Inconveniences and breakdowns

53

5 INCONVENIENCES AND BREAKDOWNS

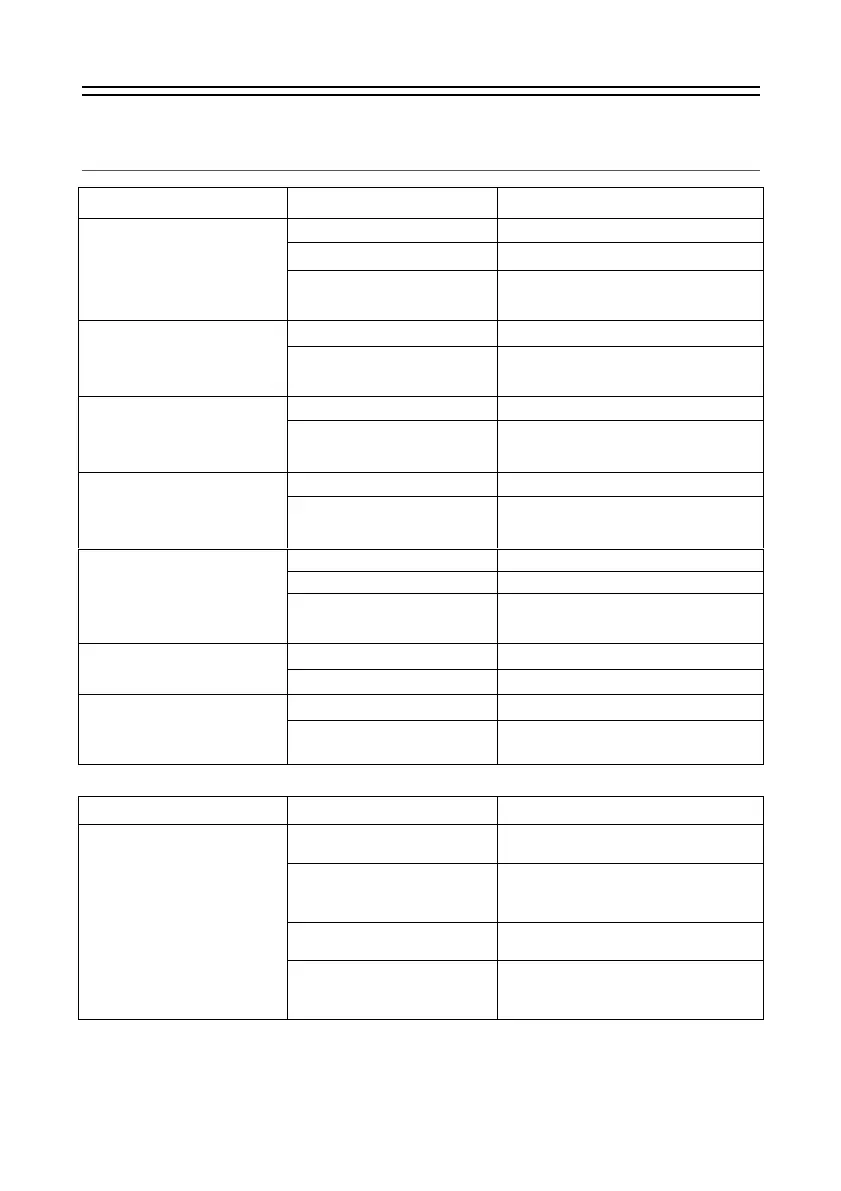

Hydraulic oil is leaking.

Turn off the machine and let it cool down

Breakdown in the hydraulic cir-

cuits.

Have the machine looked at by a mechan-

ic with specific competence

Breakdown in hydraulic circuits

or in washers.

Have the machine looked at by a mechan-

ic with specific competence

The hydraulic commands do not

respond correctly.

Refill to the correct level

Breakdown in the hydraulic cir-

cuits.

Have the machine looked at by a mechan-

ic with specific competence

The body or the arms of the

bucket moves slowly.

Interrupt work and let it cool down

The motor does not have power.

Have the machine looked at by a mechan-

ic with specific competence

Lack of pressure in the auxiliary

hydraulic openings.

Refill to the correct level

Sleeves not correctly inserted.

Insert the sleeves correctly

Breakdown in the hydraulic cir-

cuits.

Have the machine looked at by a mechan-

ic with specific competence

Eccessive oil temperature.

Refill to the correct level

Interrupt work and let cool down

Parking brake does not deacti-

vate.

The brake cable is broken.

Have the cable substituted by a mechanic

Move the machine slightly forward and

backward and try again

The machine does not move.

The parking brake is activated.

Deactivate the parking brake

Not enough oil in the hydraulic

circuit.

Restore oil to the correct level

Breakdown in the hydraulic

components.

Have the machine looked at by a mechan-

ic with specific competence

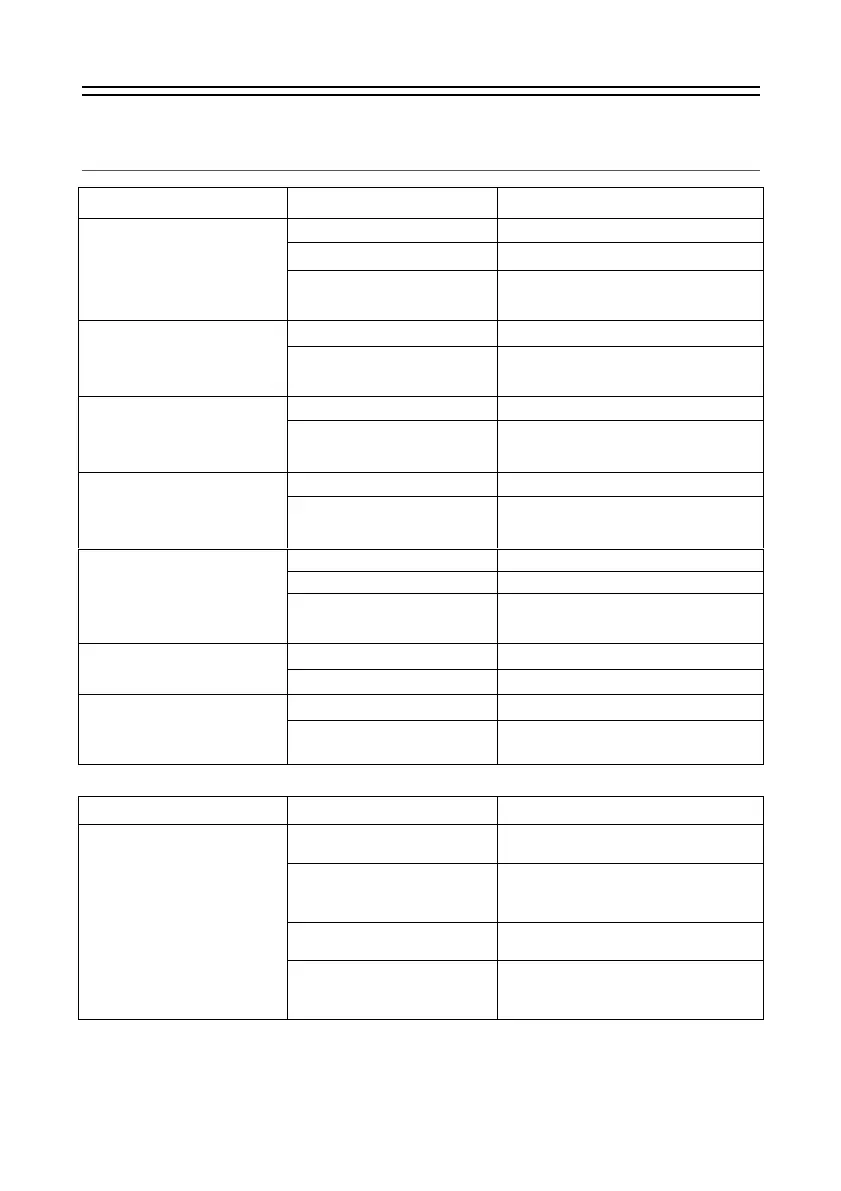

Loading...

Loading...