28 • Refrigerant Transducer (P/N 809-1550) 026-1701 Rev 0 01-05-98

tion. However, it is likely that multiple RTs will be in-

stalled and, therefore, an additional power supply must be

provided. Because RTs draw high current during power up,

a power supply with delayed foldback current limiting is

required. Delayed foldback current limiting prevents cur-

rent limiting long enough for the power supply to reach 12

volts. If more than one transducer per 16AI board is to be

installed, connect the RTs to CPC Power Supply (P/N 258-

1000).

Location

The RT is designed to monitor an area of 1000 cubic

feet, and should be mounted to allow the leak sensor to de-

tect a refrigerant leak quickly. Consideration should be giv-

en to air flow patterns, proximity to doorways, and

interference that could limit the ability of the transducer to

sense a refrigeration leak. Since refrigerant is heavier than

air, the lower the location of the RT, the more quickly the

RT will detect a refrigerant leak.

Non-Refrigerant Gas Detection

The refrigerant transducer uses a metal oxide coated re-

sistor for detecting refrigerants. Although highly sensitive

to CFCs and HCFCs, the sensor will also detect other gases

present in the sensing area. By programming alarm and no-

tice delay set points within the CPC controller, detection of

these gases can be filtered to ensure only CFC or HCFC de-

tection causes alarm or notice conditions. Some of the gas-

es that will be detected by the RT are listed below:

• Methyl Chloride

• Methylene Chloride

• Chloroform

• Carbon Tetrachloride

• Ethyl Chloride

• Ethylene Chloride

• Trichlorothane

• Tetrachloroethyelane

• Chlorobenzene

• Ethanol

• Octane

• Hexane

• Carbon Monoxide

•Isobutane

• Carbon Dioxide

Mounting

The RT is 3.2 inches wide, 2.1 inches high, and 1.6

inches deep.

1. Loosen the cover set screw on both sides of

the protective cover, and remove the cover.

2. Loosen the two board mount screws, and re-

move the board from the mount plate.

3. Secure the mount plate using four screws.

4. Remount the board using the two mount

screws.

5. After wiring, replace the protective cover and

set screws.

System Connections

A total of 16 refrigeration transducers may be installed

on one 16AI board. This limitation is due to the total num-

ber of input terminals on the board. In addition, no more

than 16 RTs may be connected to one external power sup-

ply. Regardless of the number of sensors connected to the

input terminal of the 16AI, only one RT may be connected

to the power output connection of the board. The following

layouts should be used when installing single or multiple

RTs.

The RT and the 16AI board do not need to be located

close to each other. Table 7 lists the maximum cable

lengths and required cables for RT connection to the 16AI

board.

Single Refrigerant Transducer Layout

Connect the refrigerant transducer to the 16AI input

board as shown in Figure?.

1. Attach the black wire to the -V terminal of the

RT and attach the green wire to the 0V termi-

nal of the RT.

2. Tie the back and green wires together at an

odd terminal of the 16AI input connection.

3. Attach the white wire to the OUT terminal of

the RT and an even terminal of the 16AI

board input connection.

4. Attach the red wire to the +V terminal of the

RT and a 12V terminal on the 16AI power

output connection.

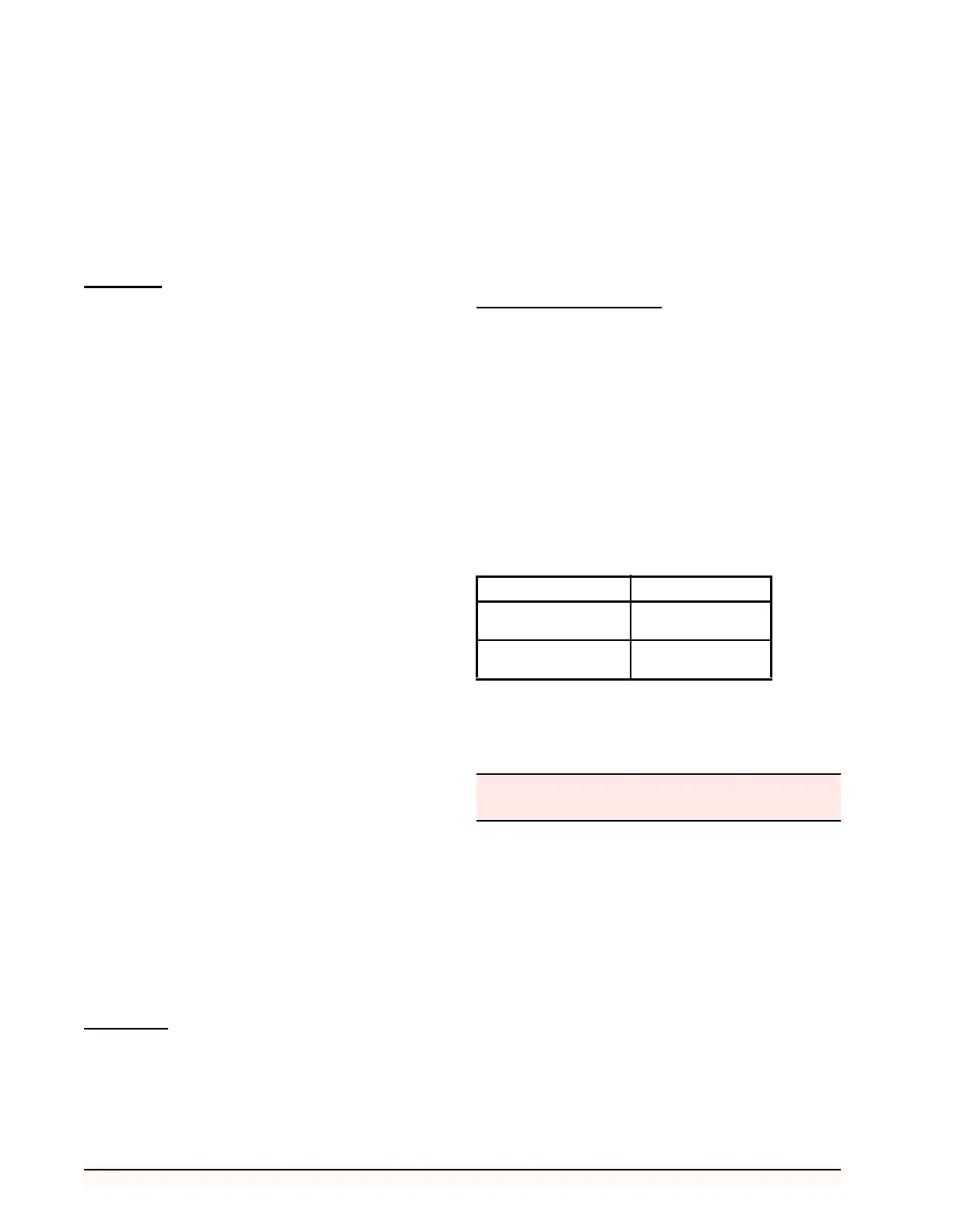

Max Cable Length Cable Type

700 Belden #8729

(22AWG or equiv.)

1800 Belden #9418

(18AWG or equiv.)

Table 7 - RT Connection Cable Lengths

Do not jumper the -V and 0V terminals of the refrig-

erant transducer.

Loading...

Loading...