29 of 114M-AP-001-EN Rev. Q

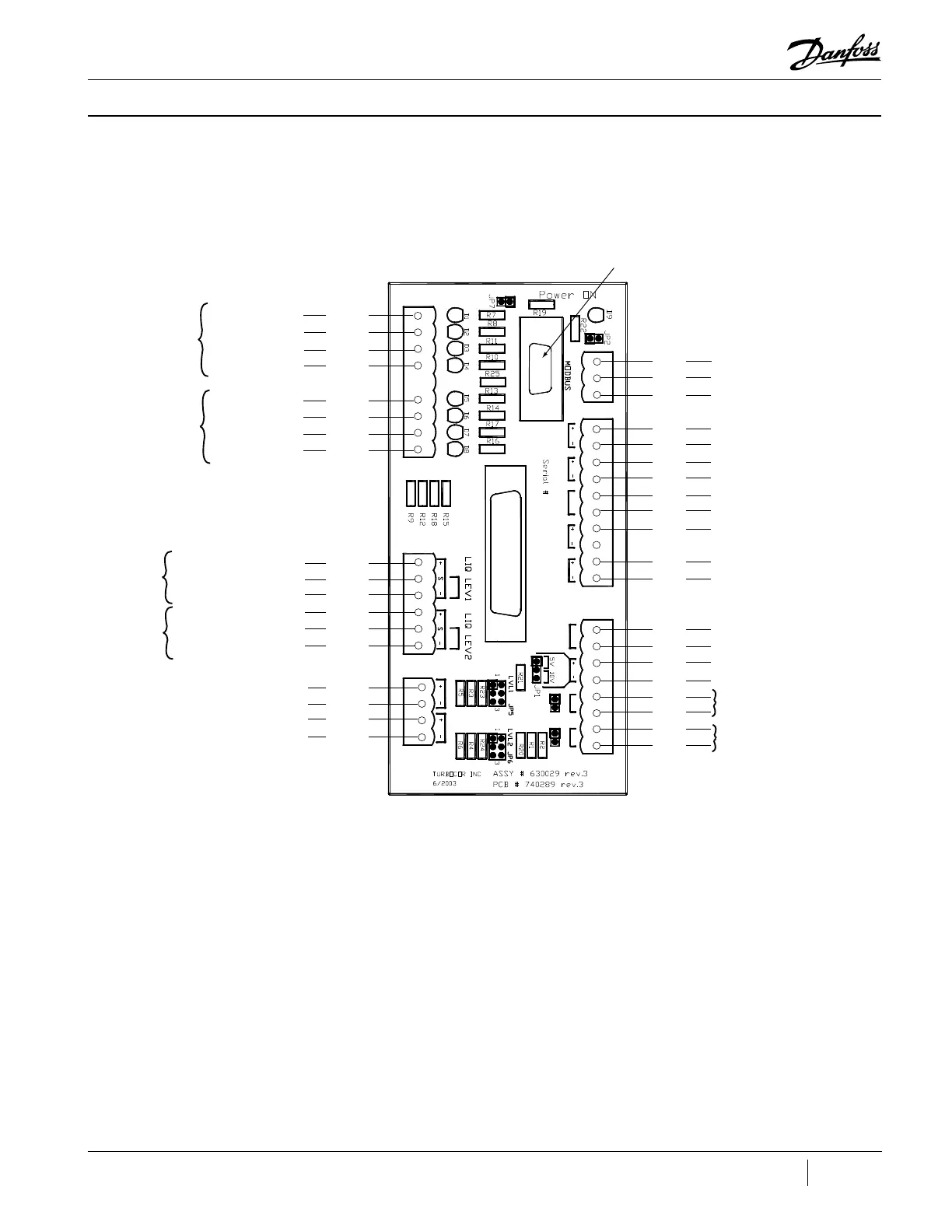

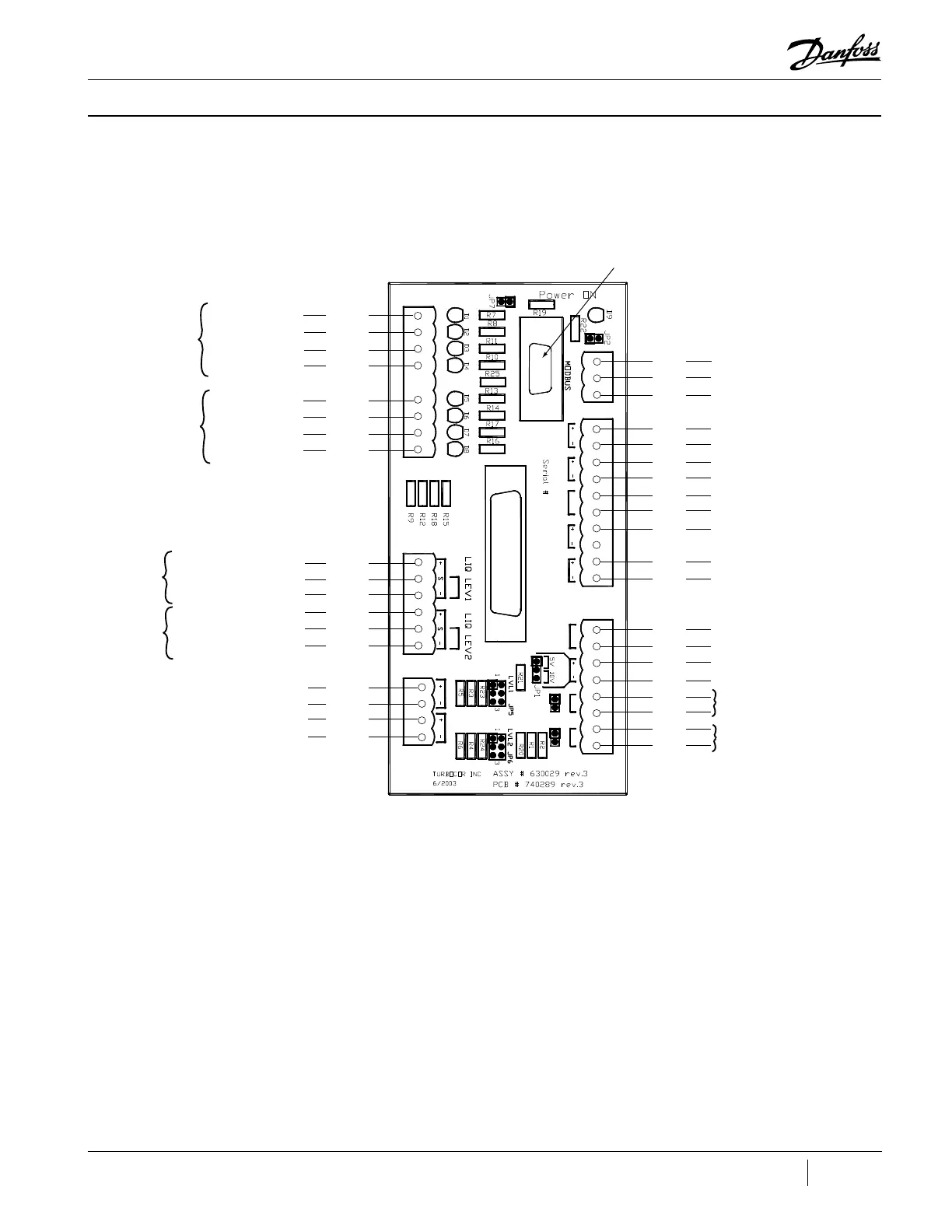

Chapter 4.0 Control Interface Wiring

The Compressor I/O Board is the entry point for control wiring from the chiller/plant to the

compressor. Refer to Figures 4-1 and 4-2 for the proper Compressor I/O Board connectivity.

Figure 4-1 Typical Control Wiring

OUT

I/O

I/O

IN

IN

IN

IN

OUT

OUT

OUT

OUT

IN

IN

OUT

OUT

OUT

OUT

IN

IN

IN

IN

ModBus Common (Shield)

ModBus RS-485 NetB

ModBus RS-485 NetA

Demand + 0-10V

Demand -

Interlock Contact - Safety N/C

Interlock Contact - Safety N/C

Compressor Status - N/O Contact

Compressor Status - N/O Contact

Entering Chilled Water

Temp. Sensor

Leaving Chilled Water

Temp. Sensor

EXV Phase 1A

EXV Phase 1B

EXV Phase 2A

EXV Phase 2B

EXV #1

(Evaporator or

load balancing

valve)

EXV Phase 1A

EXV Phase 1B

EXV Phase 2A

EXV Phase 2B

EXV #2

(Economizer or

load balancing

valve)

Level Sensor +15V

Sensor Signal , 1-5Volts

Level Sensor 0V

Level Sensor +15V

Sensor Signal , 1-5Volts

Level Sensor 0V

Level

Sensor

#1 (Evaporator)

Level

Sensor

#2 (Economizer)

Liquid Temperature +

Liquid Temperature -

Compressor Running - N/O Contact

Compressor Running - N/O Contact

Pressure Sensor Signal, 1-5Volts

Sensor +5V

Sensor 0V

Temperature Sensor Signal, 1-5Volts

*Universal Analog Output +

*Universal Analog Output -

* Universal output can be used for :

output manual control

0-5VDC or 0-10VDC

RS232 Monitoring Connector (DB9)

J6

J7

J1

J2

J4 J5

J3

J8

LIQDT

SPEED

STATUSI/LOCK

DEMAND

COM

NETA

NETB

EXV1

EXV2

1A 1B 2A 2B 1A 1B 2A 2B

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

IN

IN

IN

OUT

IN

OUT

RUN

ENTRY LEAVE

ANALOG

Float

Float

SPARE T SPARE P

No function

No function

**Level sensor circuit can be congured

for two types of sensors using jumpers

JP5 and JP6. Refer to the Installation and

Operations Manual for details.

Loading...

Loading...