CAN (Controller Area Network) Ports

System Design

All PLUS+1 modules have CAN ports that conform to CAN 2.0B specifications, including CAN shield.

The second (CAN1) port on MC050-010/012 and MC050-020/022 controllers may not interface with the

PLUS+1 Service Tool, depending on the version of .hwd file used to build the application.

MC050-010/012 .hwd files version 190 and higher allow communication with the PLUS+1 Service Tool.

MC050-020/022 .hwd files version 150 and higher allow communication with the PLUS+1 Service Tool.

Regardless of .hwd version, CAN1 port and CAN2 port on MC050-055/05B controllers cannot be used to

download GUIDE application programs.

Warning

Unintended movement of the machine or mechanism may cause injury to the technician or bystanders.

Machine performance may be impaired if CAN communications are disrupted by electrical fields in excess

of 30 V/m between 20 and 30 MHz. To prevent potential unintended machine movement and to meet

EMC requirements, a shielded CAN bus must be used to achieve 100 V/m immunity.

Terminating Resistor

Each end of the main backbone of the CAN bus must be terminated with an appropriate resistance to

provide correct termination of the CAN_H and CAN_L conductors. This termination resistance should be

connected between the CAN_H and CAN_L conductors.

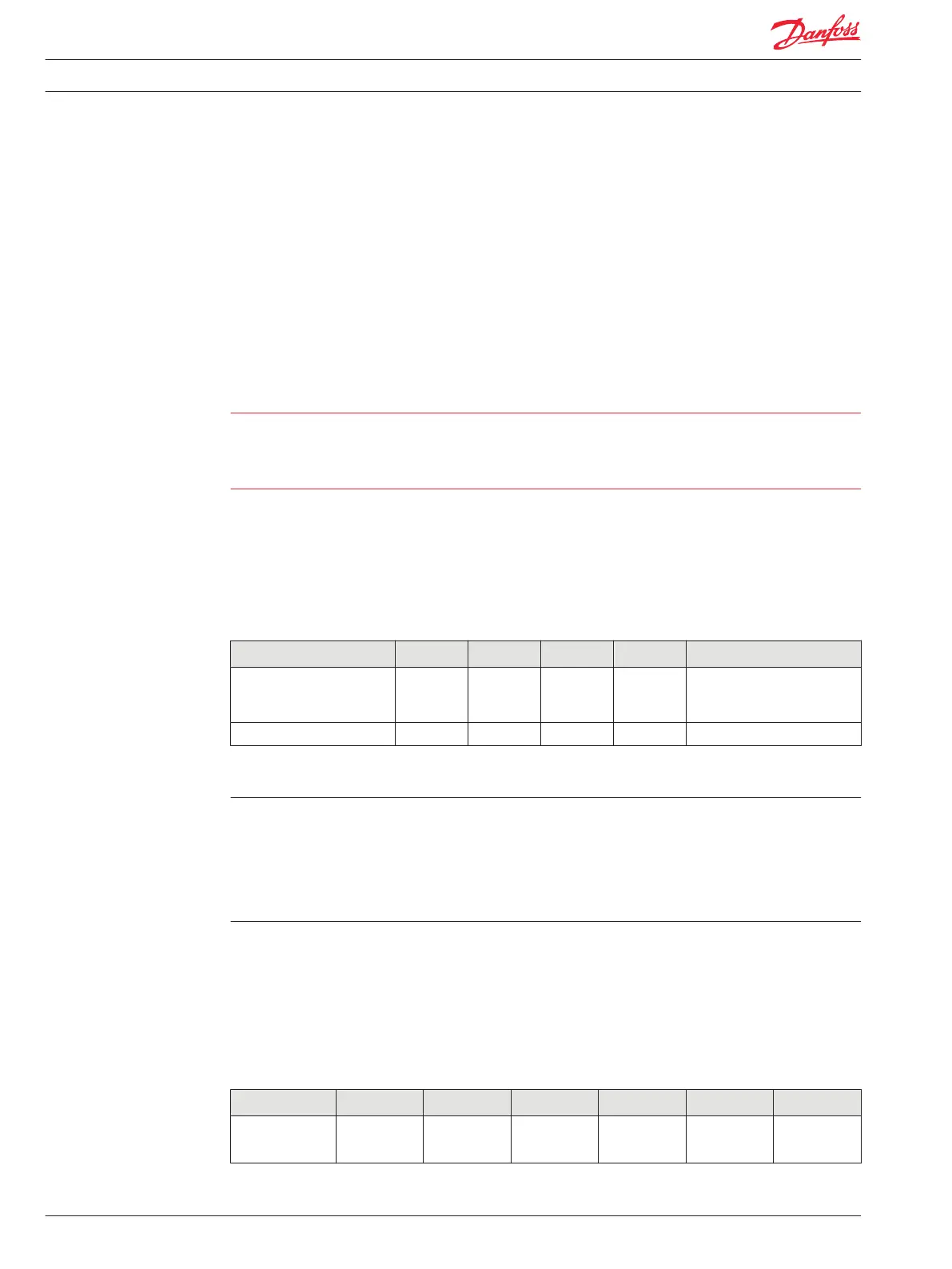

Specifications

Description Units Minimum Maximum Nominal Comment

Resistance Ω 110 130 120 Minimum power dissipation

400 mW (assumes a short of 16

Vdc to CAN_H).

Inductance µH 1

CAN Bus Installation

Total bus impedance should be 60 Ω.

The CAN transceiver will be damaged by any voltage outside of allowable range, (-7 to +36 Vdc), even

with a very short pulse.

If using shielded cable, the shield must be grounded to the machine ground at one point only; preferably

at the mid-point of the CAN bus. Each PLUS+1 module CAN shield pin must be connected to the cable

shield.

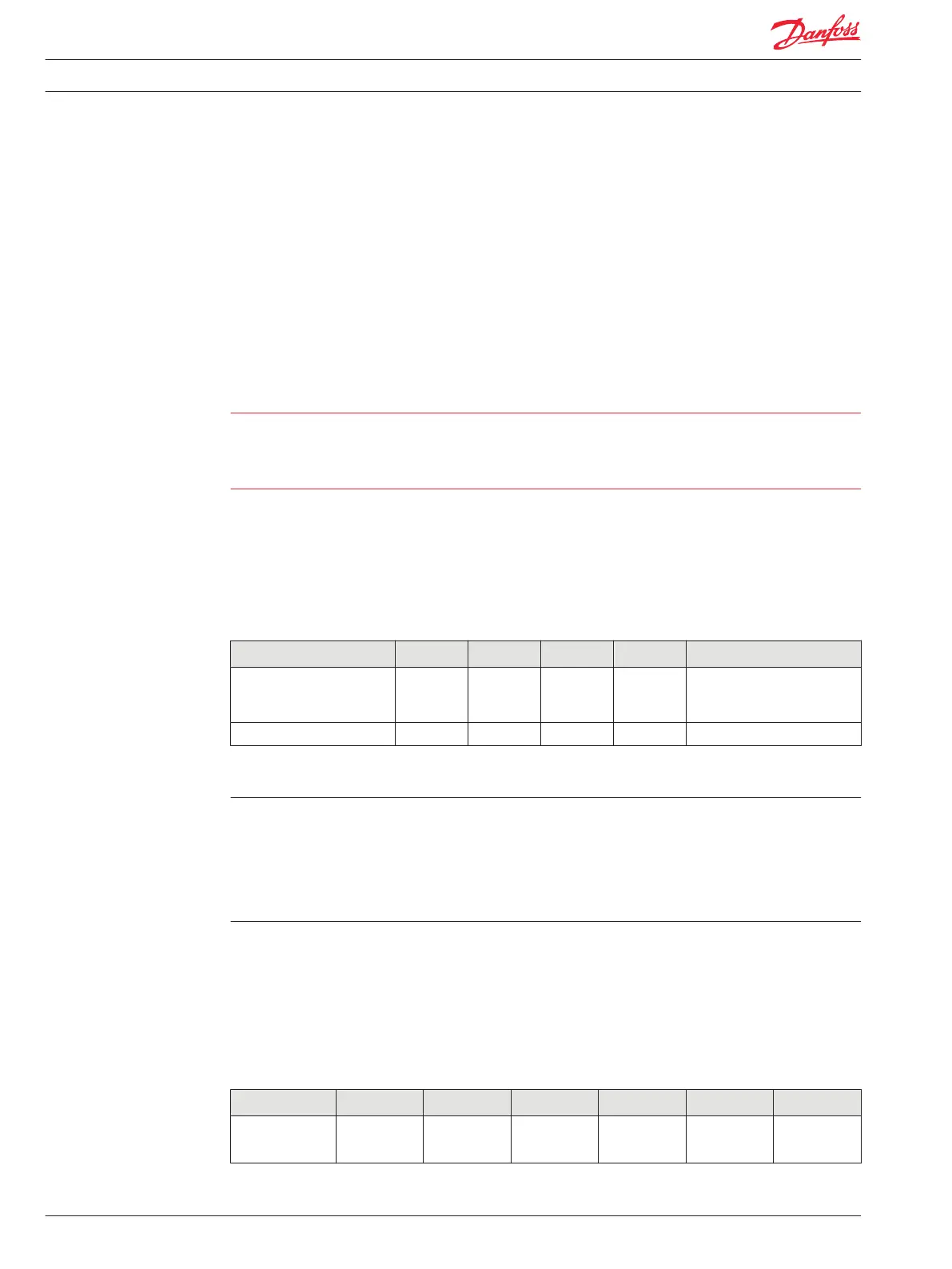

Expansion Module CAN Bus Loading

System designers incorporating PLUS+1 expansion modules in their applications should be aware of

PLUS+1 CAN bus loading and controller memory usage during system design. Each expansion module is

associated with a PLUS+1 controller and uses part of the controller’s memory resources for inter-module

communications. The table below can be used to estimate system CAN bus loading and the memory

impact of I/O modules on their associated controller.

Estimated Usage of Memory and Communication Resources

Description IX012-010 IX024-010 OX012-010 OX024-010 IOX012-010 IOX024-20

Estimated

module bus load

(using default

4% 10% 11% 27% 11% 27%

Technical Information PLUS+1® Controller Family

Controller Area Network Specifications

20 520L0719 • Rev PB • Feb 2014

Loading...

Loading...