Parameter

structure

Keypad and

display

Parameter x.00

Parameter

description format

Advanced parameter

descriptions

Serial comms

protocol

Electronic

nameplate

Performance

Menu 5

Digitax ST Advanced User Guide 83

Issue Number: 1 www.controltechniques.com

• A test is performed to ensure that the feedback device direction is correct

•Pr 3.25 (phasing angle) is updated and saved to EEPROM.

This test will operate correctly when the load is an inertia, and although a small amount of cogging and stiction is acceptable, this test cannot be used

for a loaded motor. The test can only be used where the total inertia is less than 0.715 x T

rated

/ Pr 5.38 kgm

2

, assuming no additional stictional load,

where Trated is the torque produced by rated current as defined by Pr 5.07 or Pr 21.07. In most cases the motor only moves by the required angle,

however, it is possible for the test to initiate additional movement due to cogging torque. The amount of movement depends on the design of the

motor and is similar to the movement produced by cogging torque when the drive is disabled. If the motor is moving at a speed that is higher than the

zero speed threshold (Pr 3.05) when the test is initiated a tunE3 trip is initiated.

This test can be used with any type of encoder except a commutation only encoder i.e. Ab.Servo, Fd.Servo or Fr.Servo encoders with the lines per

rev set to zero. However, it is also not recommended with Ab.Servo, Fd.Servo or Fr.Servo encoders because the absolute position is not defined until

two valid changes of the commutation signals have occurred after power-up or an encoder trip. Therefore if the test is carried out before two valid

changes have occurred, the movement produced during the test may be quite large and the result may be slightly inaccurate. Once two valid changes

have occurred the test operates in the same way as for other encoder types.

The current controllers are used to perform this test, however, the default gains may be too high. It is not possible to carry out the necessary test to

set up the current controllers before the phasing angle is known. If the gains are too high the minimal movement phasing test may cause an OI.AC

trip. If this happens the current controller gains should be reduced progressively until the test is successful. Once the phasing angle is known, the

stationary test to set up the current controller gains only (Pr 5.12=4) may be used to obtain the correct gain values for the current controllers.

6. Current controller gain calculation only

• No current is applied to the motor.

• The current loop gains are calculated based on the value of the motor inductance (Pr 5.24) and resistance (Pr 5.17) and written to Pr 4.13 and

Pr 4.14.

•Pr 4.13 and Pr 4.14 are saved to EEPROM.

This is intended to be used as a method of setting up the current loop gains from user defined values of motor inductance and resistance. The drive

should not be enabled to perform these calculations. If the parameter is set to 6 it is automatically cleared by the drive once the calculation is

complete. It should be noted that the value changes back to zero within a few hundred milliseconds of being set to 6 by the user.

The auto-tune tests may be aborted by removing the run command or the enable or if a trip occurs. During the auto-tune tests the following trips can

occur in addition to the other drive trips.

*The rS trip is produced if the drive cannot achieve the necessary current levels to measure the stator resistance during the test (i.e. there is no motor

connected to the drive), or if the necessary current level can be achieved, but the calculated resistance exceeds the maximum values for the

particular drive size or it exceeds the maximum of Pr 5.17. The maximum measurable value for a particular drive size can be calculated from the

following formula.

Rs

max

= DC_VOLTAGE_MAX / Kc / 0.45 / √2

where Kc is the current scaling factor for the drive

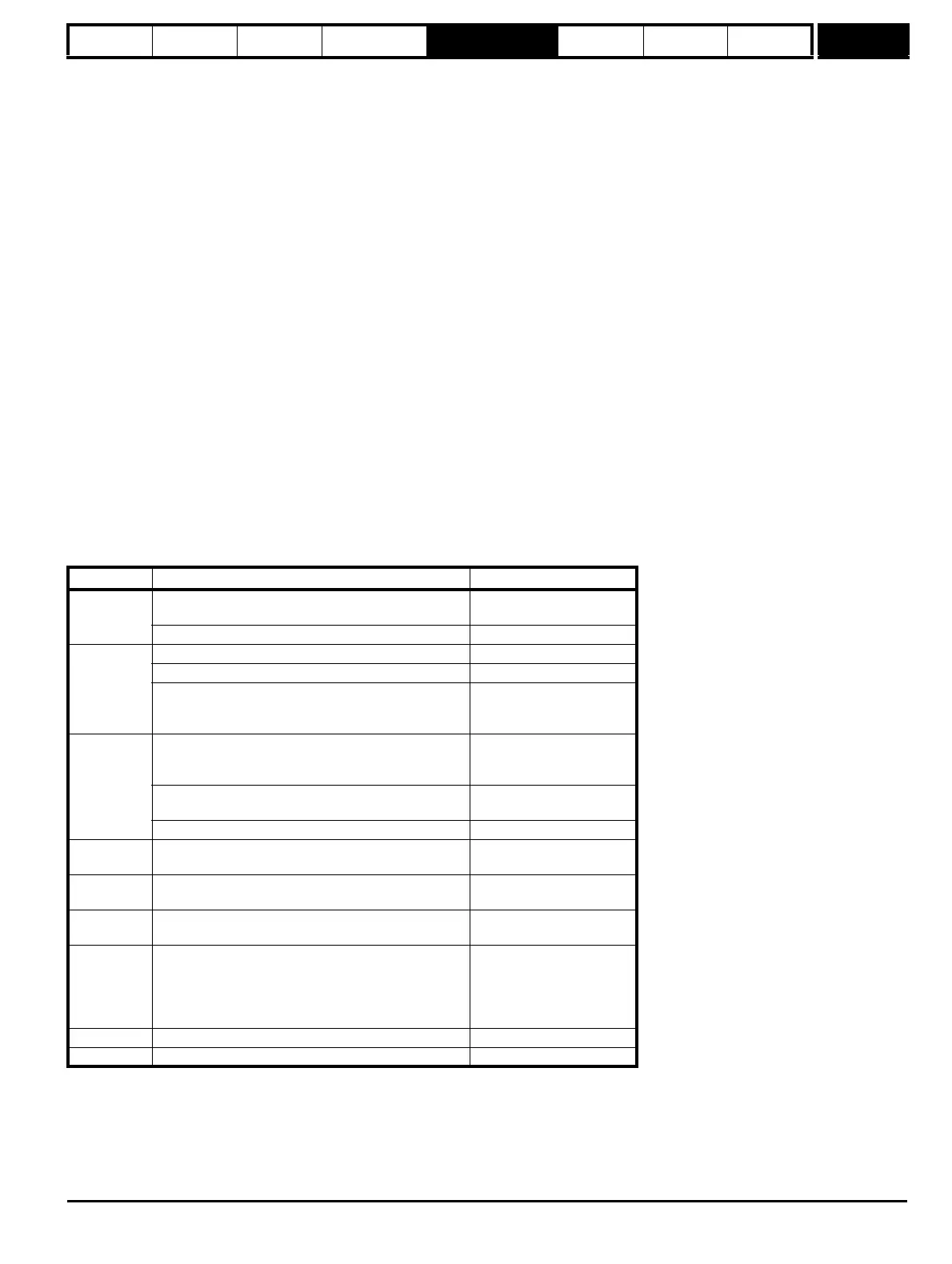

Trip code Reason Test which can cause trip

tunE1

The position feedback did not change

(i.e. motor did not turn or feedback failed)

1,2,5

The motor did not reach the required speed 3

tunE2

Position feedback direction incorrect 1,2

The motor could not be stopped 3

Minimal movement phasing test failed 5

tunE3

Drive encoder commutation signals connected

incorrectly, i.e. direction incorrect.

(Drive encoder only.)

1,2

The motor was moving when the minimal movement

phasing test was initiated

5

The calculated inertia is out of range 3

tunE4

Drive encoder U commutation signal fail

(Drive encoder only.)

1,2

tunE5

Drive encoder V commutation signal fail

(Drive encoder only.)

1,2

tunE6

Drive encoder W commutation signal fail

(Drive encoder only.)

1,2

tunE7

Motor poles or encoder lines set up incorrectly. A trip is

initiated if the speed is not within ±6.25% of the

expected no load speed just after the motor has

ramped up to speed. This trip will not occur if the motor

poles are set to more than 12.

1,2

tunE Auto-tune stopped before completion All

rS* Stator resistance too high 2

Loading...

Loading...