16 • Checkit Refrigeration System Monitor (P/N 508-2000) 026-1701 Rev 0 01-05-98

Installation Procedure

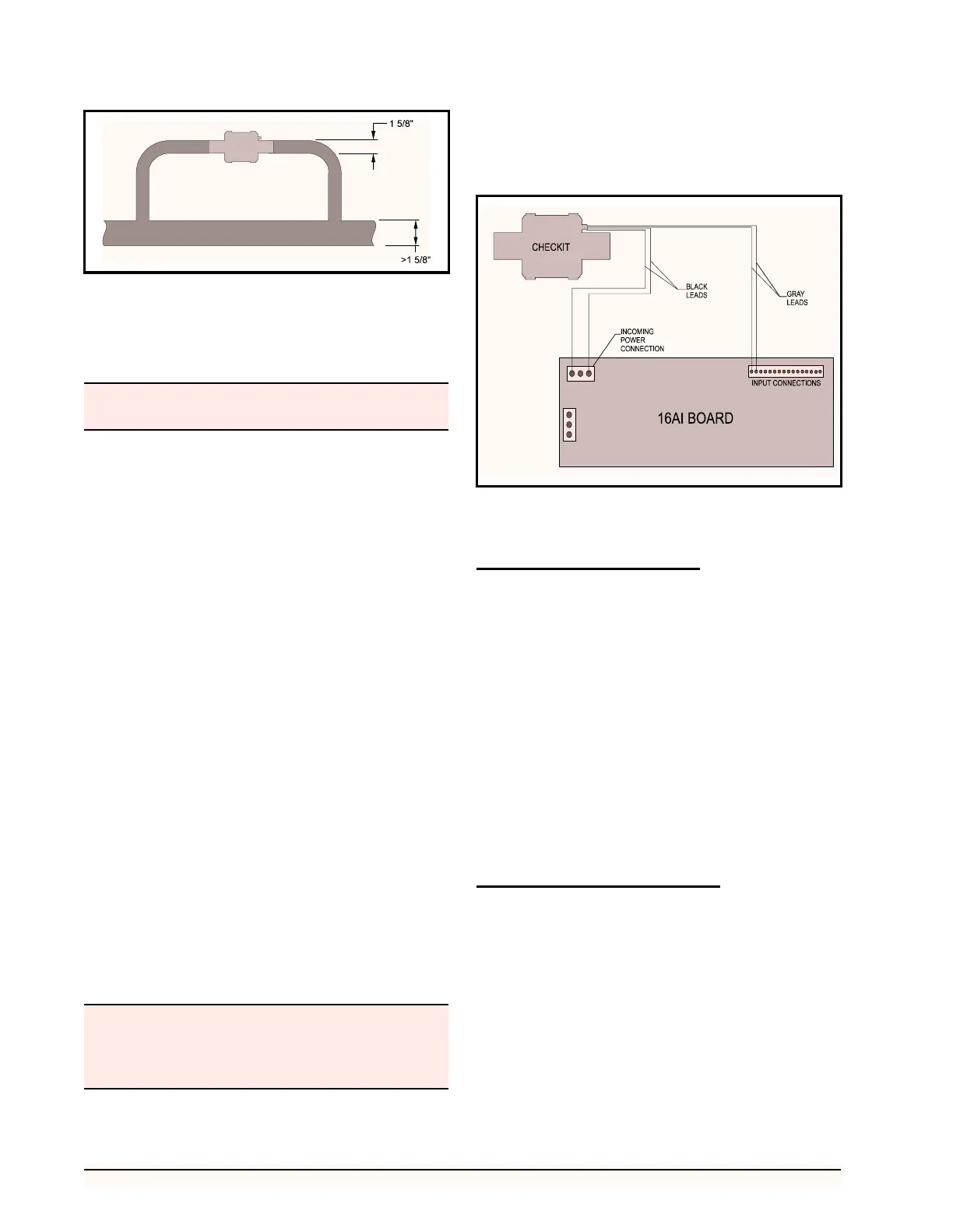

1. Remove the sensor from the holding tube on

the vessel.

2. Solder the vessel directly into the refrigera-

tion line, or on a bypass line if the main line

is larger than 1-5/8".

3. After the vessel and refrigeration line have

cooled completely, apply Wakefield Thermal

Joint Compound #120-5 (CPC P/N 020-

7120) or equivalent on the sensor and re-in-

sert the sensor into the holding tube. (If nec-

essary, silicone sealer may be applied to the

end of the sensor after installation to help en-

sure the sensor remains in the holding tube.)

When installed, the sensor should fit com-

pletely within the holding tube.

4. Secure the sensor leads to the refrigeration

line with a standard cable tie located adjacent

to the sensor.

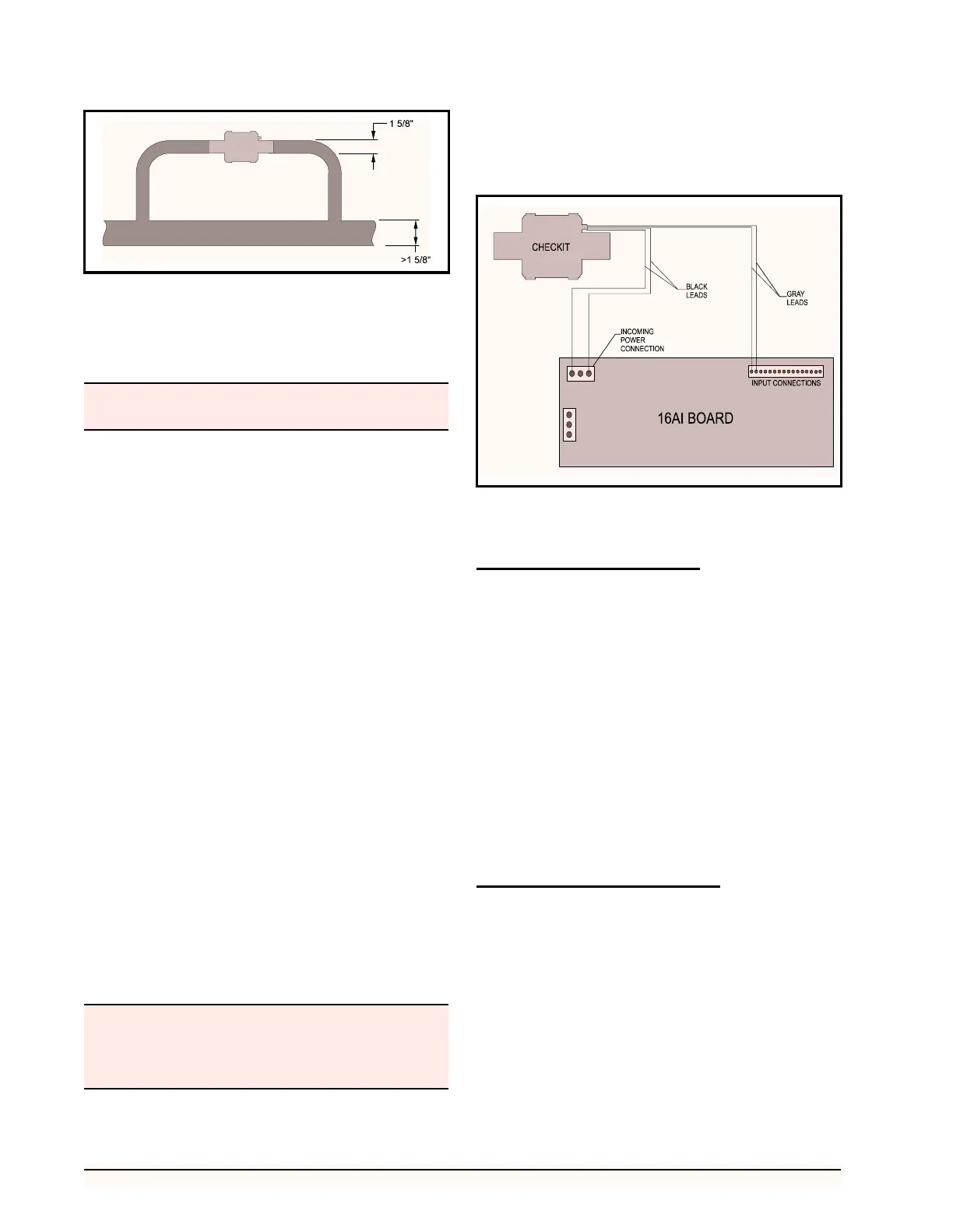

5. The Checkit sensor requires 24 VAC. Con-

nect the sensor leads as follows: (a)Connect

the two black leads to the 24 VAC output on

the 16AI board, as shown in Figure 14, or to

an alternate 24 Volt power source. (b)Con-

nect the two gray leads to an input on the

16AI board (the polarity of each of the leads

is not important). Set the corresponding in-

put’s dip switch to the UP position.

6. Checkit installation is complete.

If a damaged Checkit sensor needs to be replaced, fol-

low the instructions above, skipping Step 2, using a re-

placement sensor (CPC P/N 201-2010).

Set-up

Board and Point Settings

Before monitoring of the Checkit sensor by the RMCC

can begin, the location of the Checkit sensor must be iden-

tified. The following procedure should be used for location

identification:

1. Return to the Main Menu.

2. Select 7) Configuration from the Main Menu.

3. Select 1) Input Definition from the Configu-

ration Menu.

4. Page down the Input Definitions Pages to the

Checkit Page.

5. Input the 16AI board number and point num-

ber for the Checkit sensor.

6. Checkit sensor setup is complete.

Set Points and Time Delays

To configure the RMCC unit for Checkit monitoring,

the following procedure should be followed:

1. Log on the RMCC unit with the proper pass-

word.

2. Select 1) Pressure Control from the Main

Menu.

3. Select 3) Alarms from the Pressure Control

Menu.

4. Page down the Alarms Pages to the Checkit

Page.

Figure 13 - Installation of Checkit and Bypass for Lines Larger

than 1 5/8”

The Checkit sensor assembly may become hot during

the soldering process.

Power to the sensor should be shut-off and the sensor

allowed to cool completely if it becomes necessary to

remove the sensor from the holding tube for inspec-

tion or replacement.

Figure 14 - Checkit Typical Power Connections

Loading...

Loading...