1111

Stop ValVe operatIon method

The gure below shows the name of each part required in

handling the stop valve. At the time of shipment, the stop

valve is closed.

CAUTION

•Be Sure to open the Stop ValVe.

•Inadequate torque may cauSe leakage of refrIgerant.

Opening Procedure

1. Remove the valve lid and use a hexagonal wrench to

turn valve counterclockwise.

2. Turn valve until shaft stops.

3. Then turn valve until designated torque as shown in

below table is achieved (3.5 - 5.0 ton only due to back

sealing type valve).

4. Put valve lid on valve.

Closing Procedure

1. Remove the valve lid and use a hexagonal wrench to

turn valve clockwise.

2. Turn valve until shaft stops.

3. Then turn valve until designated torque as shown in

below table is achieved.

4. Put valve lid on valve.

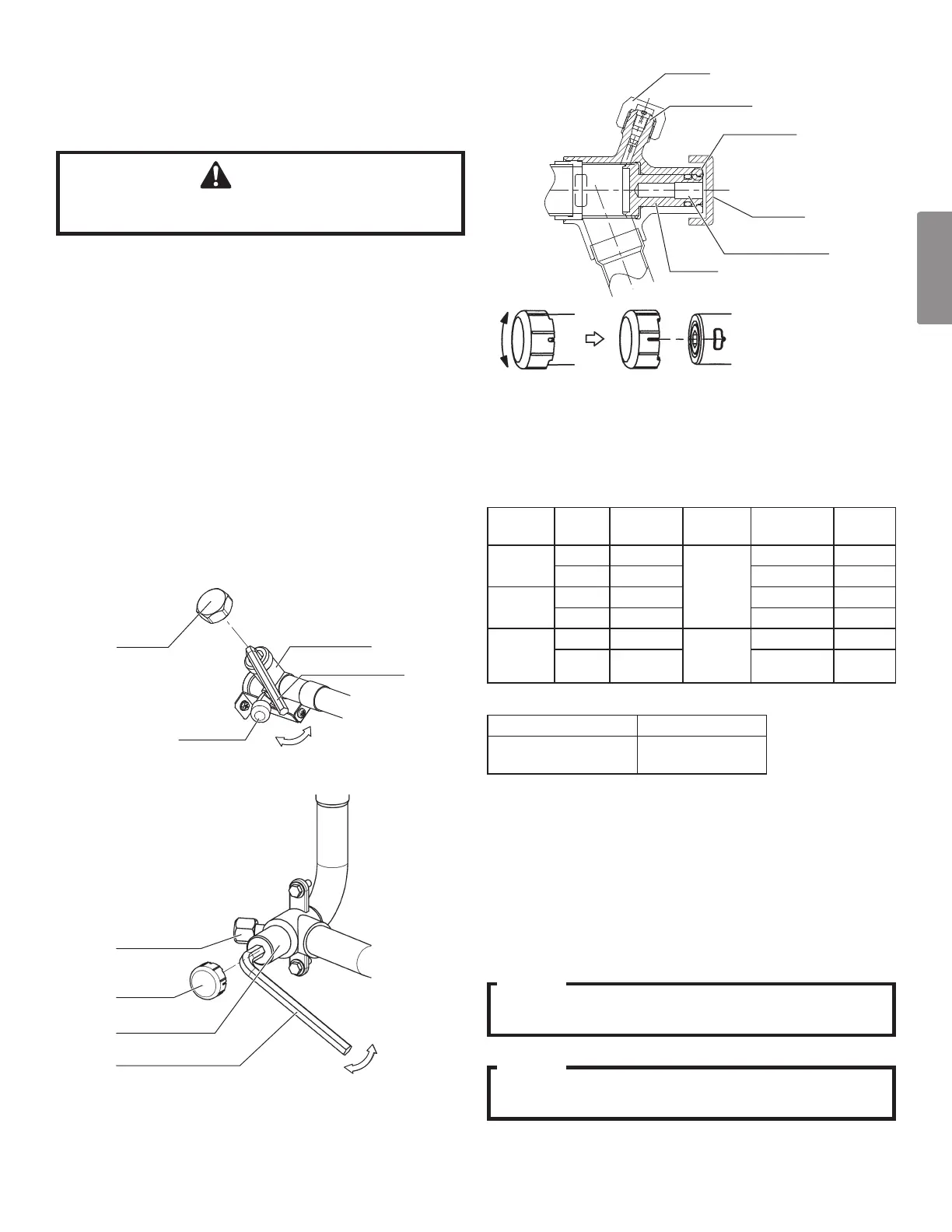

<1.5 - 3.0 ton>

Service port

Hexagonal wrench

Close

*Rotate lightly until

it stops, then tighten

1/4 - 1/2 rotation.

Open

Valve lid

Gas stop valve

<3.5 - 5.0 ton>

Valve lid

Service port

Stop valve

Hexagonal wrench

Close

Open

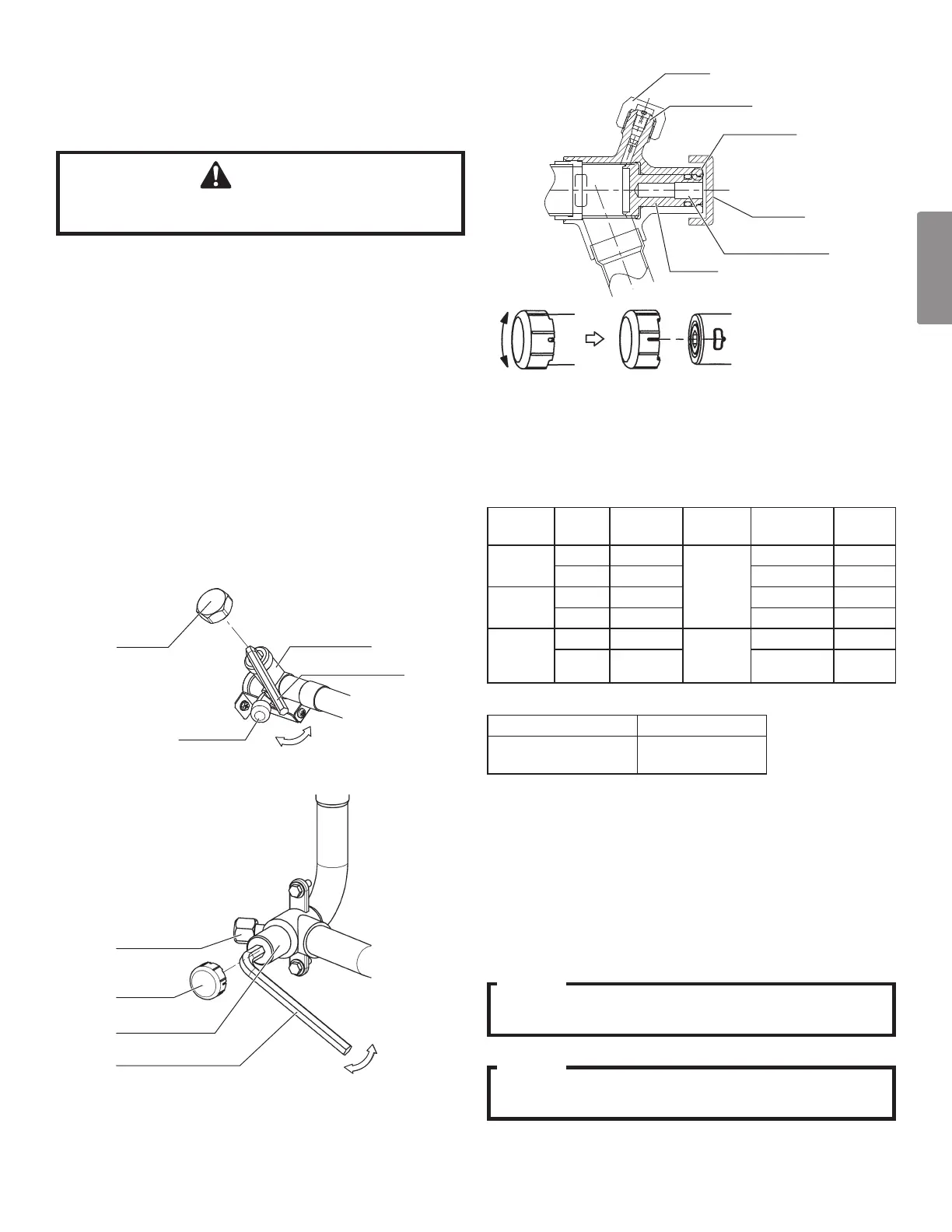

Service port

Cap

Valve lid

Hole for

hexagonal wrench

Shaft

Back sealing

* The illustration shows

the removal procedure.

Perform the actions in

the reverse order to

reattach.

Rotate the

valve lid 90°

to the right or

to the left.

Align the recess of the

valve lid and the T-joint

on the valve body, then

remove the lid.

*To be sealed,

follow step 3 of

Opening Procedure.

* The illustrations above refer to 3.5 - 5.0 ton only.

Stop Valve

Tonnage Piping

Stop valve

size

Type

Tightening

torque

Wrench

size

1.5 - 2.0

ton

Liquid 3/8”

Front

sealing

type

6 - 8 N·m 3/16”

Gas 3/4” 19 - 21 N·m 5/16”

2.5 - 3.0

ton

Liquid 3/8” 6 - 8 N·m 3/16”

Gas 7/8” 19 - 21 N·m 5/16”

3.5 - 5.0

ton

Liquid 3/8” Front and

back seal-

ing type

5 - 7 N·m 4 mm

Gas 7/8” 19 - 21 N·m 8 mm

Service Port

Tighten Torque

Service Port

(3.5 - 5.0 ton only)

10.7 – 14.7 N·m

SyStem Start-up procedure

GENERAL NOTES:

Adequate refrigerant charge for the matching indoor unit

and line set is supplied with the heat pump. If liquid line set

exceeds factory charge length, refrigerant should be added

based on liquid line. Refer pages 16-18 for calculation

of refrigerant charge based on line set length.

VIolatIon of epa regulatIonS may reSult In fIneS or other

penaltIeS.

NOTICE

all unItS Should haVe a hIgh Voltage power Supply connected

2 hourS prIor to Startup.

NOTICE

Loading...

Loading...