Viper Low overrun Service Manual

Publication Number: 621360241LOEWSE - 44 - © 2016, Cornelius Inc.

COMPONENT REPLACEMENT

The following are procedures for servicing the major components of the Viper system.

BARREL MOTOR SEAL REPLACEMENT

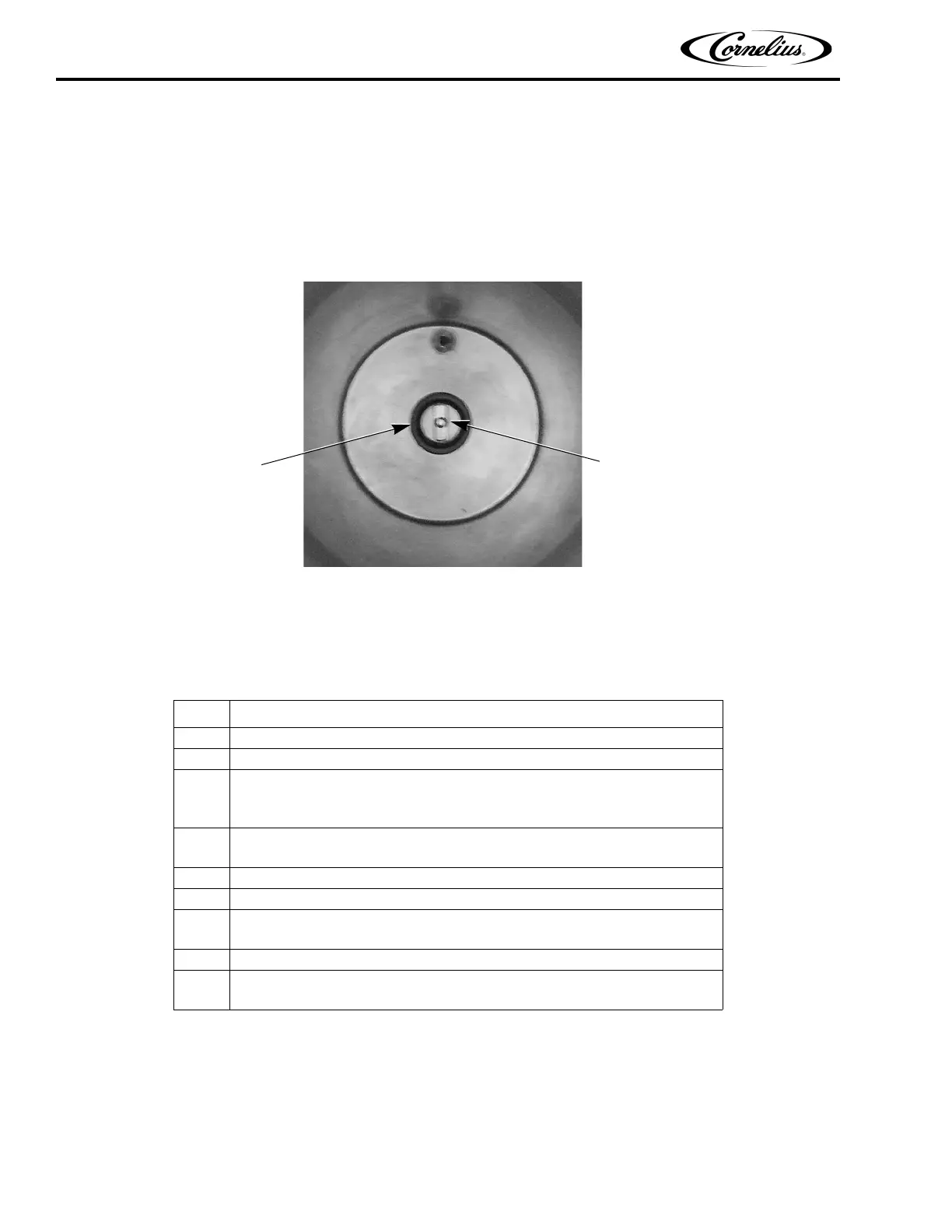

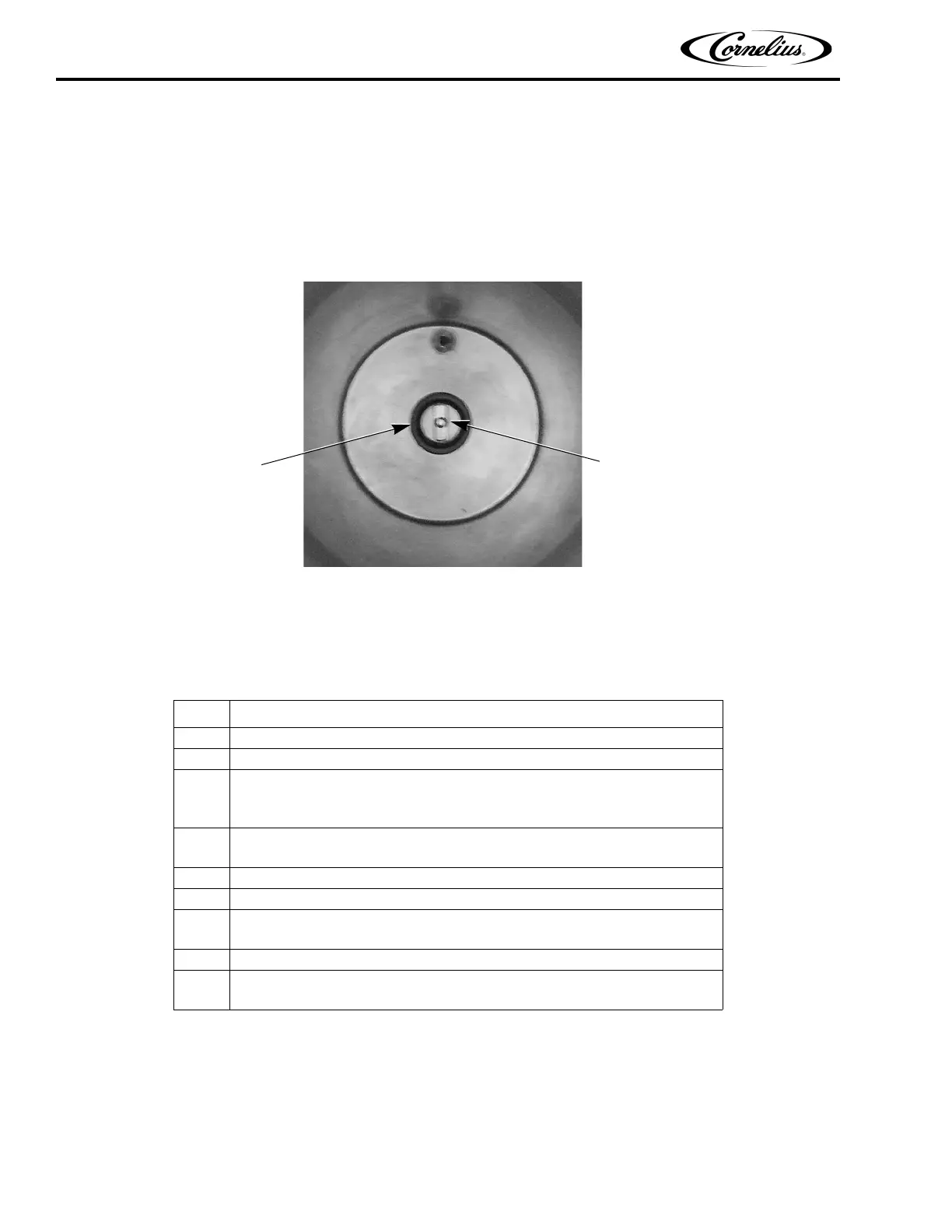

The barrel motor seal is typically replaced during the semi-annual preventative maintenance procedure. The seal

location is shown in Figure 34.

Figure 34. Front View Inside of Barrel w/ Faceplate Removed

REMOVING THE EXISTING SEAL

To remove the existing barrel seal, perform the procedure in Table 45.

INSTALLING A NEW SEAL

Perform the procedure in Table 46, Figure 35 and Figure 36 to replace the barrel seal with a new seal. When install-

ing a new seal, NEVER use oil or silicon based lubricants. This can cause the new seal to rotate and LEAK!

Table 45.

Step Action

1. Purge the barrel. See “Purging a Barrel” on page 25.

2 When purging is complete, disconnect power from the unit.

3

Open the relief valve on the front of the barrel to ensure that pressure is

released. CAUTION: Barrel pressure MUST be relieved before removing the

faceplate!

4

Remove the four (4) 3/4 in. nuts from the faceplate and slowly remove the face-

plate from the unit.

5 Carefully pull the blade assembly out of the barrel.

6 Remove any remaining product from the barrel.

7

Rinse and inspect the blade assembly and barrel for signs of wear (Replace if

necessary).

8 Remove the seal and spacer from the rear of barrel.

9

When old seal and spacer are removed, use a clean soft cloth to clean

between the motor shaft and the barrel to remove any remaining product.

Loading...

Loading...