1

2

5

4

3

5

7

8

6

Note

alignment

marks

8

2

9

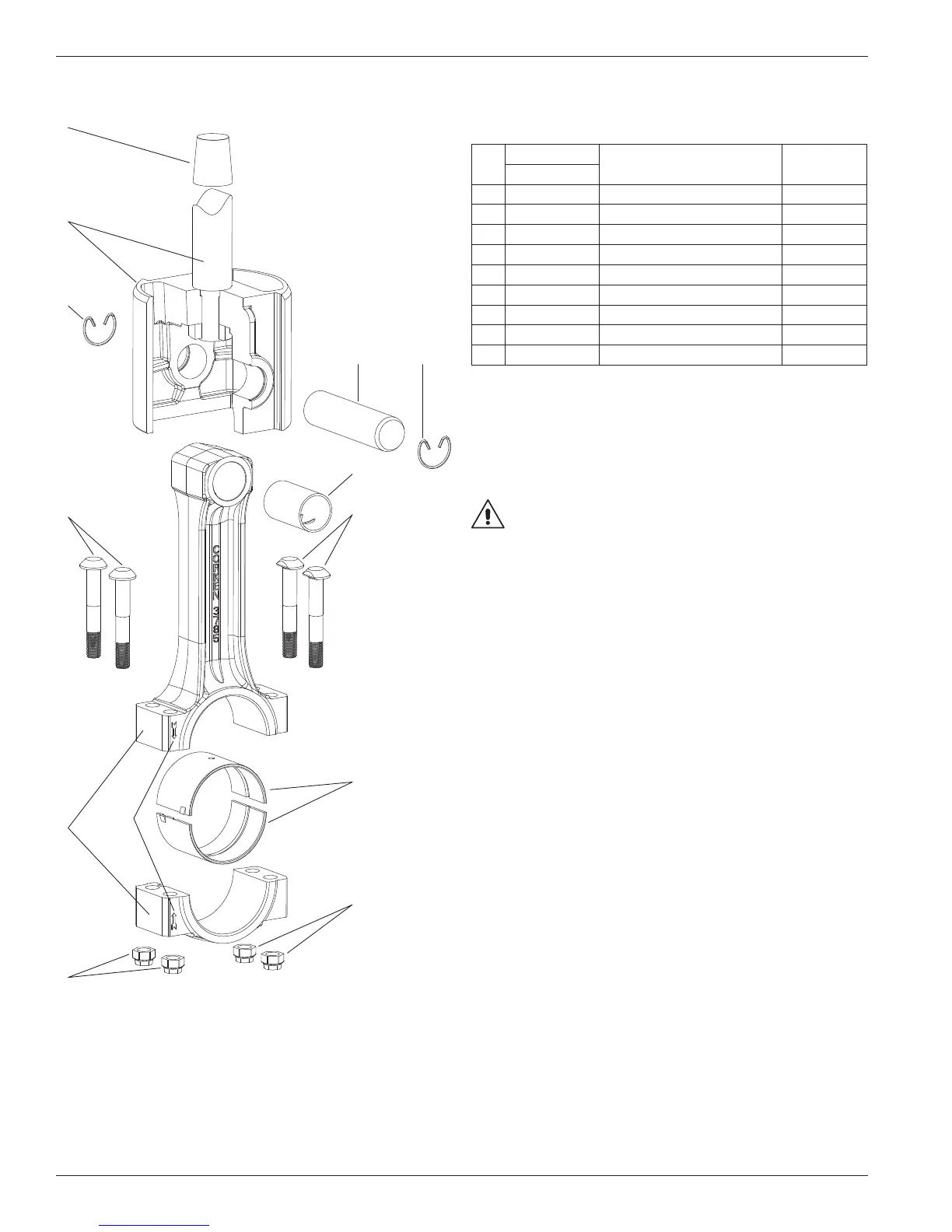

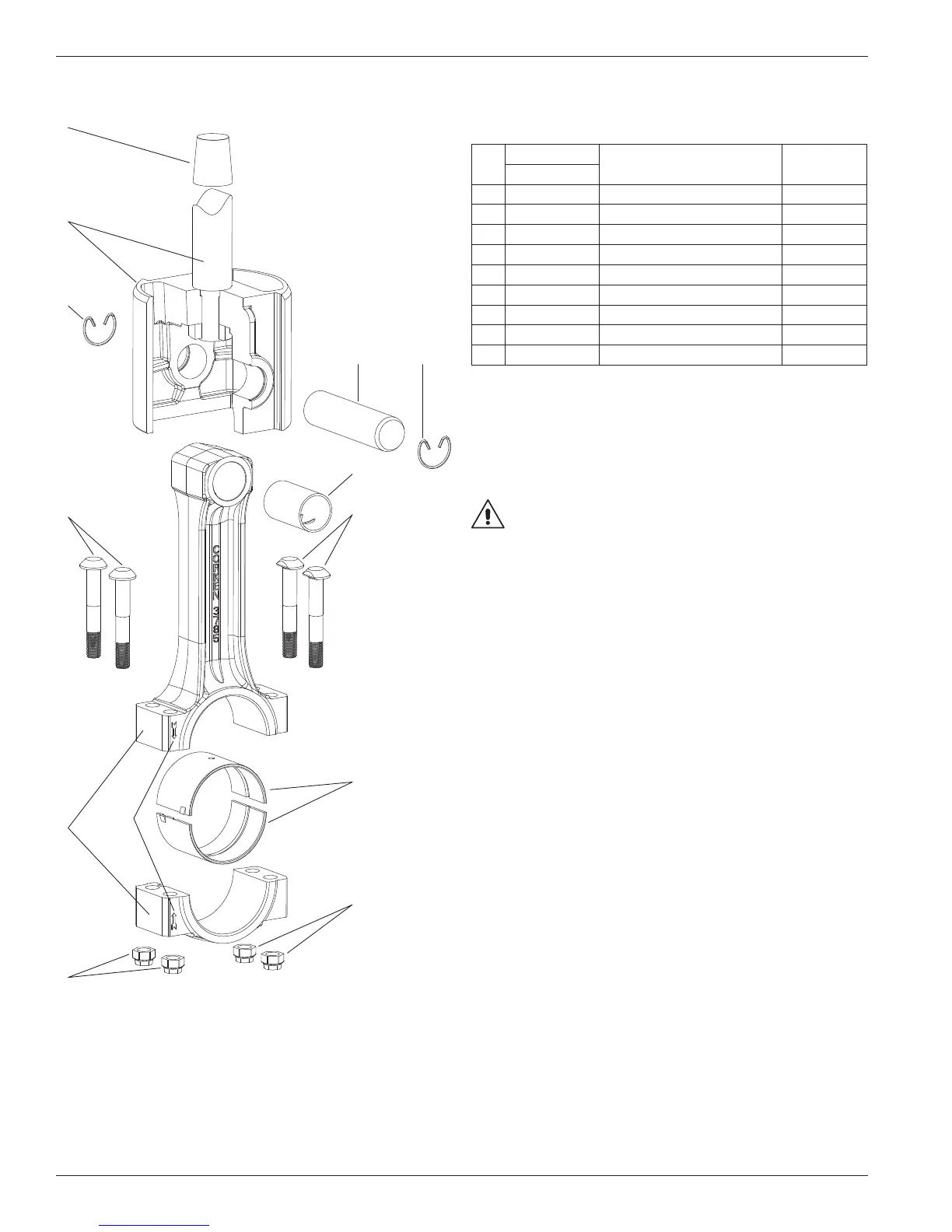

Appendix E—Parts Details for 691 and F691 Connecting Rod Assembly

Connecting Rod—Bill of Materials

Ref

No.

Part No.

Description

Qty. per

Compressor

Spec M Only

1. 3544-X4 Crosshead assembly 2

2. 3590 Retainer ring 4

3. 3540 Wrist pin 2

4. 3541-X

a, c

Wrist pin bushing 2

5. 1726

a

Bolt 8

6. 3785-X1 Connecting rod assembly 2

7. 3542

a

Connecting rod bearing (pair) 2

8. 1727

a, b

Nut 8

9. 4692 Packing installation cone 1

a

Included with connecting rod assembly

b

Torque connecting rod nut to 40 ft. lbs.

c

After the wrist pin bushing has been pressed into the connecting rod, it

must be honed to 1.1263/1.1259 (Spec M ONLY). A hydraulic press and

honing machine are recommended for this step.

Never attempt to separate the piston rod and crosshead. When repair

becomes necessary, the entire crosshead assembly must be replaced.

WARNING

CAUTION: Always relieve pressure in the unit before attempting

any repairs.

86

Loading...

Loading...