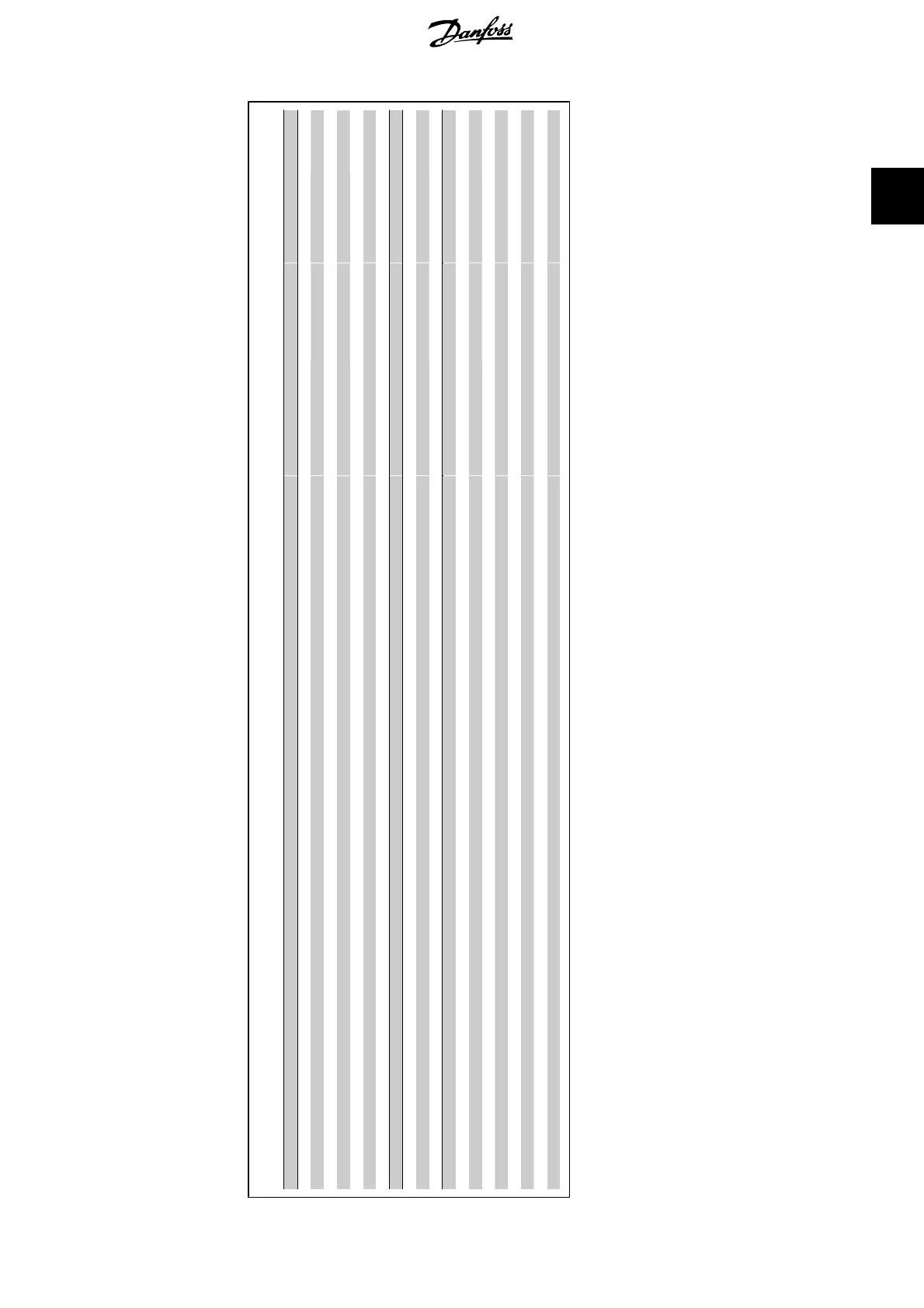

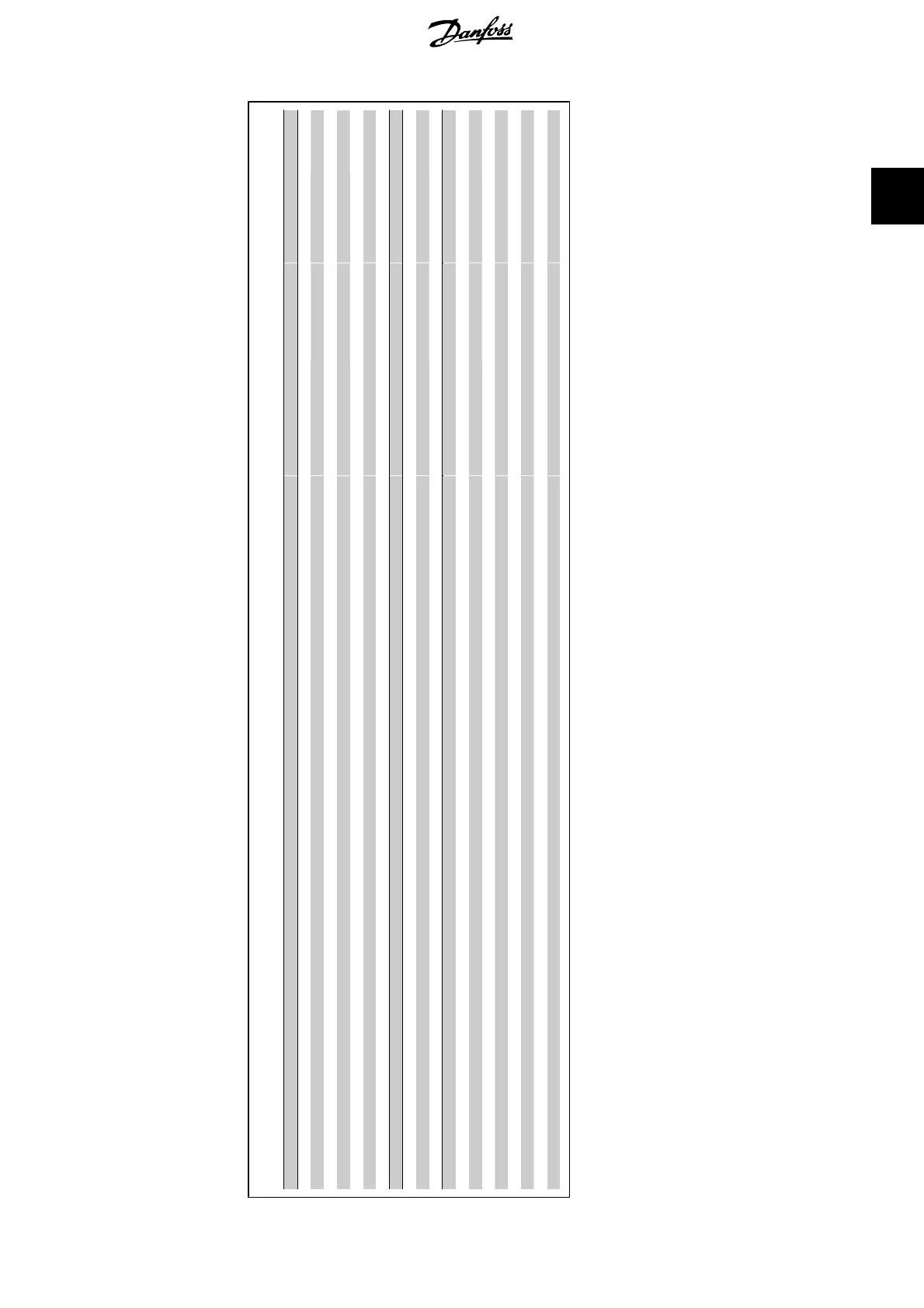

Par. No. # Parameter description Default value 4-set-up FC 302

only

Change during op-

eration

Conver-

sion index

Type

7-0* Speed PID Ctrl.

7-00 Speed PID Feedback Source null All set-ups FALSE - Uint8

7-02 Speed PID Proportional Gain ExpressionLimit All set-ups TRUE -3 Uint16

7-03 Speed PID Integral Time ExpressionLimit All set-ups TRUE -4 Uint32

7-04 Speed PID Differentiation Time ExpressionLimit All set-ups TRUE -4 Uint16

7-05 Speed PID Diff. Gain Limit 5.0 N/A All set-ups TRUE -1 Uint16

7-06 Speed PID Lowpass Filter Time 10.0 ms All set-ups TRUE -4 Uint16

7-08

Speed PID Feed Forward Factor 0 % All set-ups FALSE 0 Uint16

7-2* Process Ctrl. Feedb

7-20 Process CL Feedback 1 Resource [0] No function All set-ups TRUE - Uint8

7-22 Process CL Feedback 2 Resource [0] No function All set-ups TRUE - Uint8

7-3* Process PID Ctrl.

7-30 Process PID Normal/ Inverse Control [0] Normal All set-ups TRUE - Uint8

7-31 Process PID Anti Windup [1] On All set-ups TRUE - Uint8

7-32 Process PID Start Speed 0 RPM All set-ups TRUE 67 Uint16

7-33 Process PID Proportional Gain 0.01 N/A All set-ups TRUE -2 Uint16

7-34 Process PID Integral Time 10000.00 s All set-ups TRUE -2 Uint32

7-35 Process PID Differentiation Time 0.00 s All set-ups TRUE -2 Uint16

7-36 Process PID Diff. Gain Limit 5.0 N/A All set-ups TRUE -1 Uint16

7-38 Process PID Feed Forward Factor 0 % All set-ups TRUE 0 Uint16

7-39 On Reference Bandwidth 5 % All set-ups TRUE 0 Uint8

2.19.8. 7-** Controllers

FC 300 Programming Guide 2. How to Programme

MG.33.M2.02 - VLT

®

is a registered Danfoss trademark

213

2

Loading...

Loading...