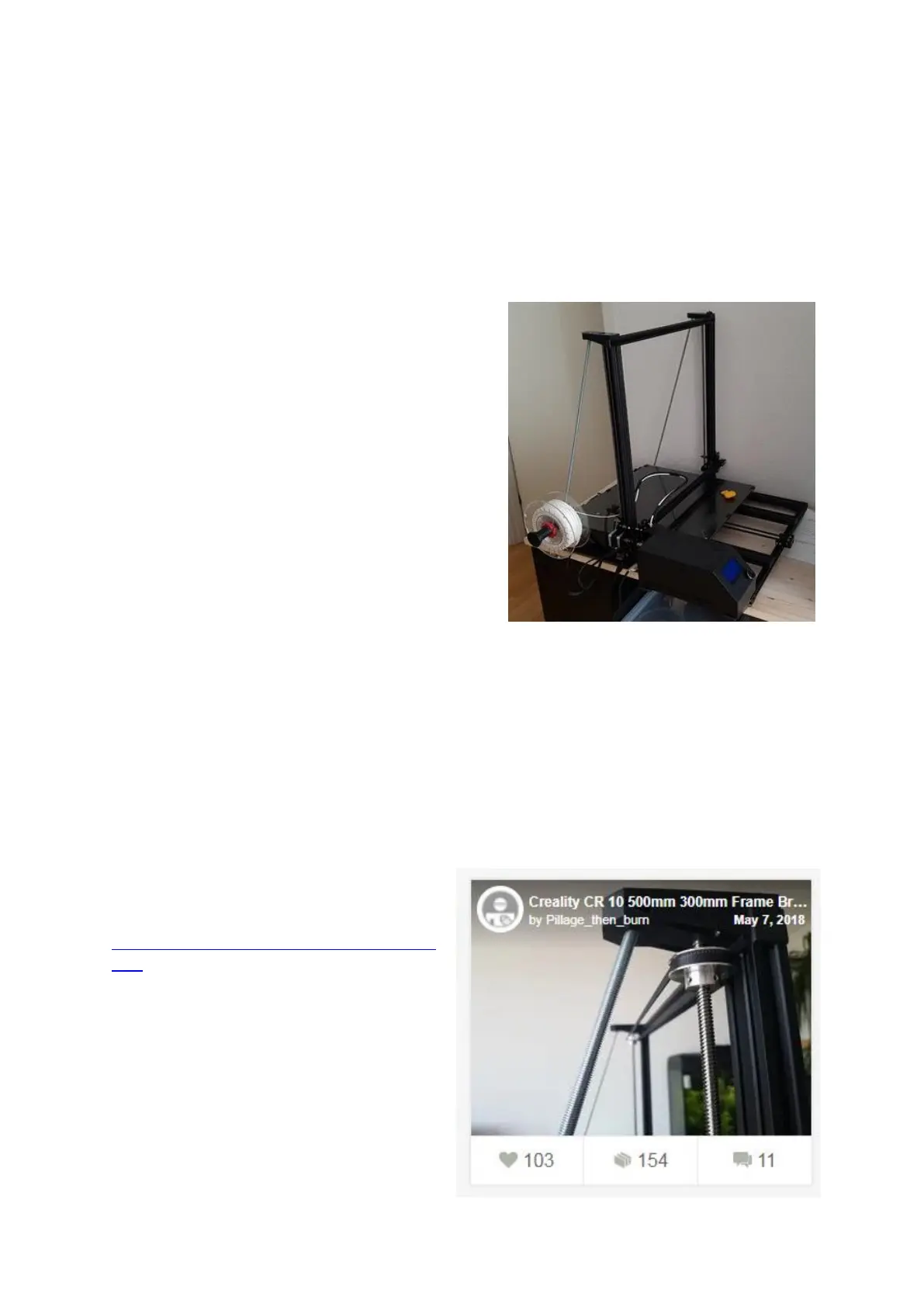

Highly recommended - Strengthening the frame

Now that the levelling knobs have been replaced with locking ones, you can start

printing bigger parts, and for longer print times. However, as soon as the height of

the printed parts is above a few centimetres, you will start noticing vibrations of the

vertical bars of the frame. A classic remediation of this is to add braces.

Every owner of S5 printer seems to have to do that at some point, so do it now!

OPTIONS: At this stage, you have again 2

options:

1/ purchase a brace kit from Creality. I

understand it involves piercing holes in the

frame of the printer, and all accessories are

included for that operation;

2/ make your own braces out of threaded rods

and printed parts.

I went for the second option and had to decide

between 2 sub-options:

2.a/ install the braces in front of the printer;

2.b/ install the braces on the back of the printer.

I chose the second option for several reasons:

a) placing braces on the back frees up the front of the printer for object

manipulation;

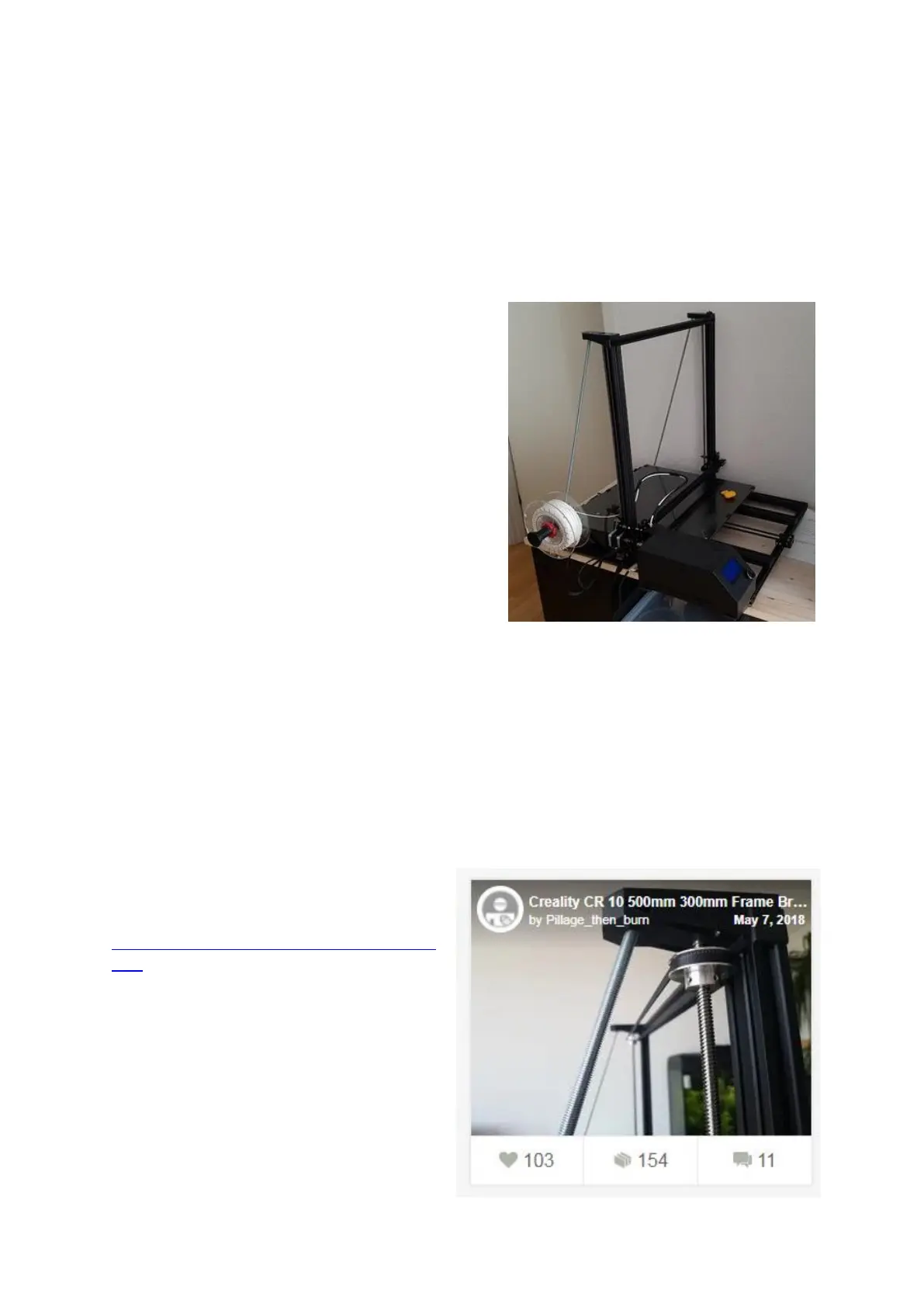

b) I found a neat design online that included additional features like a side holder

for filament (see photo);

c) this fits well the area where I placed my printer ultimately.

Especially for the third reason I went for

this design:

https://www.thingiverse.com/thing:2898

173

When parts are printed, you need the

following hardware to complete the

setup:

x2 1 meter M8 threaded rods

x4 M8 nuts

stock + extra M4 bolts

M4 T-slot nuts

(refer to website for details)

Loading...

Loading...