Maintenance

Cornelius Deutschland GmbH

Document no. TD2005100

Version 15/03/2019, Index 0

Installation and service manual Dispensing valve

SFV1

12

5 Maintenance

DANGER!

Risk of personal injury and equipment damage due to non-compliance with safety information!

If you fail to observe the safety information, you risk creating operating conditions at the dispensing valve which

may cause personal injury or damage to equipment.

• Please always strictly observe all safety measures and information/instructions, see chapter 1.

NOTICE!

All installation, maintenance and repair work on the dispensing valve must be carried out by an expert only.

WARNING!

Risk of personal injury and equipment damage due to operation by non-qualified staff!

It is dangerous for non-qualified staff to operate the unit!

• Service operations on the dispensing valve may only be carried out by trained and certified experts who

have been trained in undertaking service operations on the dispensing valve.

• All wiring and plumbing must be carried out in compliance with national and local laws, regulations and

guidelines. Non-compliance with these laws, regulations and guidelines may result in death, serious injury

or equipment damage.

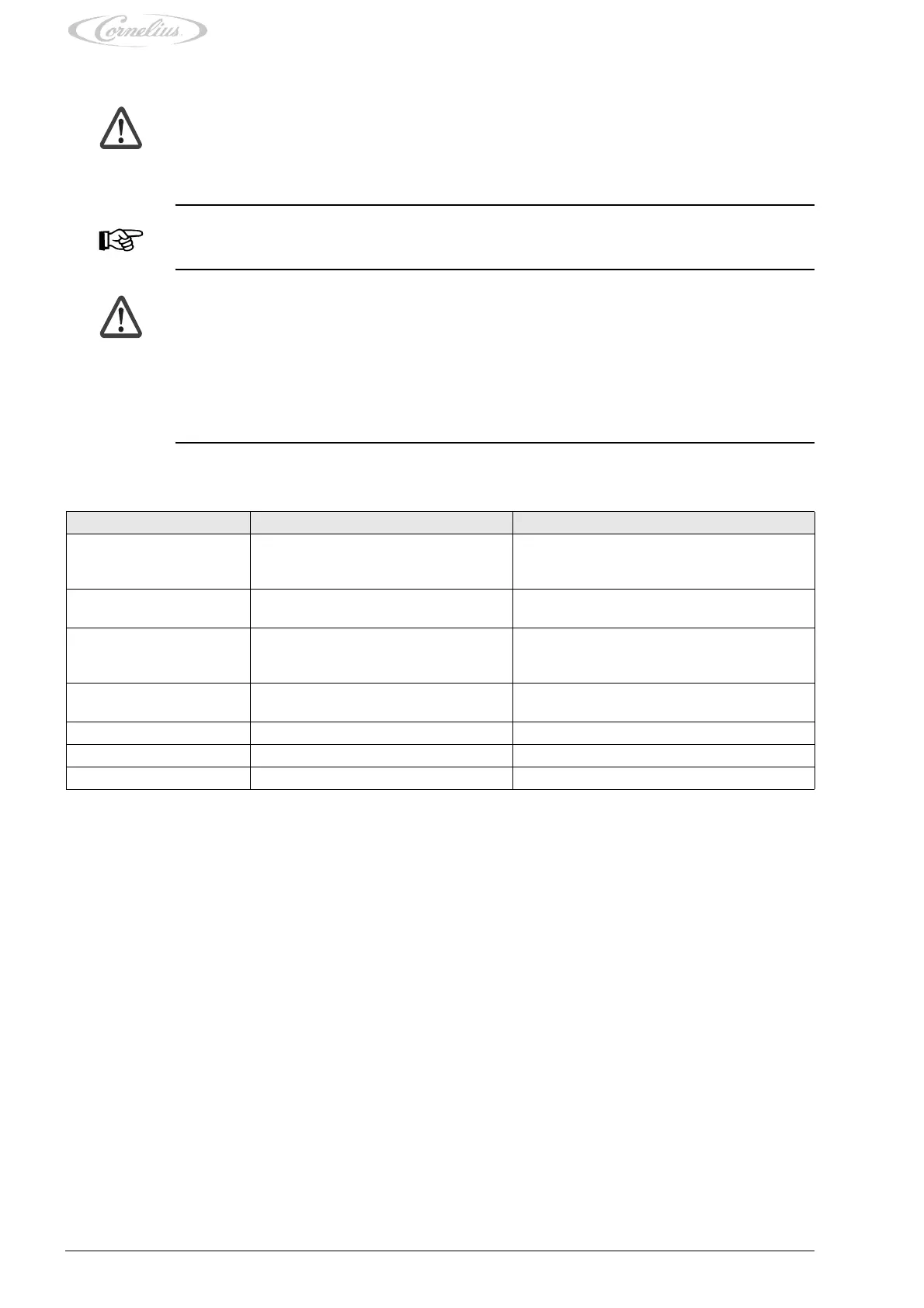

5.1 Maintenance table

Interval Components Action

Daily Dispensing valve, exterior Carry out a visual inspection, see the document

“Dispensing valve operator manual”, document

no.: TD2005000

Daily Dispensing valve, exterior Clean, see the document “Dispensing valve oper-

ator manual”, document no.: TD2005000

Daily Dispensing nozzle Carry out a visual inspection, see the document

“Dispensing valve operator manual”, document

no.: TD2005000

Weekly Dispensing nozzle Clean, see the document “Dispensing valve oper-

ator manual”, document no.: TD2005000

Every 3 months Diffusor seal Perform a visual inspection; see chapter 5.2

Every 3 months Baffle seal Perform a visual inspection; see chapter 5.2

Every 3 months Dispensing valve, interior Clean the valves; see chapter 5.3

Loading...

Loading...