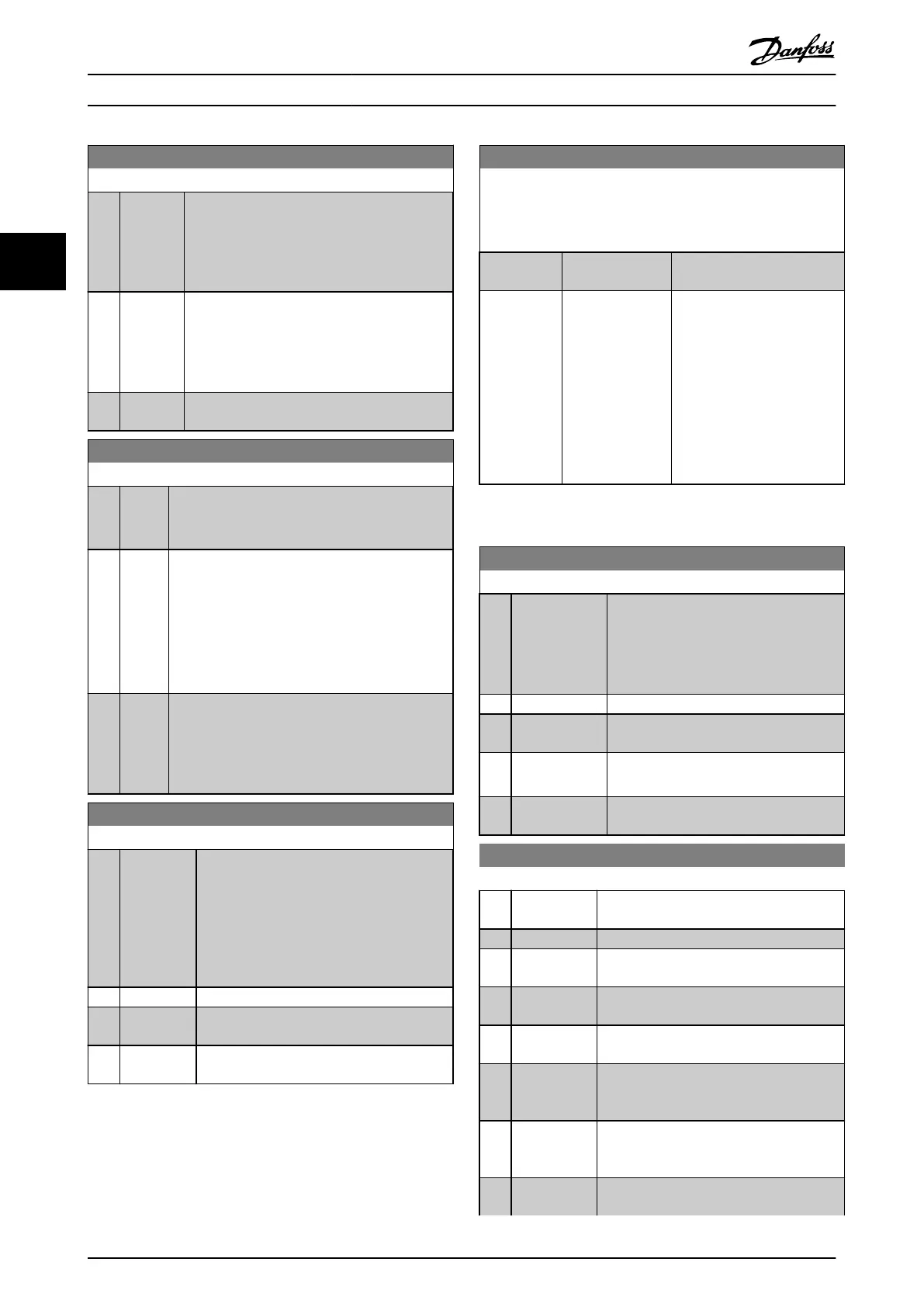

8-05 End-of-Timeout Function

Option: Function:

•

[7] Set-up 1.

•

[8] Set-up 2.

•

[9] Set-up 3.

•

[10] Set-up 4.

[0] Hold set-

up

Retains the set-up selected in

parameter 8-04 Control Timeout Function and

displays a warning, until parameter 8-06 Reset

Control Timeout toggles. Then the frequency

converter resumes its original set-up.

[1] * Resume

set-up

Resumes the set-up active before the time-out.

8-06 Reset Control Timeout

Option: Function:

This parameter is active only when option [0] Hold

set-up has been selected in parameter 8-05 End-of-

Timeout Function.

[0] * Do not

reset

Retains the set-up specied in

parameter 8-04 Control Timeout Function:

•

[7] Set-up 1

•

[8] Set-up 2

•

[9] Set-up 3

•

[10] Set-up 4

[1] Do

reset

Returns the frequency converter to the original

set-up following a control word timeout. When the

value is set to [1] Do reset, the frequency converter

performs the reset and immediately reverts to the

[0] Do not reset setting.

8-07 Diagnosis Trigger

Option: Function:

Select [0] Disable to send no extended

diagnosis data (EDD). Select [1] Trigger on

alarms to send EDD upon alarms or [2] Trigger

alarm/warn. to send EDD upon alarms, or

warnings. Not all eldbusses support the

diagnosis functions. This parameter has no

function for BACnet.

[0] * Disable

[1] Trigger on

alarms

[2] Trigger

alarm/warn.

8-08 Readout Filtering

If the speed feedback value readouts on eldbus are uctuating,

this function is used. Select ltered, if the function is required. A

power cycle is required for changes to take eect.

Option: Function:

[0] Motor Data Std-

Filt.

Normal bus readouts.

[1] Motor Data LP-

Filter

Filtered bus readouts of the

following parameters:

16-10 Power [kW]

16-11 Power [hp]

16-12 Motor Voltage

16-14 Motor current

16-16 Torque [Nm]

16-17 Speed [RPM]

16-22 Torque [%]

16-25 Torque [Nm] High

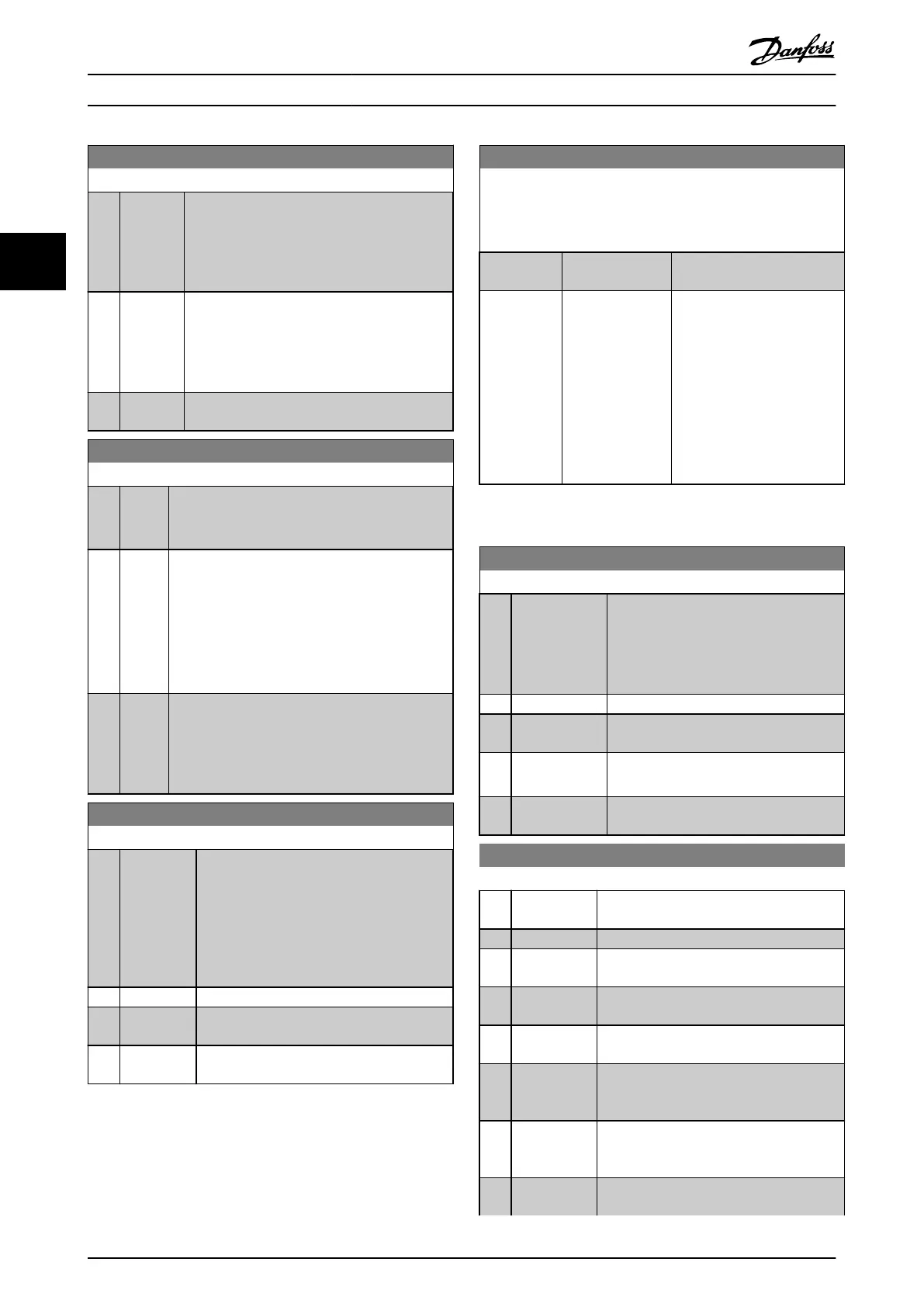

3.9.2 8-1* Ctrl. Word Settings

8-10 Control Prole

Option: Function:

Select the interpretation of the control

and status words corresponding to the

installed eldbus. Only the selections valid

for the eldbus installed in slot A are

visible in the LPC display.

[0] * FC prole

[1] PROFIdrive

prole

[5] ODVA Available only with MCA 104 DeviceNet,

MCA 121 Ethernet/IP.

[7] CANopen DSP

402

8-13 Congurable Status Word STW

Option: Function:

This parameter enables conguration of bits

12–15 in the status word.

[0] No function

[1] * Prole Default Function corresponds to the prole default

selected in parameter 8-10 Control Prole.

[2] Alarm 68

Only

Only set in case of an Alarm 68.

[3] Trip excl.

Alarm 68

Set in case of a trip, except if Alarm 68

executes the trip.

[10] T18 DI status. The bit indicates the status of terminal 18.

0 indicates that the terminal is low.

1 indicates that the terminal is high.

[11] T19 DI status. The bit indicates the status of terminal 19.

0 indicates that the terminal is low.

1 indicates that the terminal is high.

[12] T27 DI status. The bit indicates the status of terminal 27.

0 indicates that the terminal is low.

Parameter Descriptions

VLT

®

HVAC Drive FC 102

90 Danfoss A/S © 03/2015 All rights reserved. MG11CE02

33

Loading...

Loading...