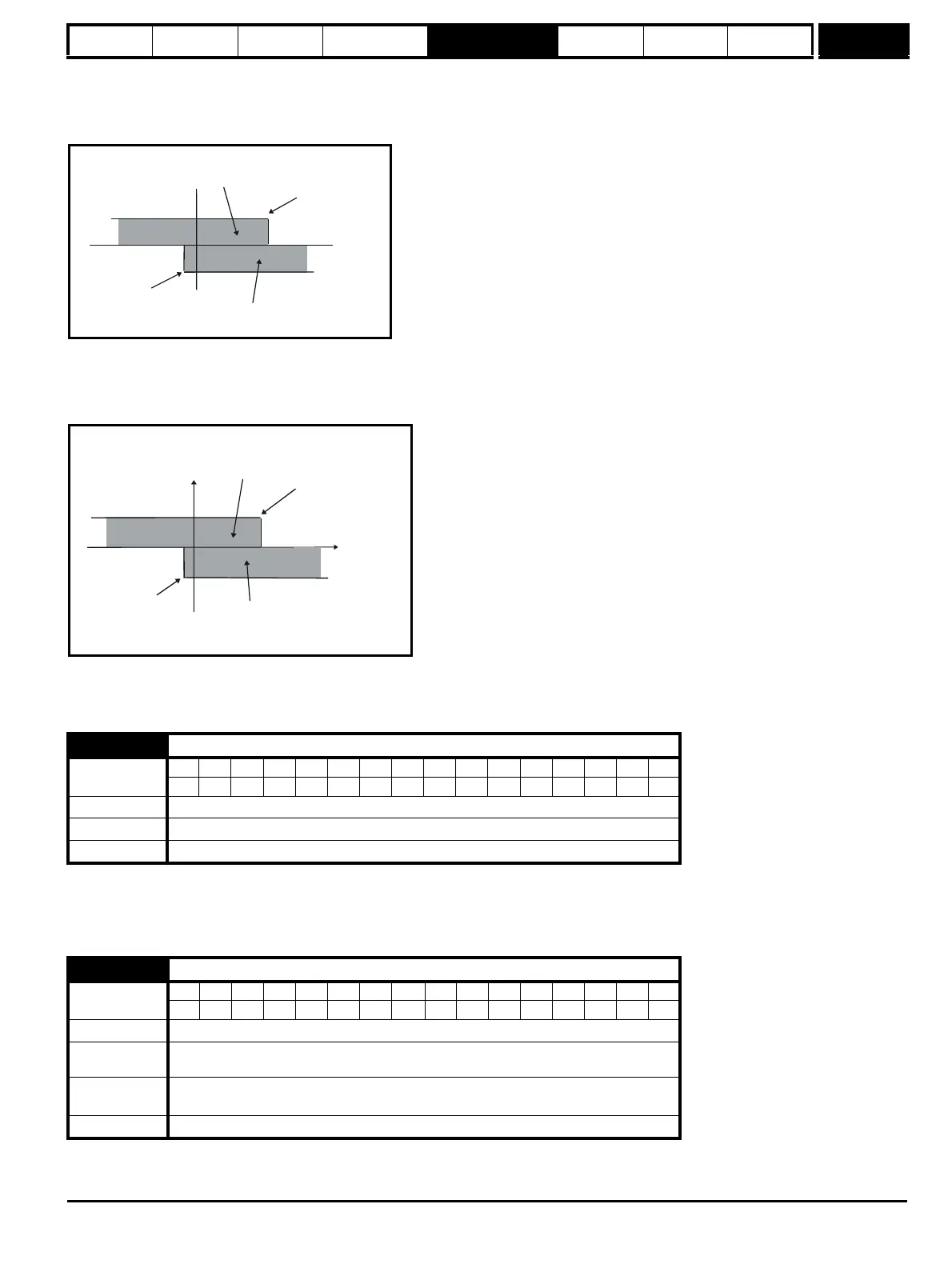

Example of uncoiler operation:

This is an example for an uncoiler operating in the positive direction. The final speed demand should be set to a level just above the maximum normal

speed. When the resultant torque demand is negative the uncoiler will apply tension and try and rotate at 5rpm in reverse, and so take up any slack.

The uncoiler can operate at any positive speed applying tension. If it is necessary to accelerate the uncoiler a positive resultant torque demand is

used. The speed will be limited to the final speed demand. The operating area is the same as that for the coiler and is shown below:

4: Speed control with torque feed-forward

The drive operates under speed control, but a torque value may be added to the output of the speed controller. This can be used to improve the

regulation of systems where the speed loop gains need to be low for stability.

A first order filter, with a time constant defined by this parameter, is provided on the current demand to reduce acoustic noise and vibration produced

as a result of position feedback quantisation noise. The filter introduces a lag in the speed loop, and so the speed loop gains may need to be reduced

to maintain stability as the filter time constant is increased. Alternative time constants can be selected depending on the value of the speed controller

gain selector (Pr 3.16). If Pr 3.16 = 0 Pr 4.12 is used, if Pr 3.16 = 1 Pr 4.23 is used.

4.12 Current demand filter 1

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

1 111

Range 0.0 to 25.0 ms

Default 0.0

Update rate Background read

4.13 Current controller Kp gain

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

111

Range 0 to 30,000

Default

200V drive: 75

400V drive: 150

Second motor

parameter

Pr 21.22

Update rate Background read

Final speed

demand

Area for coiler operation, speed

limited to ref and positve torque

Area for decelerating the coiler, reverse

speed limited and negative torque

-5rpm

Speed

Torque

-5rpm

Area for normal uncoiler

operation: negative torque,

limited to low speed in reverse

Speed reference

Area for accelerating

uncoiler: positive torque,

limited speed

Speed

Tor que

Loading...

Loading...