22 of 114

M-AP-001-EN Rev. Q

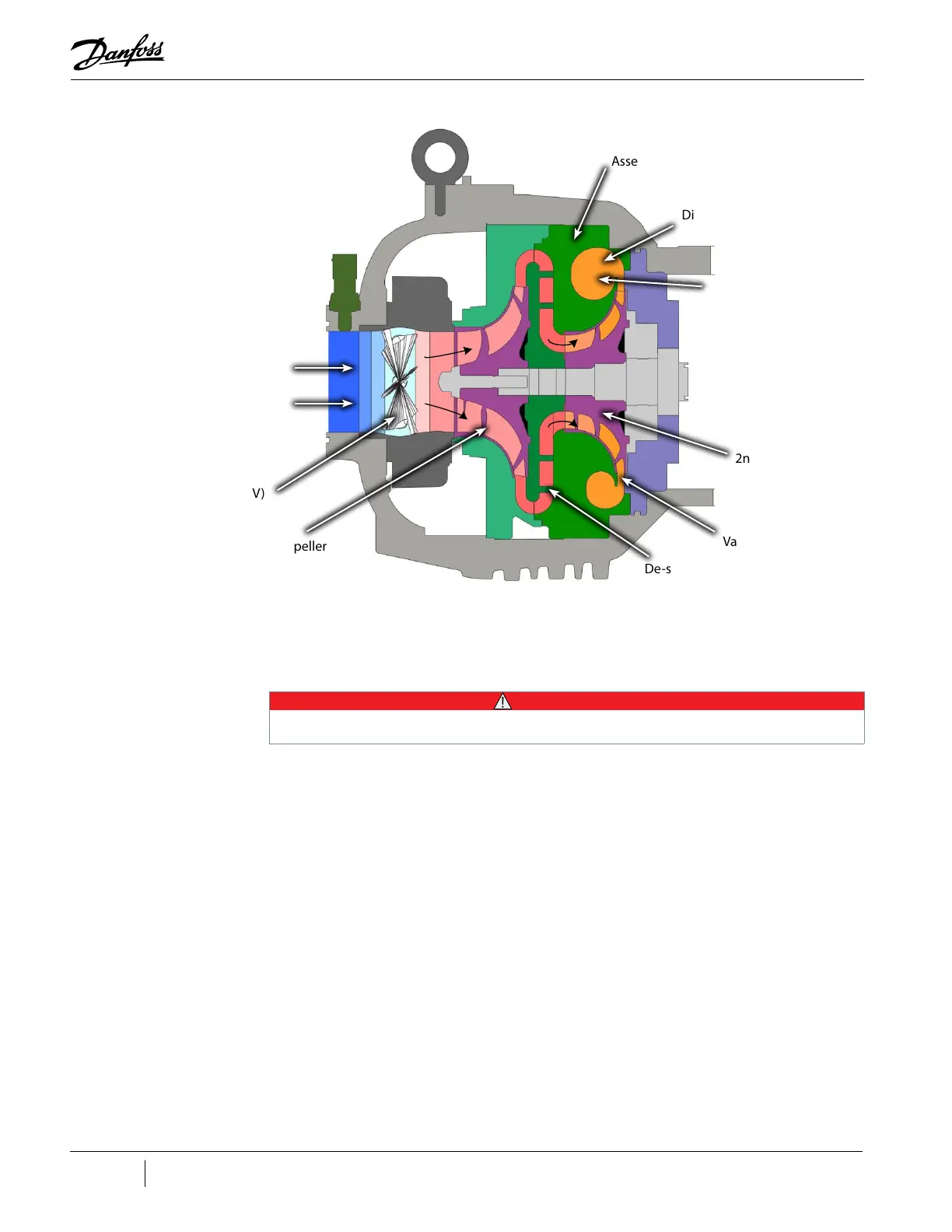

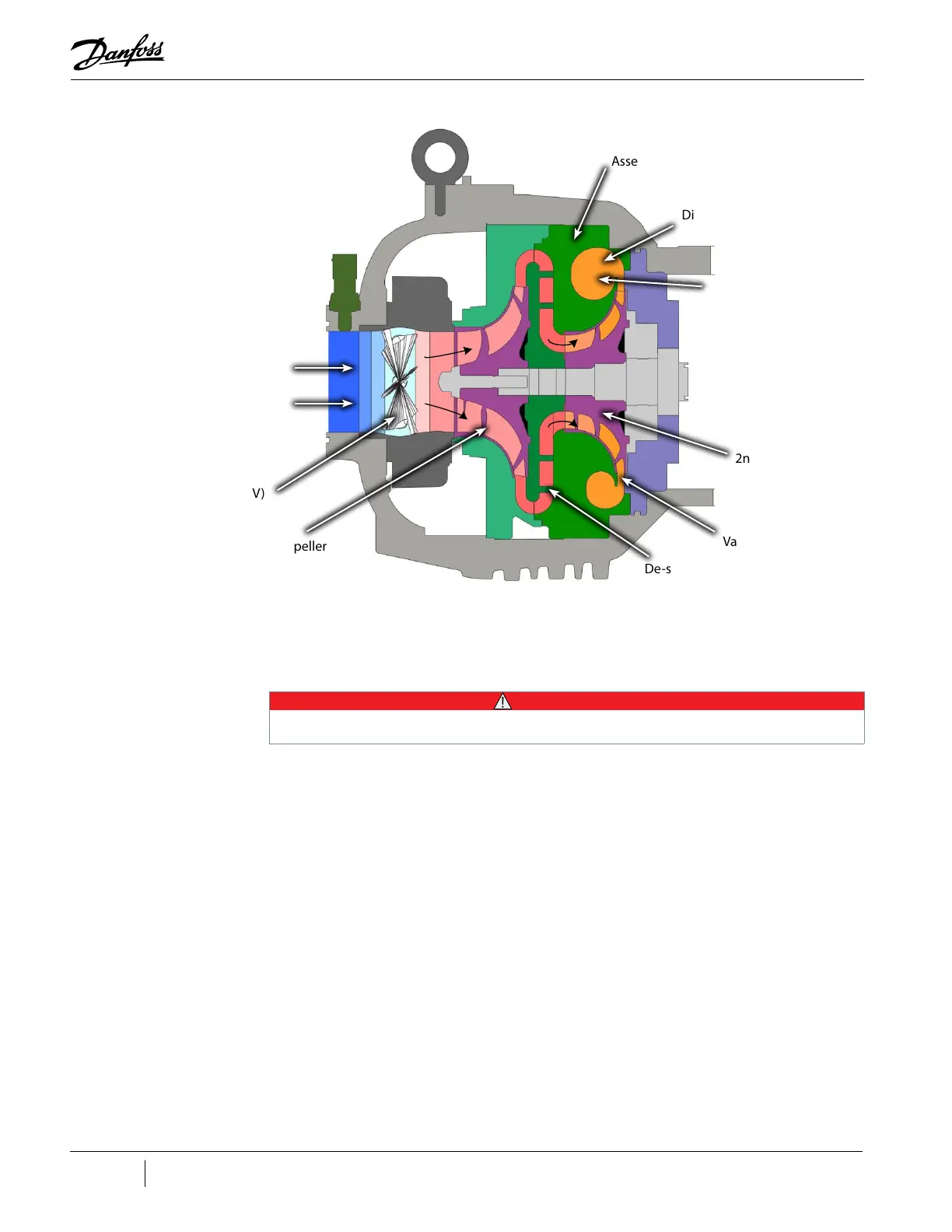

Figure 3-2 Compressor Fluid Path (TGS310, TTS350, TGS390, TGS490, TTS400, TGS520, and TTS700)

3.2 Motor Cooling

Liquid refrigerant is channeled at full condenser pressure from the main liquid line to the compressor

to cool the electronic, mechanical, and electromechanical components (refer to "Figure 3-3

Compressor Cooling Circuit (TGS230 / TTS300)" and "Figure 3-4 Compressor Cooling Circuit (TTS300

Split-Cooling, TGS310, TTS350, TGS390, TGS490, TTS400, TT700, and TGS520)".

• • • CAUTION • • •

A minimum operating pressure ratio of 1.5 is required to maintain adequate cooling of the compressor.

The sub-cooled refrigerant enters the compressor through two solenoid valves and associated fixed

orifices located behind the service access cover. The orifices cause the refrigerant to expand, thereby

lowering its temperature. Both valves open in response to the temperature sensed in the motor and

inverter.

From the outlet of the orifices, the refrigerant is directed to the heatsink plate of the inverter and to

the underside of the SCR heatsink. The refrigerant also passes through grooves surrounding the motor

stator. As the refrigerant flows through the grooves, it vaporizes into a gas. At the coil outlet, the

refrigerant gas is channeled back to the suction inlet via the motor cavity, thereby cooling the rotor.

All models with the exception of the TTS300 and TGS230 use a split-cooling method where the motor

and electronics portions are cooled separately by refrigerant liquid.

Inlet Guide Vanes (IGV)

1st Stage Impeller

De-swirl Vanes

Vaneless Diffuser

2nd Stage Impeller

Discharge Port

Volute

Assembly

Low - Pressure / Low -

Temperature Gas

High - Pressure /

High - Temperature

Gas

Loading...

Loading...