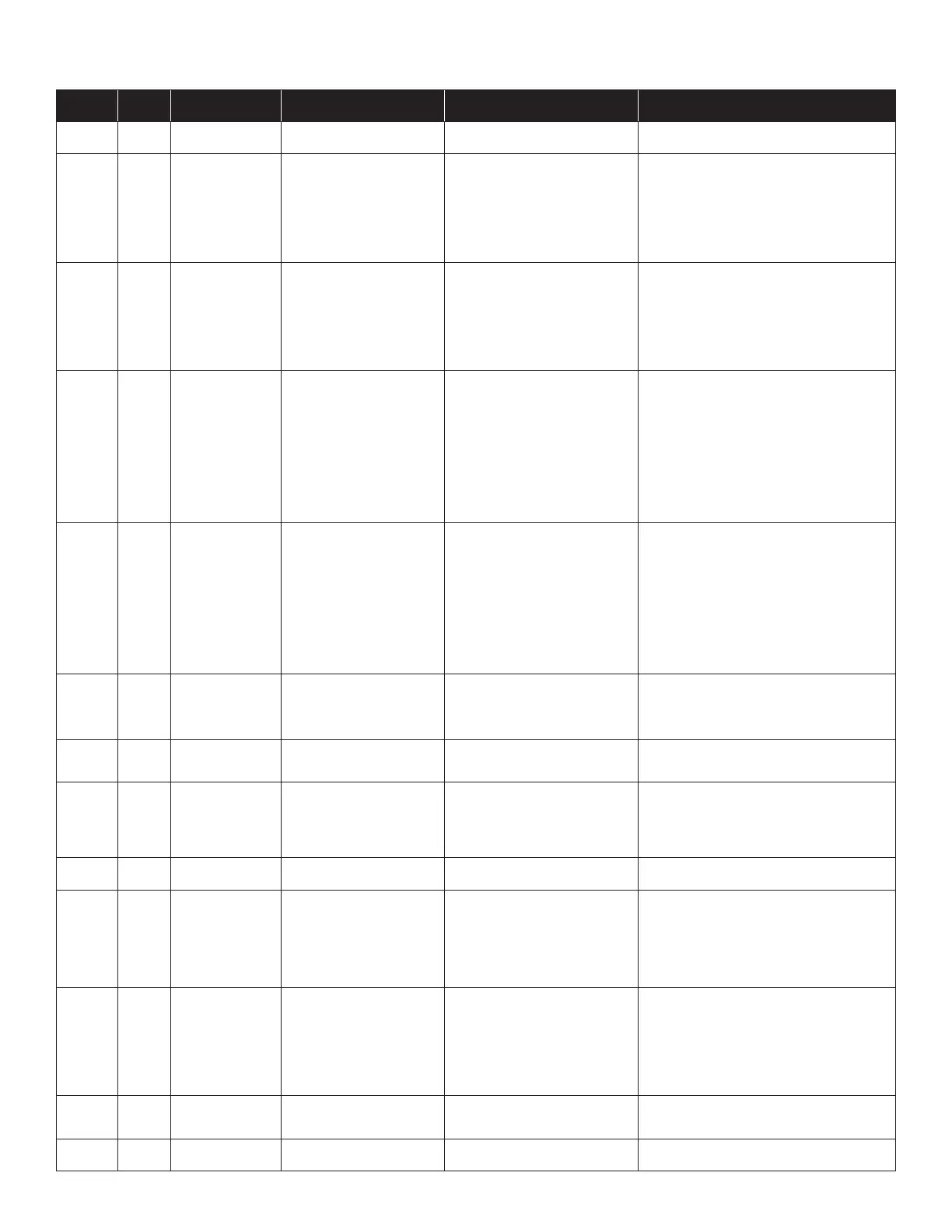

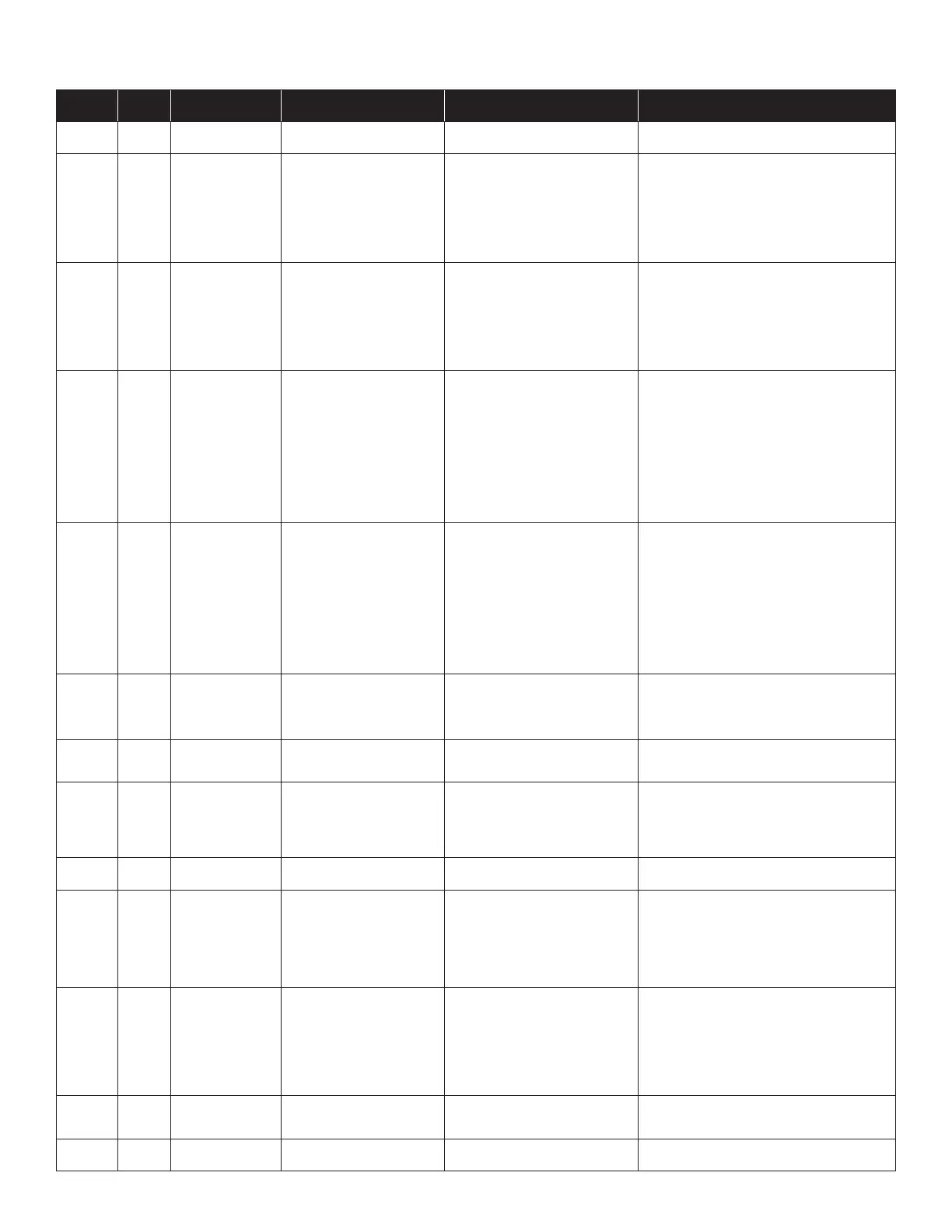

2626

trouBleShootIng

ClimateTalk

Fault Code

PCB LED

Display

Transmitted ClimateTalk

Message

Thermostat Fault Probable Causes Corrective Actions

12 E12 OD CTRL FAIL1 Indicates a general memory error.

• High electrical noise

• Faulty control board

• Replace control board if necessary

13 E13

HI PRESSURE C

(C = CRITICAL)

This error indicates the equipment

is experiencing frequent high pres-

sure faults.

• Blocked/restricted heat pump coil and/

or lines

• Stop valve not completely open

• Overcharge

• Outdoor fan not running

• High pressure switch (HPS) inoperable

• Faulty indoor and outdoor EEV coil

• Faulty indoor and outdoor EEV

• Faulty control board

• Check and clean heat pump coil and/or lines

• Check the opening of stop valve, should be full open;

Repair/replace if needed

• Check refrigerant charge level; Adjust if needed

• Check outdoor fan motor & wiring; Repair/replace if

needed

• Check indoor and outdoor EEV; Replace if needed

• Check indoor and outdoor EEV coil; Replace if needed

• Replace control board if necessary

14 -

HI PRESSURE M

(M = MINOR)

This error indicates the equipment

is experiencing frequent high pres-

sure faults. Control has determined

continued operation is acceptable.

This indicates they may be a prob-

lem with the equipment.

• Blocked/restricted heat pump coil and/

or lines

• Stop valve not completely open

• Overcharge

• Outdoor fan not running

• High pressure switch (HPS) inoperable

• Faulty indoor and outdoor EEV coil

• Faulty indoor and outdoor EEV

• Faulty control board

• Check and clean heat pump coil and/or lines

• Check the opening of stop valve, should be full open;

Repair/replace if needed

• Check refrigerant charge level; Adjust if needed

• Check outdoor fan motor & wiring; Repair/replace if

needed

• Check indoor and outdoor EEV; Replace if needed

• Check indoor and outdoor EEV coil; Replace if needed

• Replace control board if necessary

15 E15 LOW PRESSURE C

This error indicates the equipment

is experiencing frequent low pres-

sure faults.

• Stop valve not completely open

• Restriction in refrigerant lines

• Low refrigerant charge

• Refrigerant leak

• Low pressure sensor inoperable or not

properly connected

• Indoor fan motor not functioning correctly

• Faulty indoor and outdoor EEV coil

• Faulty indoor and outdoor EEV

• Faulty control board

• Check the opening of stop valve, should be full open;

Repair/replace if needed

• Check for restrictions in refrigerant line; Repair/replace

if needed

• Check refrigerant charge level; Adjust if needed

• Test for system leaks using leak test procedure

• Check the connection to low pressure sensor; Repair/

replace if needed

• Check indoor and outdoor EEV; Replace if needed

• Check indoor and outdoor EEV coil; Replace if needed

• Check indoor blower motor & wiring; Repair/replace if

needed

• Replace control board if necessary

16 - LOW PRESSURE M

This error indicates the equipment

is experiencing frequent low pres-

sure faults. Control has determined

continued operation is acceptable.

This indicates they may be a prob-

lem with the equipment.

• Stop valve not completely open

• Restriction in refrigerant lines

• Low refrigerant charge

• Refrigerant leak

• Low pressure sensor inoperable or not

properly connected

• Indoor fan motor not functioning correctly

• Faulty indoor and outdoor EEV coil

• Faulty indoor and outdoor EEV

• Faulty control board

• Check the opening of stop valve, should be full open;

Repair/replace if needed

• Check for restrictions in refrigerant line; Repair/replace

if needed

• Check refrigerant charge level; Adjust if needed

• Test for system leaks using leak test procedure

• Check the connection to low pressure sensor; Repair/

replace if needed

• Check indoor and outdoor EEV; Replace if needed

• Check indoor and outdoor EEV coil; Replace if needed

• Check indoor blower motor & wiring; Repair/replace if

needed

• Replace control board if necessary

17 E17 COMPRESSOR FAIL

This error indicates the equipment

is experiencing frequent compres-

sor faults.

• Stop valve not completely open

• The compressor wire is lost phase

• Compressor motor failure

• Check the opening of stop valve, should be full open;

Repair/replace if needed

• Check the wire between control board and compressor

• Inspect compressor motor for proper function; Replace

if necessary

18 E18 OD CTRL FAIL2

Indicates the control board may

need to be replaced.

• Outdoor fan motor not connected properly

• Faulty control board

• Electrical Noise

• Check wiring from Outdoor fan motor to control board;

Repair if needed

• Replace control board if necessary

19 E19 PCB OR FAN FAIL

This error indicates the equipment

is experiencing frequent outdoor

control board and/or motor faults.

• Obstruction in fan rotation

• Outdoor fan motor not connected properly

• Outdoor fan not running

• Faulty control board

• Electrical Noise

• Check and clean grille of any debris

• Check wiring from Outdoor fan motor to control board;

Repair if needed

• Check outdoor fan motor & wiring; Repair/replace if

needed

• Replace control board if necessary

20 E20 EEV OPEN CKT EEV coil is not connected.

• Outdoor EEV coil is not connected

• Faulty outdoor EEV coil

• Check outdoor EEV coil connection

Repair/replace as needed

21 E21 EEV CTRL FAIL

This error indicates the equipment

is experiencing frequent low dis-

charge superheat faults.

• Thermistors inoperable or improperly

connected

• Faulty indoor and outdoor EEV coil

• Faulty indoor and outdoor EEV

• Over charge

• Faulty pressure sensor

• Faulty control board

• Check the connection to thermistors; Repair/replace if

needed

• Check indoor and outdoor EEV coil; Repair/replace if

needed

• Check indoor and outdoor EEV; Replace/repair if needed

• Check refrigerant charge level; Adjust if needed

• Check pressure sensor; Repair/replace if needed

• Replace control board if necessary

22 E22 HI DISCH TEMP

This error indicates the equipment

is experiencing frequent high

discharge temperature faults.

Discharge thermistor is not put in

correct position.

• Discharge thermistor inoperable or

improperly connected

• Discharge thermistor is put in incorrect

position or off

• The compressor enclosure temperature

is too high

• Low refrigerant charge

• Overcharge

• Faulty compressor

• Check discharge thermistor resistance and connections;

Repair/replace as needed

• Check discharge thermistor position

• Check refrigerant charge level; Adjust if needed

• Check the compressor; Repair/replace if needed

23 E23 DISCH TEMP FAIL

The control has detected that the

Discharge Temperature Sensor is

out of range.

• Discharge thermistor inoperable or

improperly connected

• Check discharge thermistor resistance and connections;

Repair/replace as needed

24 E24 HPS OPEN The high pressure switch is open. • High pressure switch (HPS) inoperable

• Check resistance on HPS to verify operation; Replace

if needed

Loading...

Loading...