1818

Step 2. connect heat pump to SyStem

CAUTION

open the lIquId ValVe fIrSt!

If the SuctIon SerVIce ValVe IS opened fIrSt, oIl from the com-

preSSor may Be drawn Into the Indoor unIt, reStrIctIng refrIger-

ant flow and affectIng operatIon of the SyStem.

CAUTION

poSSIBle refrIgerant leak!

to aVoId a poSSIBle refrIgerant leak, open the SerVIce ValVeS

untIl the top of the Stem IS 1/8” from the retaIner.

CAUTION

enSure ValVeS are open and addItIonal charge IS added per

chart Before applyIng power.

Charge additional refrigerant calculated by STEP formula &

table from liquid service valve. (NOT from suction side.)

When opening service valves, open each valve only until the

top of the stem is 1/8” from the valve. To avoid loss of refriger-

ant, DO NOT apply pressure to the retainer. When opening

valves without a retainer, remove service valve cap and insert

a hex wrench into the valve stem and back out the stem by

turning the hex wrench counterclockwise.

After the refrigerant charge has bled into the system, open

the liquid service valve. The service valve cap is the second-

ary seal for the valves and must be properly tightened to

prevent leaks. Make sure cap is clean and apply refrigerant

oil to threads and sealing surface on inside of cap. Tighten

cap nger-tight and then tighten additional 1/6 of a turn to

properly seat the sealing surfaces.

Break vacuum by fully opening liquid and suction base valve.

NOTE: 1.5 - 3.0 ton have front seating valves. 3.5 - 5.0 ton

have front / back seating valve. Refer detail function on page

11. It is not necessary to force the stem tightly against the

rolled lip.

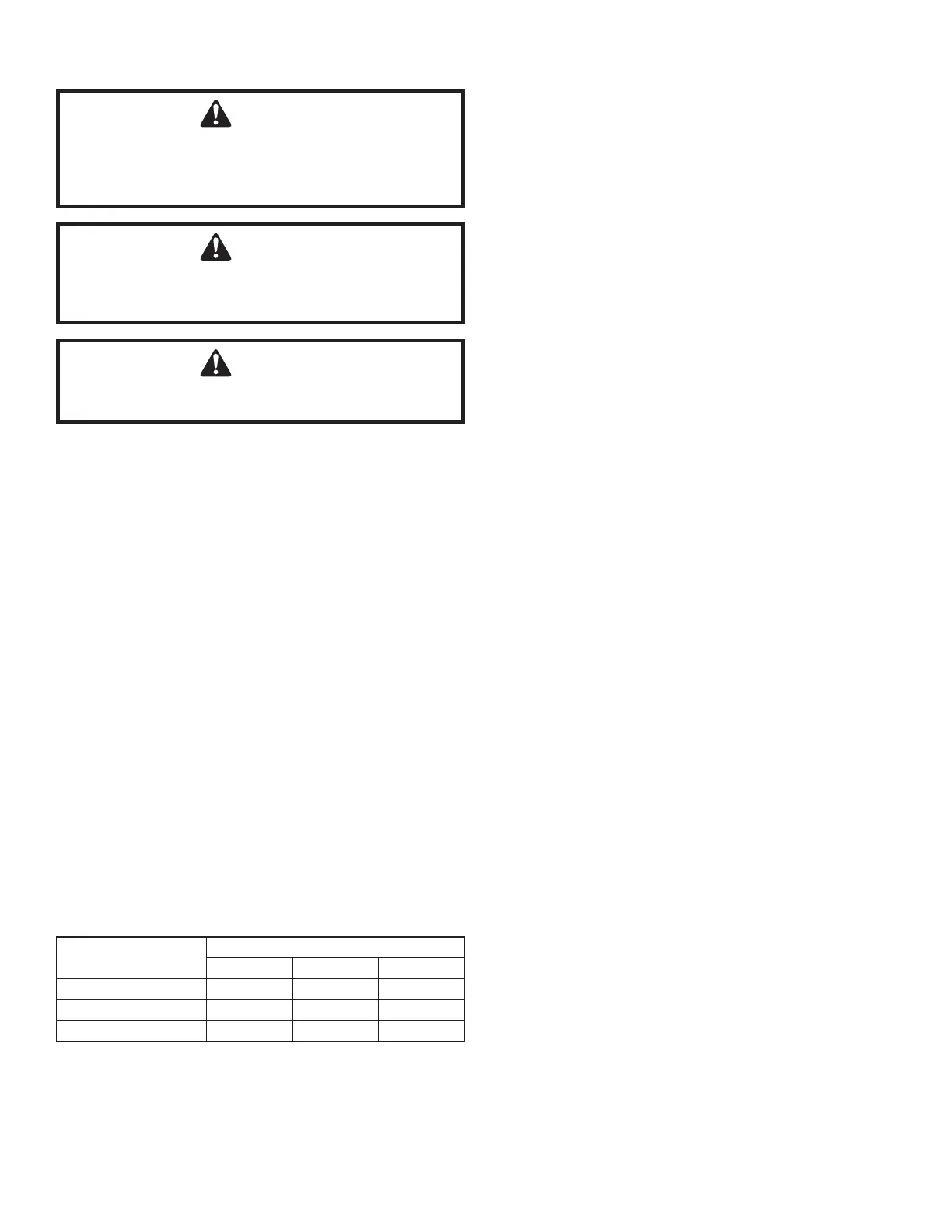

equIValent length calculatIon

NOTE: The following table lists the equivalent length gained

from adding bends to the suction line. Properly size the suc-

tion line to minimize capacity loss.

Type of Elbow Fitting

Inside Diameter

3/4 7/8 1 1/8

90° short radius 1.7 2 2.3

90° long radius 1.5 1.7 1.6

45° radius 0.7 0.8 1

unit: inch

Step 3. SyStem Start-up teSt

For a detailed procedure, please visit the Daikin One+ website

at https://www.daikinone.com

addItIonal charge adjuStIng procedure

Step 4. adjuSt refrIgerant leVel

Using service equipment, add or recover refrigerant according

to the refrigerant calculation. Allow system to stabilize for 20

minutes after adjusting charge level.

Step 5. meaSure SuBcoolIng to VerIfy

proper charge

If want to adjust charging by checking “Subcooling”, please

follow below.

NOTE: Charging equipment must use dedicated PVE oil

gauges and hoses.

1. Purge gauge lines.

2. Connect service gauge manifold to liquid base valve

service ports.

3. Convert the liquid pressure to temperature using a

temperature/pressure chart.

4. Temporarily install a thermometer on the liquid line at

the liquid line service valve.

Ensure the thermometer makes adequate contact and

is insulated for best possible readings.

5. Subtract the liquid line temperature from the converted

liquid pressure to determine subcooling.

6. Before starting the subcooling adjustment, make sure

the outdoor ambient temperature is in a below range

and the unit is operating at 100% capacity.

If the unit is operating at 100% capacity which is ready

for charge by subcooling, seven segments will light up

as “cha”.

But, if the unit is not operating at 100% capacity which

is not ready for charging, seven segments will ush

as “cha”.

7. If the system subcooling is not within the range

as shown in the following table, adjust subcooling

according to the following procedure.

a. If subcooling is low, add charge to adjust the

subcooling as specied in the following table.

b. If subcooling is high, remove charge to lower the

subcooling to below charging table value.

Loading...

Loading...