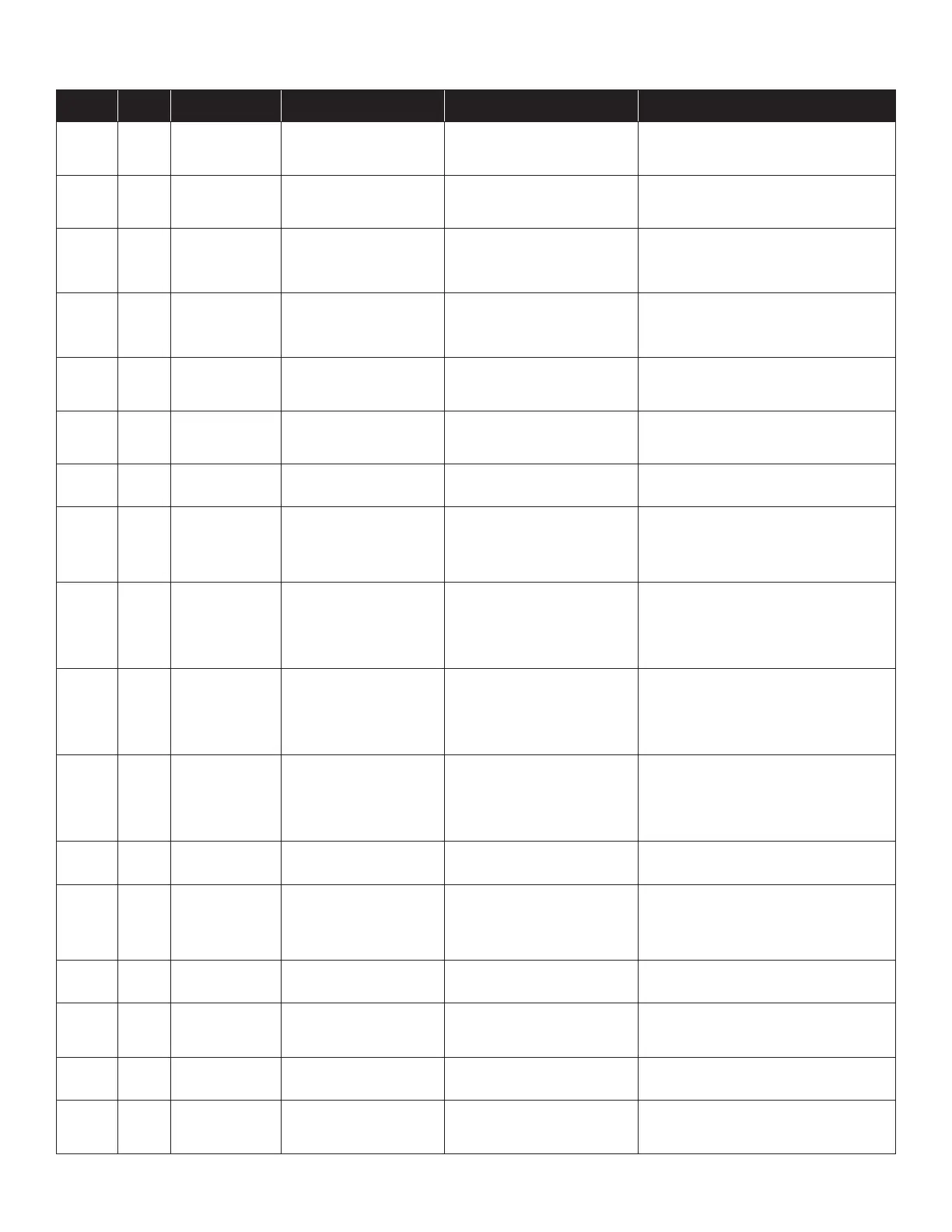

2828

trouBleShootIng

ClimateTalk

Fault Code

PCB LED

Display

Transmitted ClimateTalk

Message

Thermostat Fault Probable Causes Corrective Actions

43 E43 HIGH LINE VOLT

Control detects a high power supply

voltage condition.

• High line voltage supply

• Verify unit is connected to power supply as specied on

rating plate

• Correct high line voltage condition; Contact local utility if

needed

44 E44 OP TEMP RANGE

The control detects the outdoor

temperature outside recommended

operational range. Unit may continue

to operate normally.

• Ambient air conditions too high or low

• Cycle power; re-try during usable ambient temperature

range

45 E45 NO COOLING TEST

The control is unable to start the

Cooling mode test because indoor

heat has been turned on by ther-

mostat. Please set thermostat to off

position.

• Heat provided by secondary heating

source

• Turn off Furnace or heater using thermostat before

operation

47 E47 NO SYS VER TEST

The control is unable to start the

System Verication test because

indoor heat has been turned on by

thermostat. Please set thermostat to

off position.

• Heat provided by secondary heating

source

• Turn off Furnace or heater using thermostat before

operation

49 E49 NO CHARGE MODE

The control is unable to enter

Charging Mode because indoor heat

has been turned on by thermostat.

Please set thermostat to off position.

• Heat provided by secondary heating

source

• Turn off heater using thermostat before operation

50 E50 LINE VOLT CTRL

This indicates there is a voltage

issue on the control board. See

service manual for troubleshooting

information.

• High or low voltage from supply voltage or

frequency

• Faulty control board

• Noise

• Correct low/high line voltage condition; Contact local utility

if needed

• Replace control board if necessary

• Contact local utility if needed

51 E51 OD COMM ERROR

This indicates potential communica-

tion issues have been detected by

the outdoor control board.

• Communication wiring disconnected • Check communication wiring; Repair as needed

52 - COMP FAIL MINOR

This error indicates the equipment is

experiencing frequent compres-

sor faults. Control has determined

continued operation is acceptable.

This indicates they may be a problem

with the equipment.

• Stop valve not completely open

• The compressor wire is lost phase

• Compressor motor failure

• Check the opening of stop valve, should be full open;

Repair/replace if needed

• Check the wire between control board and compressor

• Inspect compressor motor for proper function; Replace if

necessary

53 - PCB OR FAN MIN

This error indicates the equipment is

experiencing frequent outdoor control

board and/or motor faults. Control

has determined continued operation

is acceptable. This indicates they

may be a problem with the equip-

ment.

• Obstruction in fan rotation

• Outdoor fan motor not connected properly

• Outdoor fan not running

• Faulty control board

• Noise

• Check and clean grille of any debris

• Check wiring from Outdoor fan motor to control board;

Repair if needed

• Check outdoor fan motor & wiring; Repair/replace if

needed

• Replace control board if necessary

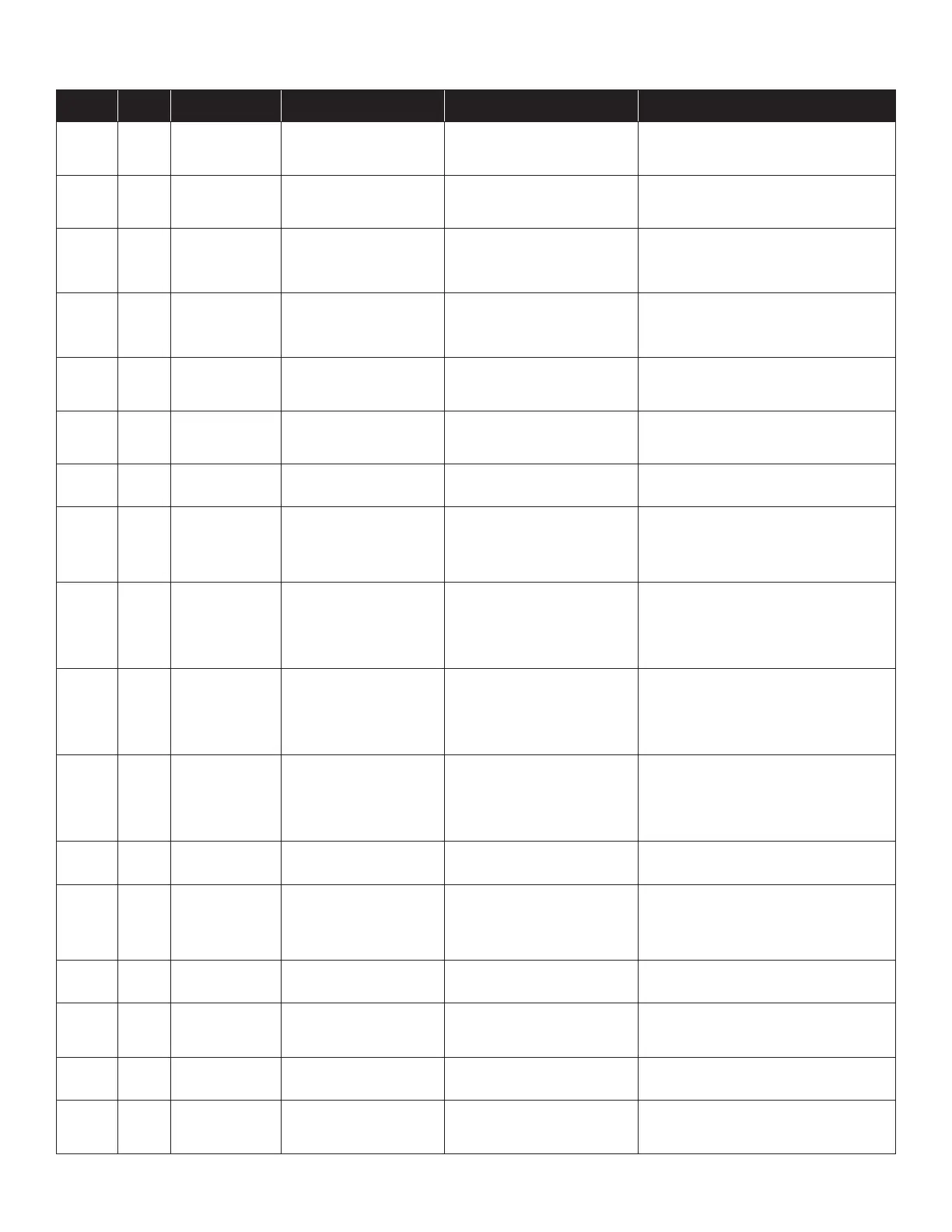

54 - EEV MINOR

This error indicates the equipment is

experiencing frequent low discharge

superheat faults.

Control has determined continued

operation is acceptable. This indi-

cates they may be a problem with the

equipment.

• Thermistors inoperable or improperly

connected

• Faulty indoor EEV or indoor EEV coil

• Faulty control board

• Check the connection to thermistors; Repair/replace if

needed

• Check indoor EEV; Replace if needed

• Check indoor EEV coil; Replace if needed

• Replace control board if necessary

55 - HI DIS TEMP MIN

This error indicates the equipment is

experiencing frequent high discharge

temperature faults. Control has

determined continued operation is

acceptable. This indicates they may

be a problem with the equipment.

• Discharge thermistor inoperable or improp-

erly connected

• Discharge thermistor is put in incorrect

position or off

• Low refrigerant charge

• Overcharge

• Faulty compressor

• Check discharge thermistor resistance and connections;

Repair/replace as needed

• Check discharge thermistor position

• Check refrigerant charge level; Adjust if needed

• Check the compressor; Repair/replace if needed

56 E56 SUCT TEMP FAIL

The control has detected if the

Outdoor Suction Temperature Sensor

is out of range.

• Suction thermistor inoperable or not prop-

erly connected

• Faulty reversing valve

• Check the connection to suction thermistor; Repair/re-

place if needed

• Check reversing valve; Replace if needed

57 - CL LOOP SWEAT

This indicates the control is sensing

sweating on the cooling loop.

<3.5 - 5.0 ton only>

• Refrigerant Leak

• Low refrigerant charge

• Faulty indoor EEV or indoor EEV coil

• Thermistors inoperable or improperly

connection

• Test for system leaks using leak test procedure

• Check refrigerant charge level; Adjust if needed

• Check indoor EEV; Replace if needed

• Check indoor EEV coil; Replace if needed

• Check the connection to thermistors; Repair/replace if

needed

58 E58 OL OPEN

The Overload Protection sensor for

Compressor is opened.

• Overload protection (OL) sensor inoper-

able

• Check resistance on OL sensor to verify operation;

Replace if needed.

• Check OL sensor position on compressor body.

59 E59 RV FAIL

This indicates the equipment is expe-

riencing reversing valve faults.

• Faulty reversing valve body or coil

• Low refrigerant charge

• Faulty pressure sensor

• Faulty control board

• Check reversing valve body or coil; Replace if needed

• Check refrigerant charge level; Adjust if needed

• Check pressure sensor; Replace if needed

• Replace control board if necessary

60 E60

NO HP HEAT

(WARM UP)

No heat pump heating.

Need warming up on compressor to

run properly.

• Need 2 hour power ON.

• Need heat up on compressor motor/oil.

• Wait for 2 hours after turn-on power on Outdoor unit.

• Use secondary heat source.

B0 Eb0 NO ID AIRFLOW

The estimated airow from indoor

subsystem is near to 0 CFM.

• Failed indoor blower motor

• Indoor fan motor not properly connected

• Too much static pressure

• Check ID fan motor wiring and connectors; Repair/replace

if needed

• Check ID fan motor; Replace if needed

• Check the obstruction inside duct work.

Loading...

Loading...