forward improving your printer and slowly discover its capabilities, just skip this and

move to the next step.

If you want to know what manual mesh levelling is about, please read the

documentation on this topic, starting from there:

http://marlinfw.org/docs/gcode/G029-mbl.html

I personally recommend keeping printing on a small area in the front left corner of

this printer for the time being, with the already improved bed levelling knob, and wait

for a few more steps before getting to larger prints. Walk before run.

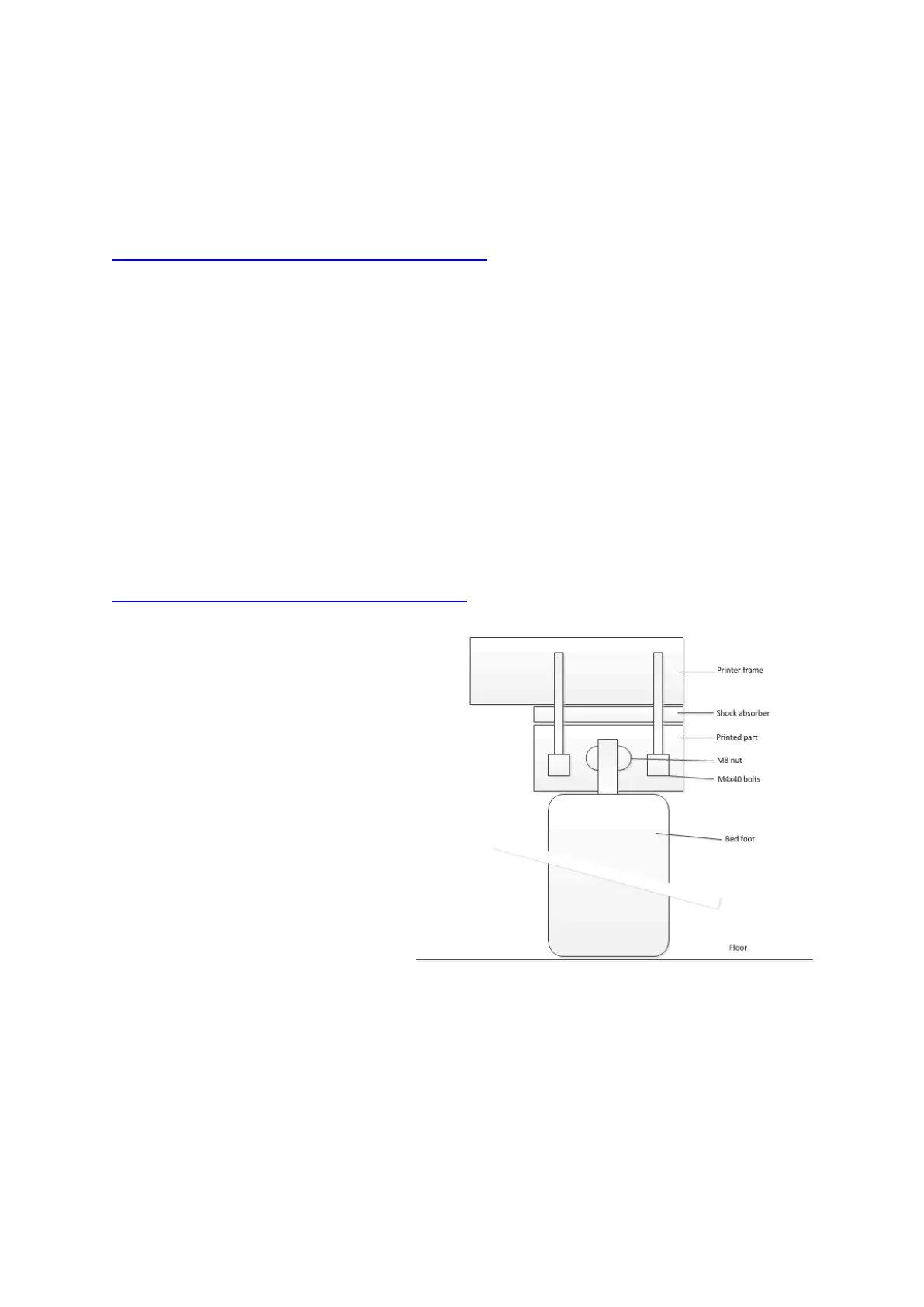

Optional – put your printer on feet

As you’ve witnessed already with the bed levelling exercise, access to parts under

the bed is not too easy. In addition, the printer is vibrating significantly, considering

the energy of the big bed with glass when reverting direction.

I saw several mods online for adding higher feet to the printer. I personally made an

upgrade here:

https://www.thingiverse.com/thing:3762782

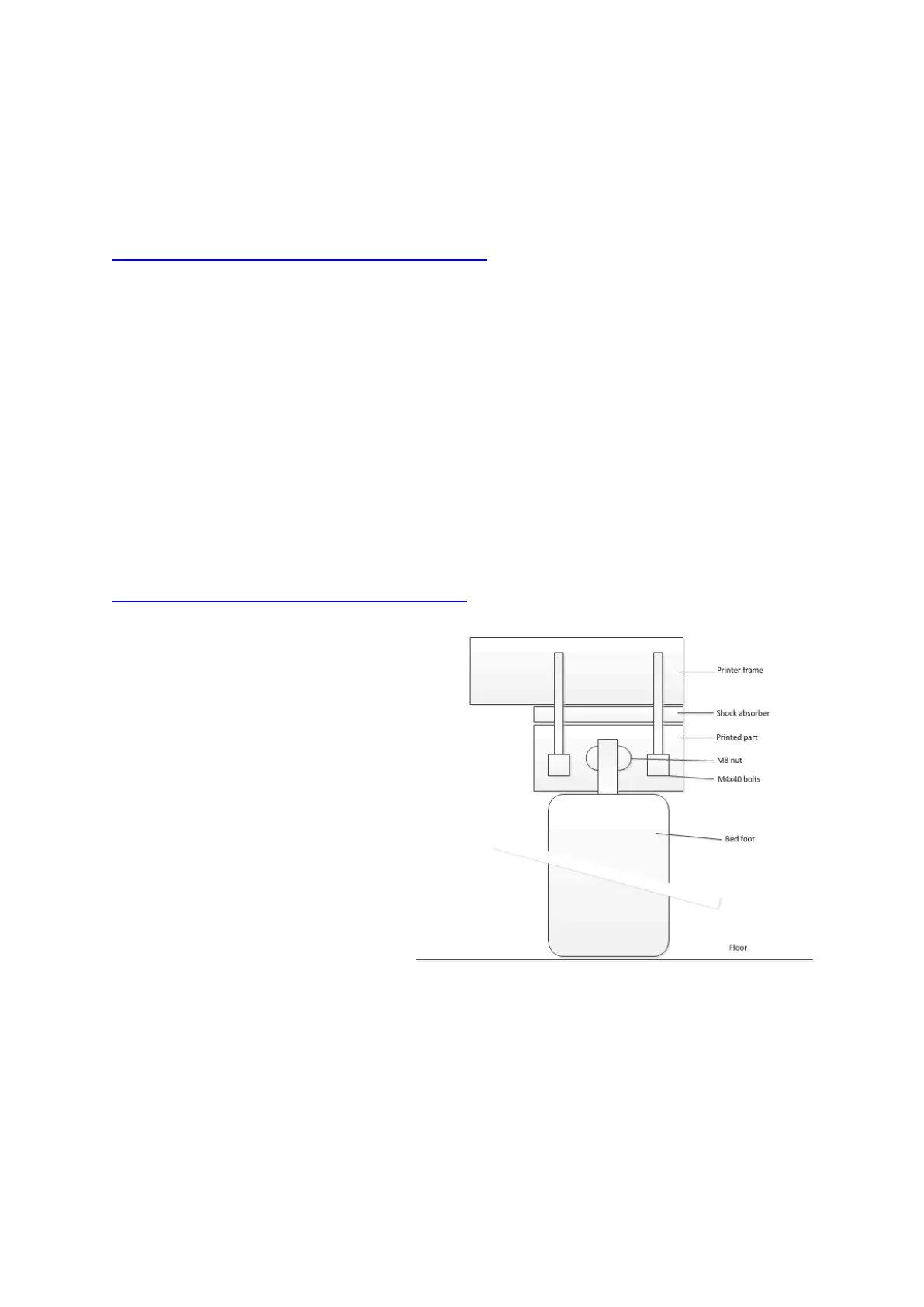

This raises the height of the

printer, composed of a top printed

block replacing the stock block, a

layer of shock absorbing material,

and a locking hole for an M8 nut

for adding any size of standard

bed feet with M8 rod.

Bed feet (in wood, metal, etc.) are

inexpensive, very sturdy, and

available in almost any height as

you need.

Additional benefit is that the space

below the printer can be used to

create (well accessible) cable

paths as well as to store spare parts. Around 20cm high bed feet will allow storage

box about the size of shoe boxes. The higher, the more vibrations, so find a balance.

IMPORTANT RECOMMENDATION: with or without extended feet, I recommend

that you take the time to level your printer frame when you put it in location.

Especially in the case where you add bed feet and place the printer on the ground, it

is important that you add spacers under the feet so that the frame is well level in both

X and Y directions. This will greatly diminish bed warping, friction on the cart wheels,

etc. However, this will not replace a good bed levelling assistance later on.

Loading...

Loading...