142

8

Disassembling Procedure

Work Procedure Point

WARNING

Before disassembling work, be sure

to turn OFF all power supplies.

Procedure for Removing Oil

Pump

*1

*1

After the oil pump (M1P) is

replaced, the cumulative oil

pump (M1P) running time

must be reset.

Input “0012” into the

parameter n035, and reset

the cumulative pump running

time.

(refer to page 67)

*2

Removing grommet

Grommet is used to maintain

dust preventive performance

in the switch box.

扌

If any lead wire is taken out

from the grommet hole, be

sure to replace the grommet.

1

Remove the switch box cover, top

panel, back panel, left side panel,

and right side panel in accordance

with “Procedure for Removing

Outside Panel Block (P.133)”.

1

Remove the control panel mounting

plate in accordance with “Procedure

for Removing Switch Box (P.136)”

.

1

Place a receptacle to receive oil

under the evaporator.

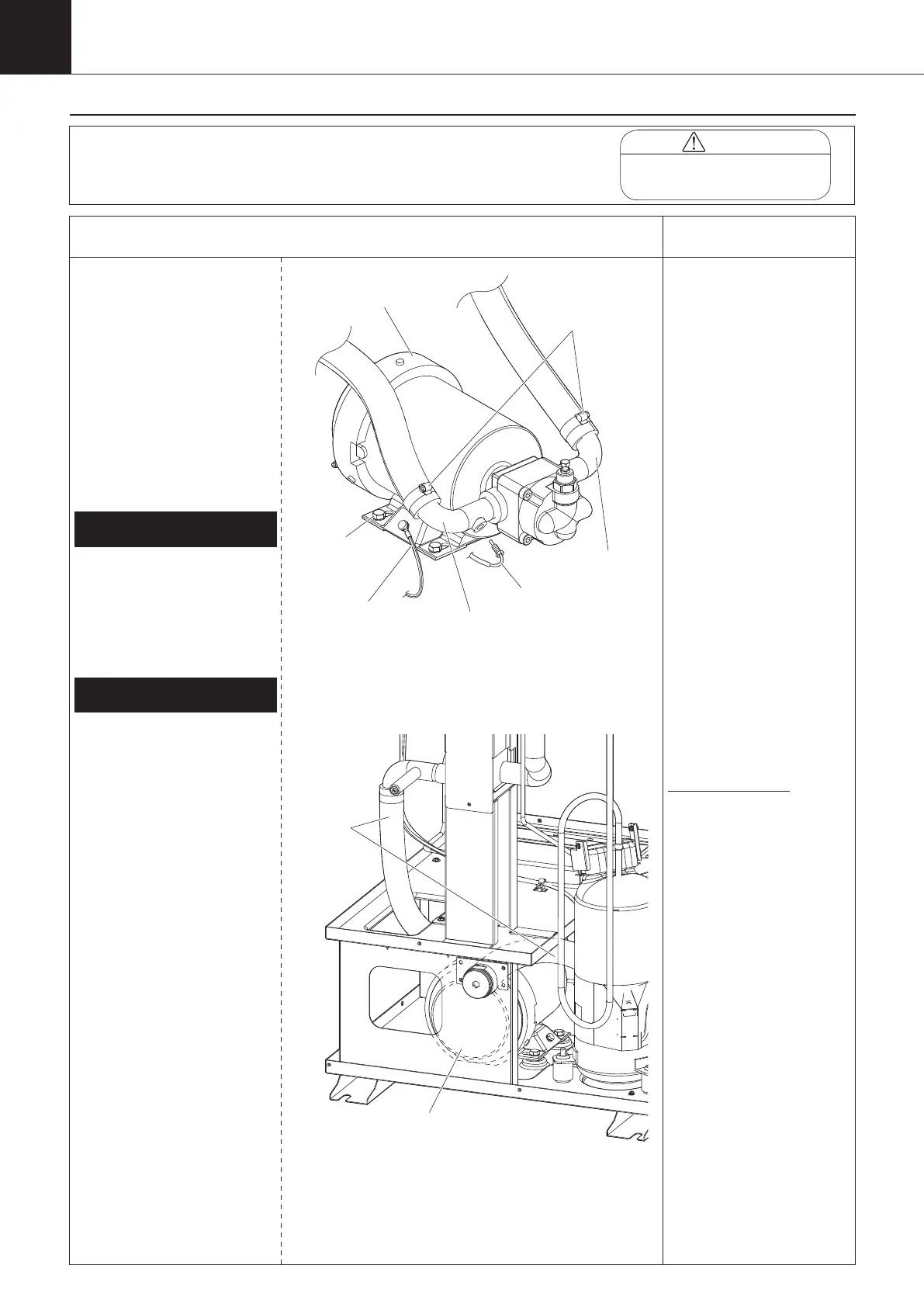

① Loosen two hose bands

(oil outlet/inlet pipe), and

discharge oil.

② Remove the inlet oil

thermistor (Th-4).

1.

Discharging oil

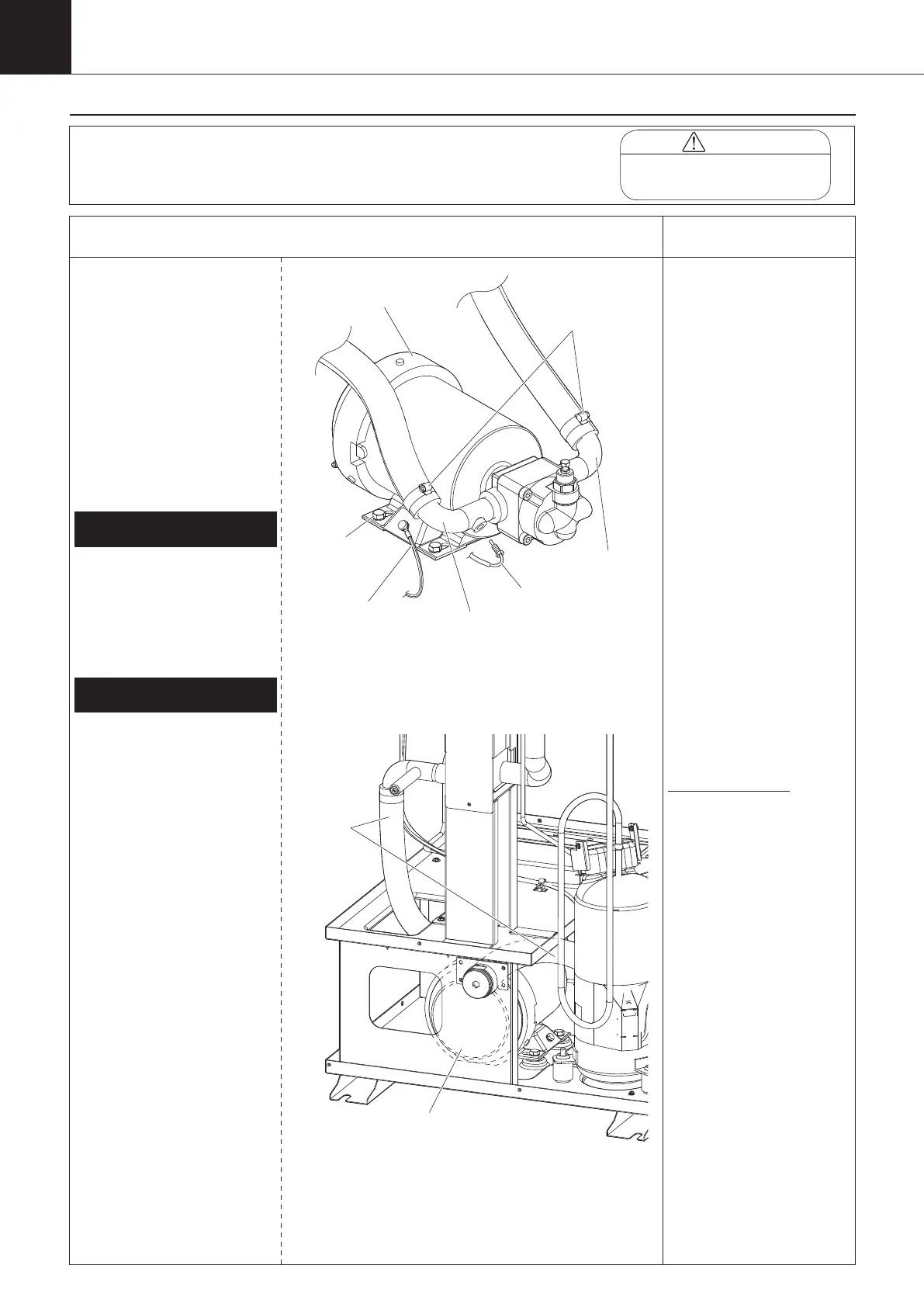

① Disconnect the earth

ground wire.

② Disconnect the oil pump

lead wire connected to

the secondary side of the

overcurrent relay in the

switch box and pull it out

from the grommet (*2) of

the switch box. Remove

the band banding the oil

pump lead wires in the oil

cooling unit.

③ Unscrew the four fixing

screws from the pump.

④ Remove the two front

hose bands that are

connected to the oil pump

(M1P).

⑤ Pull the rubber hose and

remove the oil pump

(M1P).

2.

Removing oil pump (M1P)

Hose band

(two places)

Oil outlet pipe

Earth ground wire

(M1P)

Oil inlet pipe

Inlet oil thermistor

(Th-4)

Oil pump

(M1P)

00_PB00540A_M10.indb 142 2023/08/09 12:59:23

Loading...

Loading...