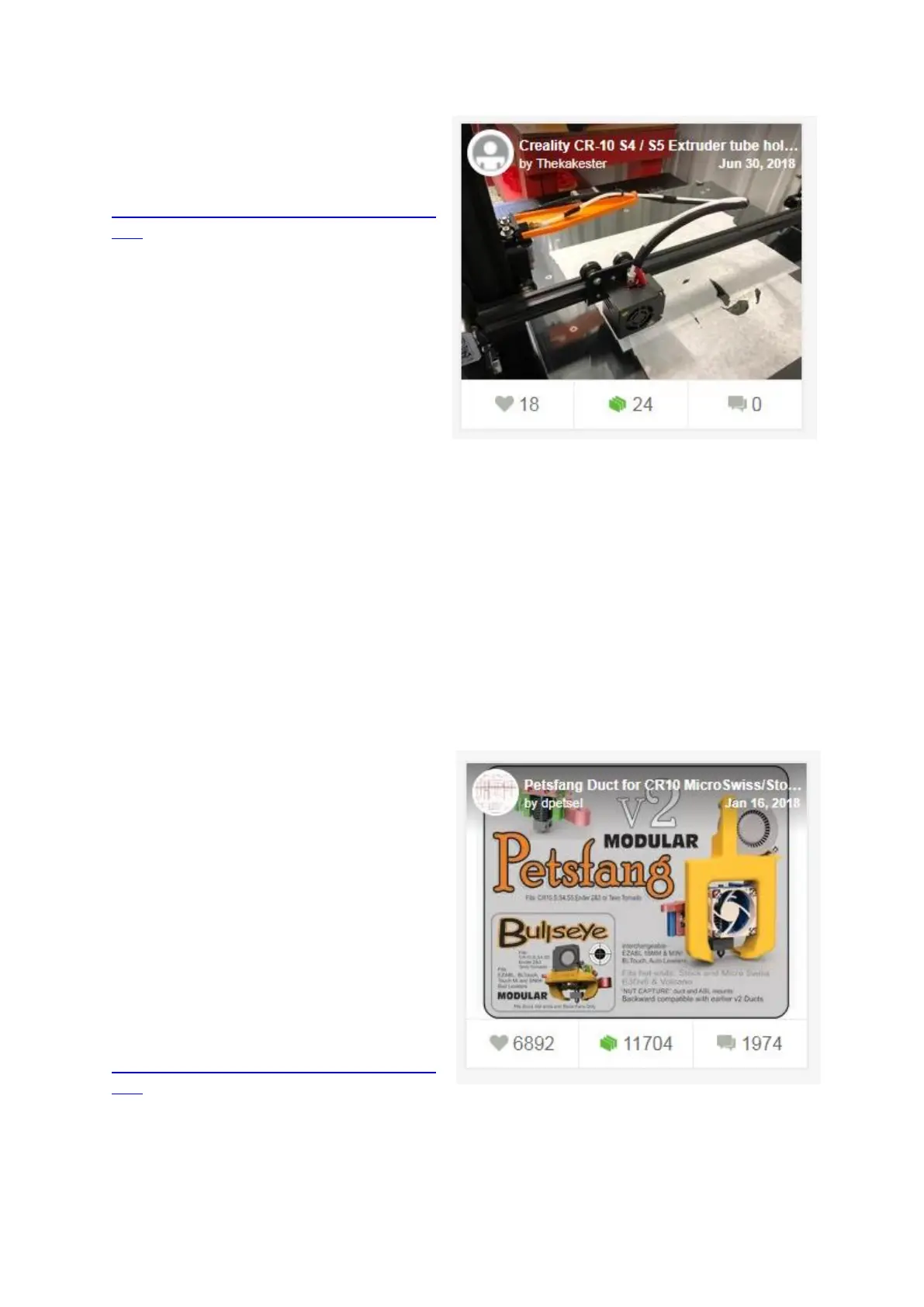

Here is another design for better

managing the bowden tube:

https://www.thingiverse.com/thing:2984

407

The author has used this holder for the

bowden tube and kept the cable

attached to the tube.

All solutions are fine, as long as the

cable and tube do not touch the parts

being printed during the print

operations.

If you plan to upgrade to dual extrusion later, or change the stock extruder for a

stronger dual-drive extruder (which is a good idea at some point and is documented

later in this document), then the first design will still work but not the second, as it is

only working with the stock extruder.

Optional – Install ventilation fangs on your hotend

Recap so far: You have a brand new printer, with good enough bed levelling,

stiffening braces, motor dampeners and possibly bed feet, side filament and control

box holders, and you are keen on printing more difficult stuff.

Here is your first big move forward.

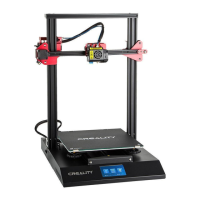

I have marked this upgrade “optional”,

because I believe that many prints can

be achieved with good enough quality

with the stock print head. However, no

denying that many many users of CR-

10 printers upgrade their head with

“fangs”.

To cut it short, there are many designs

available online and I chose the one

that I found the most modular and

popular, the “modular petsfang v2”

here:

https://www.thingiverse.com/thing:2759

439

There are advantages with this design, like the probe holders available for bed

levelling probes on the left or right hand side of the hotend. And as the next step will

Loading...

Loading...