FC 300 Operating Instructions

How to Install

" Electrical Installation

NB!:

Cables General

All cabling must comply with national and local regulations on cable cross-sections and

ambient temperature. Copper (60/75°C) conductors recom me n ded.

Aluminium C onductors

Aluminium conductors are not recommended.

Terminals can accept aluminium co nductors but th e

conductor surface has to be clean and the oxidation

must be removed and sealed by neutal acid free

Vaseline grease before the conductor is connected.

Furthermore the terminal screw must be retightened

after two days due to softness of the aluminium. It

is crucial to keep the connection a gas tight joint,

otherwise the aluminium surface will oxidize again.

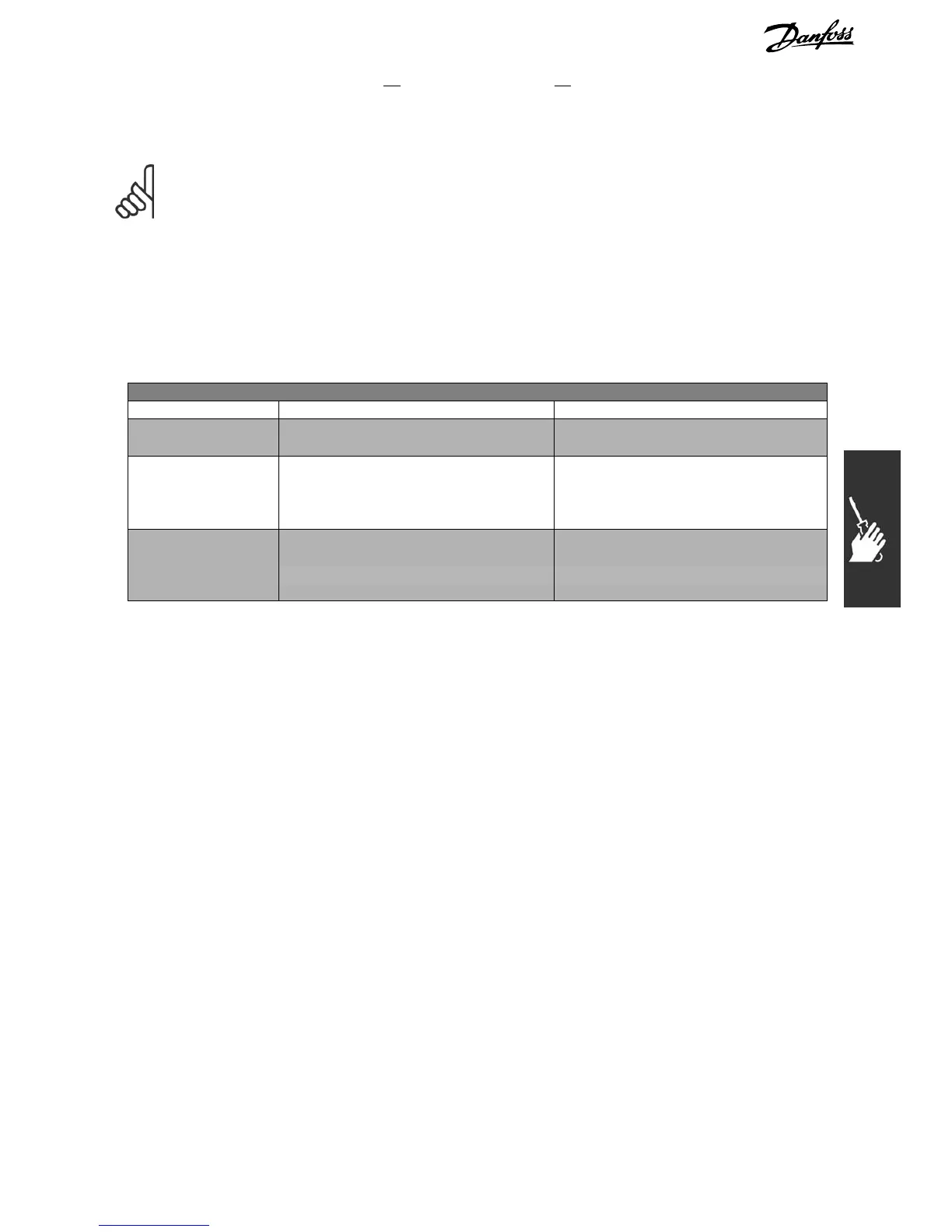

Tightening-up Torque

FC size Cable for: Tightening up torque

0.25-7.5 kW (A1, A2,

A3 and A5)

Line, Brake resistor, load sharing, Motor

cables

0.5-0.6 Nm

Line, Brake resistor, load sharing, Motor

cables

1.8 Nm

Relay 0.5-0.6 Nm

11-15 kW (B1)

Earth 2-3 Nm

Line, Brake resistor, loa d sharing cables 1.8 Nm

Motor cables 1.8 Nm

Relay 0.5-0.6 Nm

18.5-22 kW (B2)

Earth 2-3 Nm

" Removal o f

Knockouts for Extra Cables

1. Remove cable entry from the frequency converter (Avoiding foreign parts falling into

the frequency converter when removing knockouts)

2. Cable e

ntry has to be supported around the k nockout you intend to remove.

3. The knockout can now be removed with a strong mandrel and a hammer.

4. Remove burrs from the hole.

5. Mount Cabl

e entry on frequency converter.

17

MG.33.A7.02 - VLT is a registered Danfoss trademark

Loading...

Loading...