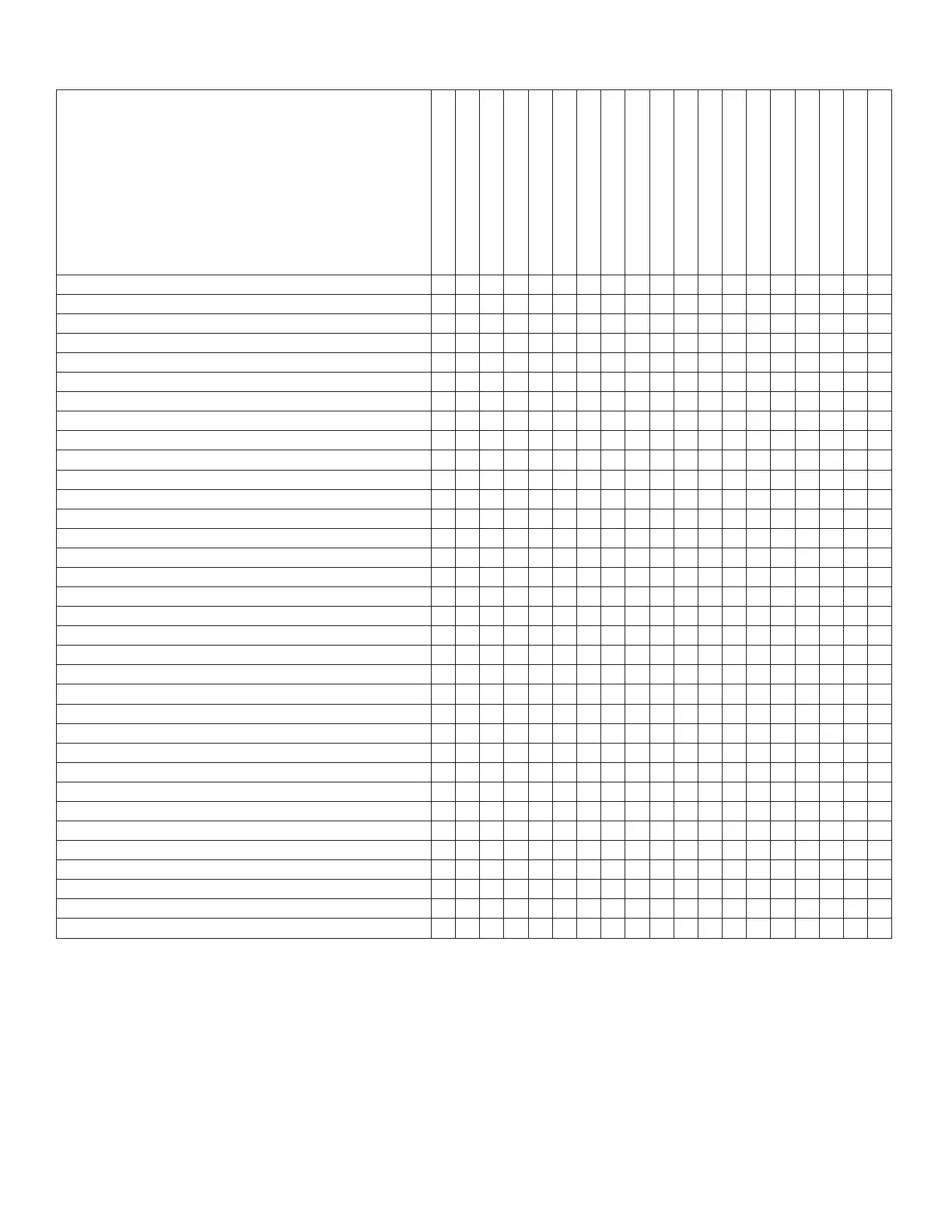

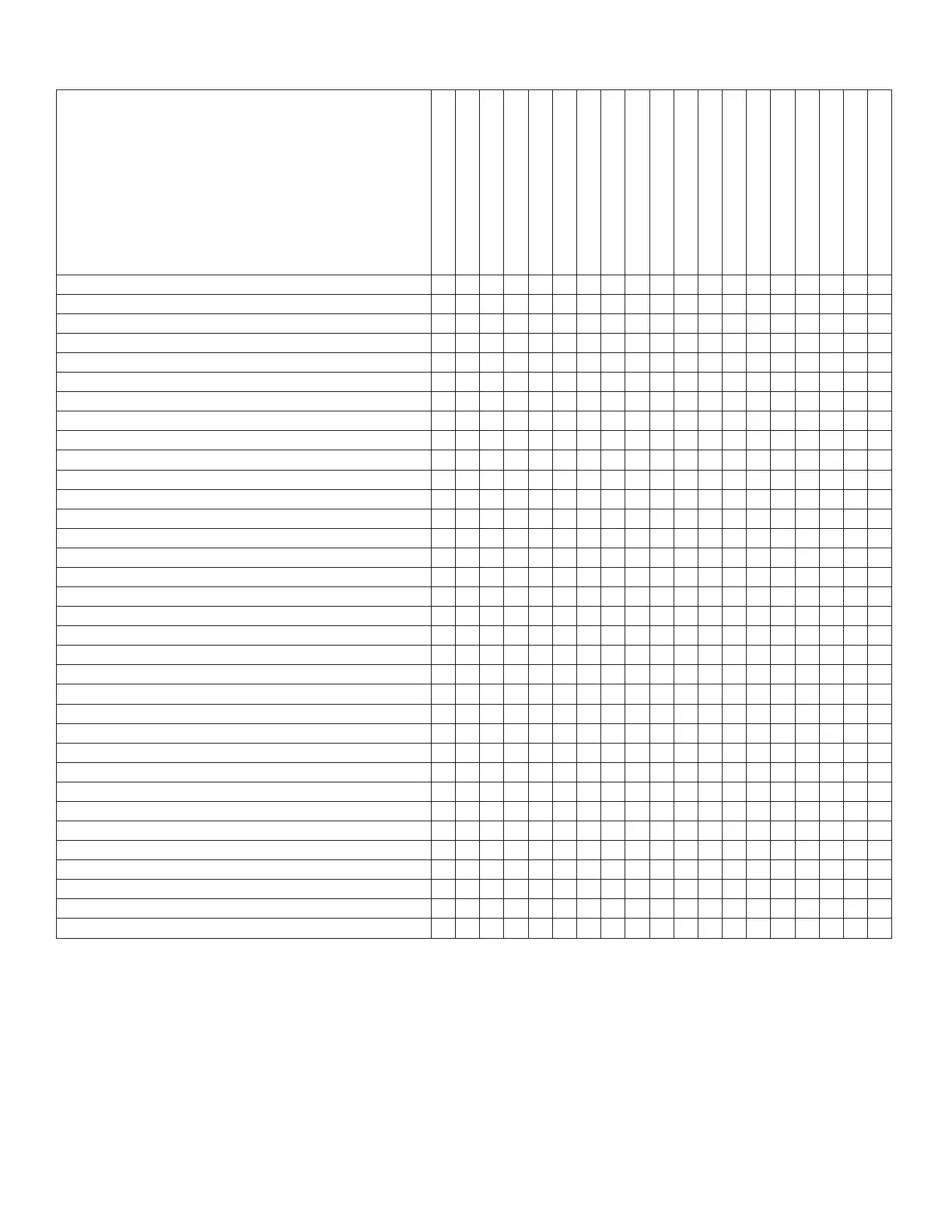

2424

coolIng analySIS chart

POSSIBLE CAUSE

X IN ANALYSIS GUIDE INDICATE

“POSSIBLE CAUSE”

Comp discharge temp > 200F

Comp discharge temp < 105F

Comp discharge SH > 72F

Comp discharge SH < 20F

High pressure > 500psi

High pressure < 255psi

LSV SC > 15F

LSV SC < 4F

OD SSV SH > 20F

OD SSV SH < 4F

Low pressure > 185psi

Low pressure < 100psi

Requested % demand < Actual

Requested % demand > Actual

Repeated stop/start

Weak cooling

No switch cooling

Noise

Stop operation

Liquid stop valve does not fully open

X X X X X X X X X X

Suction stop valve does not fully open

X X X X X X

Line set restriction

X X X X X X X X X X

Line set length is too long

X X X X X

Blocked lter-dryer

X X X X X X X X X X

ID EEV coil failure

X X X X X X X X X X X X X X X X X

ID EEV failure

X X X X X X X X X X X X X X X X

High Pressure switch failure

X

Pressure sensor failure

X X X X X X X

Suction temp sensor failure

X X X

Discharge temp sensor failure

X X X X X X X X X

Coil temp sensor failure

X X X X X X X X

Liquid temp sensor failure

Ambient temp sensor failure

X X X X X X X

OD recirculation

X X X X X X X

ID recirculation

X X X X X X X X

Dirty OD Heat-exchanger

X X X X X X X

Dirty ID Heat-exchanger

X X X X X X X X X

Outdoor Ambient temp is too high

X X X X X X X X

Outdoor Ambient temp is too low

X X X X X X X X X

ID suction temp is too high

X X

ID suction temp is too low

X X X X X X X X X

Mixture of non-condensible gas

X X X X X X X X X X

OD fan motor failure

X X X X X X X X X

Over charge

X X X X X X X X X X

Under charge

X X X X X X X X X

Leak

X X X X X X X X X X X

OD Control Board Failure

X

ID Failure

X X X X X X X X X X X X X X X X X X

Compressor failure

X X X X X X X X X X

Compressor and Gas furnace are operating at the same time

X

Cooling loop is not attached

X X X

Cooling loop grease is not enough

X X X

Low ID CFM

X X X X X X X X X

Outdoor Normal Temperature Operating Range for Cooling Analysis: 67-115°F / Indoor Normal Temperature Operating Range: 65 - 85°F

Loading...

Loading...