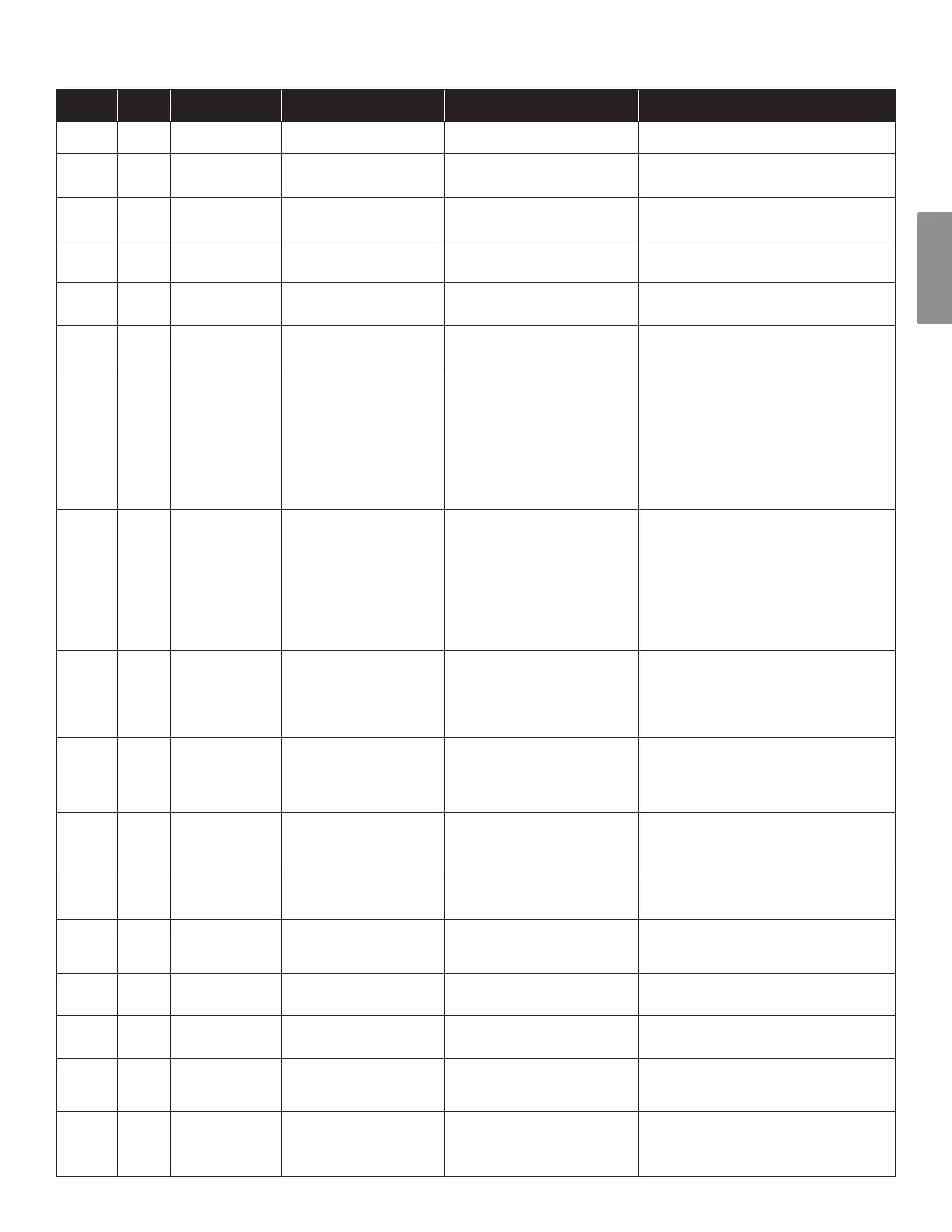

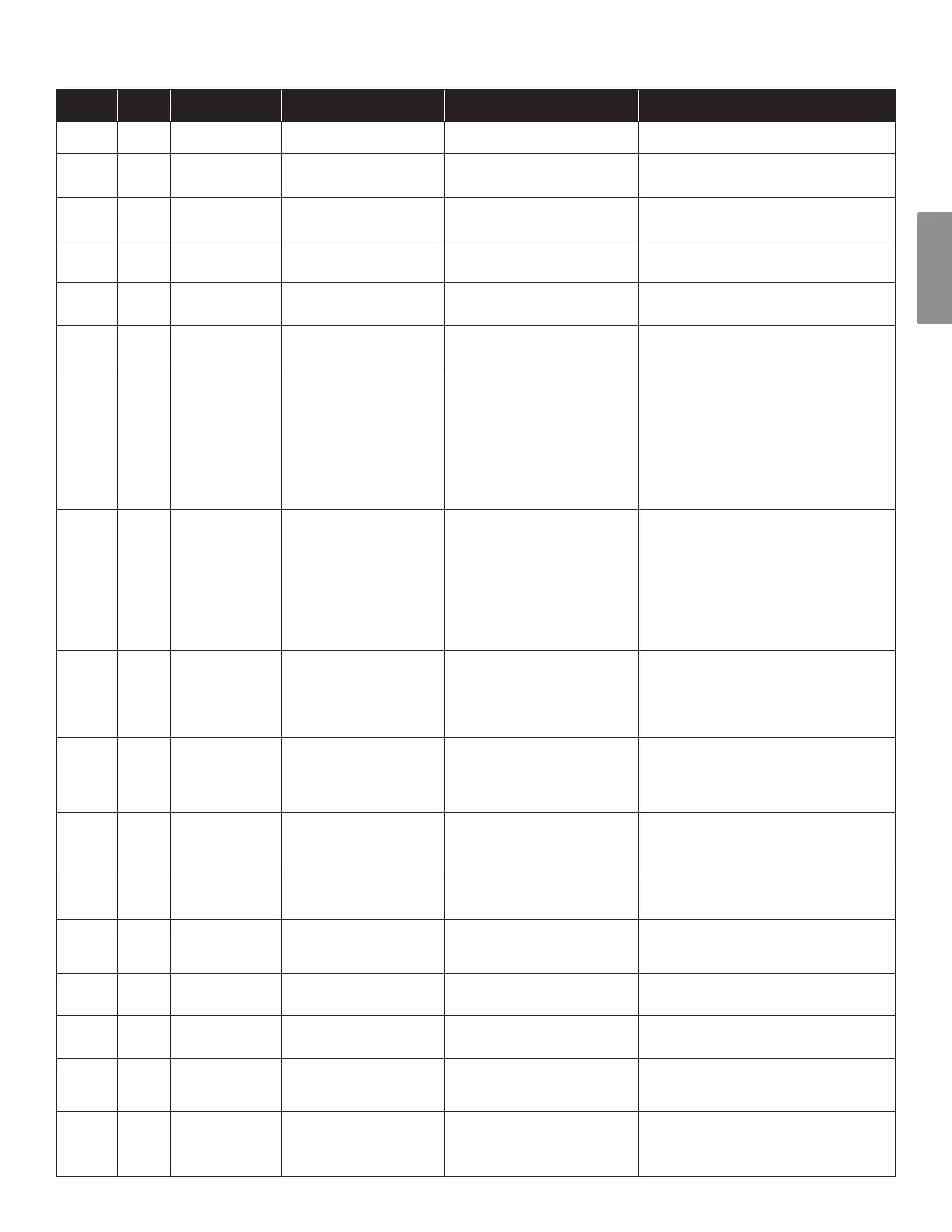

2727

trouBleShootIng

ClimateTalk

Fault Code

PCB LED

Display

Transmitted ClimateTalk

Message

Thermostat Fault Probable Causes Corrective Actions

25 E25 AIR SENSOR FLT

The outdoor air temperature sensor

is open or shorted.

• Faulty outdoor thermistor sensor or

disconnect

• Inspect and test sensor; Replace sensor if needed

26 E26 PRESSURE SENSOR

The control determines that the

pressure sensor is not reacting

properly.

• Pressure sensor inoperable or not prop-

erly connected

• Check the connection to pressure sensor; Repair/replace

if needed

27 E27 COIL TEMP FAIL1

The control has detected that the

Outdoor Coil Defrost Temperature

Sensor is out of range.

• Outdoor defrost thermistor inoperable or

not properly connected

• Check the connection to OD defrost thermistor; Repair/

replace if needed

28 E28 COIL TEMP FAIL2

The control has detected that the

Outdoor Coil Temperature Sensor is

out of range.

• Outdoor coil thermistor inoperable or not

properly connected

• Check the connection to OD coil thermistor; Repair/

replace if needed

29 E29 LIQ TEMP FAIL

The control has detected that the

Liquid Temperature Sensor is out

of range.

• Liquid thermistor inoperable or not prop-

erly connected

• Check the connection to liquid thermistor; Repair/replace

if needed

30 E30 OD CTRL FAIL3

Indicates the control board may

need to be replaced.

• Wiring to control board disconnected

• Faulty control board

• Electrical Noise

• Check wiring to control board; Repair as needed

• Replace control board if necessary

32 E32 HI TEMP CTRL1

This error indicates the equipment

is experiencing high temperature

faults on the outdoor control board.

• Ambient air conditions too high

• Stop valve not completely open

• Cooling bracket screw(s) missing or not

properly fastened <3.5 - 5.0 ton only>

• No or poor thermal grease coating

between cooling plumbing and cooling

bracket on control board <3.5 - 5.0 ton

only>

• No ow or limited ow through control

board cooling circuit (potential restriction

in line or low refrigerant) <3.5 - 5.0 ton

only>

• Cycle power; re-try during usable ambient temperature

range

• Check grease applying condition <3.5 - 5.0 ton only>

• Check screw tightening condition <3.5 - 5.0 ton only>

• Check for restriction in line

• Check refrigerant charge level; Adjust if needed

• Check the opening of stop valve, should be full open;

Repair/replace if needed

33 - HI TEMP CTRL2

This error indicates the equipment

is experiencing high temperature

faults on the outdoor control board.

Control has determined continued

operation is acceptable. This indi-

cates they may be a problem with

the equipment.

• Ambient air conditions too high

• Stop valve not completely open

• Cooling bracket screw(s) missing or not

properly fastened <3.5 - 5.0 ton only>

• No or poor thermal grease coating

between cooling plumbing and cooling

bracket on control board <3.5 - 5.0 ton

only>

• No ow or limited ow through control

board cooling circuit (potential restriction

in line or low refrigerant) <3.5 - 5.0 ton

only>

• Cycle power; re-try during usable ambient temperature

range

• Check grease applying condition <3.5 - 5.0 ton only>

• Check screw tightening condition <3.5 - 5.0 ton only>

• Check for restriction in line

• Check refrigerant charge level; Adjust if needed

• Check the opening of stop valve, should be full open;

Repair/replace if needed

34 E34 CURRENT SPIKE

Board detected a high current con-

dition. This indicates the potential

for a short circuit.

• Current spike in supply

• Stop valve not completely open

• The compressor wire is lost phase

• Faulty control board

• Faulty compressor

• Check power supply for in-rush current during start-up or

steady state operation

• Check the opening of stop valve, should be full open;

Repair/replace if needed

• Check the wire between control board and compressor

• Replace control board if necessary

• Check the compressor; Repair/replace if needed

35 E35 HIGH CURRENT

Board detected a high current

condition.

• Short circuit condition

• Stop valve not completely open

• Overcharge

• Faulty control board

• Faulty compressor

• Check installation clearances.

• Check the opening of stop valve, should be full open;

Repair/replace if needed

• Check refrigerant charge level; Adjust if needed

• Replace control board if necessary

• Check the compressor; Repair/replace if needed.

36 E36 STARTUP ERROR

The control encountered an abnor-

mal condition during the startup

procedure.

• Blocked/restricted heat pump coil and/

or lines

• The compressor wire is lost phase

• Inconsistent compressor load

• Faulty control board

• Check and clean heat pump coil and/or lines

• Check the wire between control board and compressor

• Replace control board if necessary

37 E37 OD CTRL FAIL4

Indicates the control board may need

to be replaced.

• Outdoor fan motor not connected properly

• Faulty control board

• Check wiring from Outdoor fan motor to control board;

Repair if needed

• Replace control board if necessary

38 E38 COMP VOLTAGE

The control has detected a voltage

related issue with the compressor.

• High or low voltage from supply

• The compressor wire is lost phase

• Faulty control board

• Correct low/high line voltage condition; Contact local utility

if needed

• Check the wire between control board and compressor

• Replace control board if necessary

39 E39 OD CTRL FAIL5

Indicates the control board may need

to be replaced.

• Thermistors inoperable or improperly

connected

• Faulty control board

• Check the connection to thermistors; Repair/replace if

needed

• Replace control board if necessary

40 E40 COMP MISMATCH

Control determines that its compres-

sor requirement is different than the

compressor capability.

• Memory card not correct

• Control board mismatch

• Check memory card data vs. heat pump model

• Verify control board size vs. heat pump model; Replace

control board if necessary

41 E41 LOW REFRIGERANT

The control has detected a low

refrigerant condition.

• Refrigerant leak

• Low refrigerant charge

• Thermistors inoperable or not properly

connected

• Test for system leaks using leak test procedure

• Check refrigerant charge level; Adjust if needed

• Check the connection to thermistor; Repair/replace if

needed

42 E42 LOW LINE VOLT

Control detects a low power supply

voltage condition.

• Low line voltage supply

• Check circuit breakers and fuses; Replace if needed

• Verify unit is connected to power supply as specied on

rating plate

• Correct low line voltage condition; Contact local utility if

needed

Loading...

Loading...