Maintenance

49

• Open the egine bonnet "A" (see fig. 41)

• Release the two tabs "1" "(see Fig. 42) on the right and left of the filter" B "

• Remove the cover "2"

• Remove the cartridge "3" and "4" from the filter compartment

• Thoroughly clean the cartridges "3" and "4"

• insert the cartridges "3" and "4" in the filter compartment "5"

• Close the cover "2" resuming the tabs "1"

To clean the print cartridge is advisable to blow air from the inside out .. after 5

times the cartridge must be changed, otherwise you could damage the engine.

CAUTION: Change of the cartridge after 12 cleaning each 8 Hours (change

each 96 hours)

4.3 HYDRAULIC CIRCUIT

4.3.1 Hydraulic Oil

OBLIGATION: Do not spill any oil and make the environment and the disposal

of the existing rules.

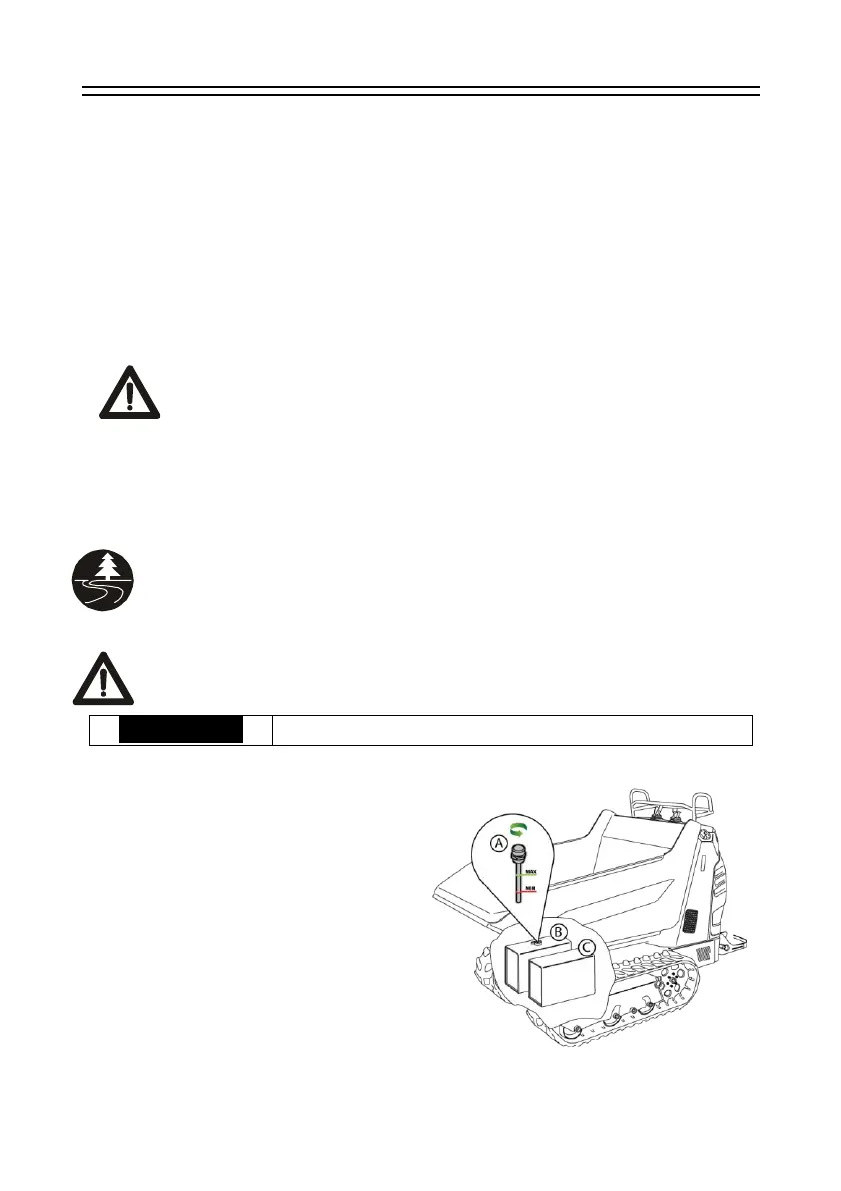

4.3.2 Verifying oil level

DANGER: The hydraulic oil can reach high temperatures, especially after a day

of work: avoid substituting the oil when it is hot to avoid the risk of burning

yourself.

Check the level of hydraulic oil in the tank

To verify the correct hydraulic oil

level, the machine will be placed

on a flat surface, with the body

closed and self-loading arm low-

ered to the ground, if any.

Il motore deve essere messo in moto

per alcuni minuti (circa 5 min.) in

modo chè l’olio abbia una tempera-

tura di 40°C.

Loading...

Loading...