28 of 114

M-AP-001-EN Rev. Q

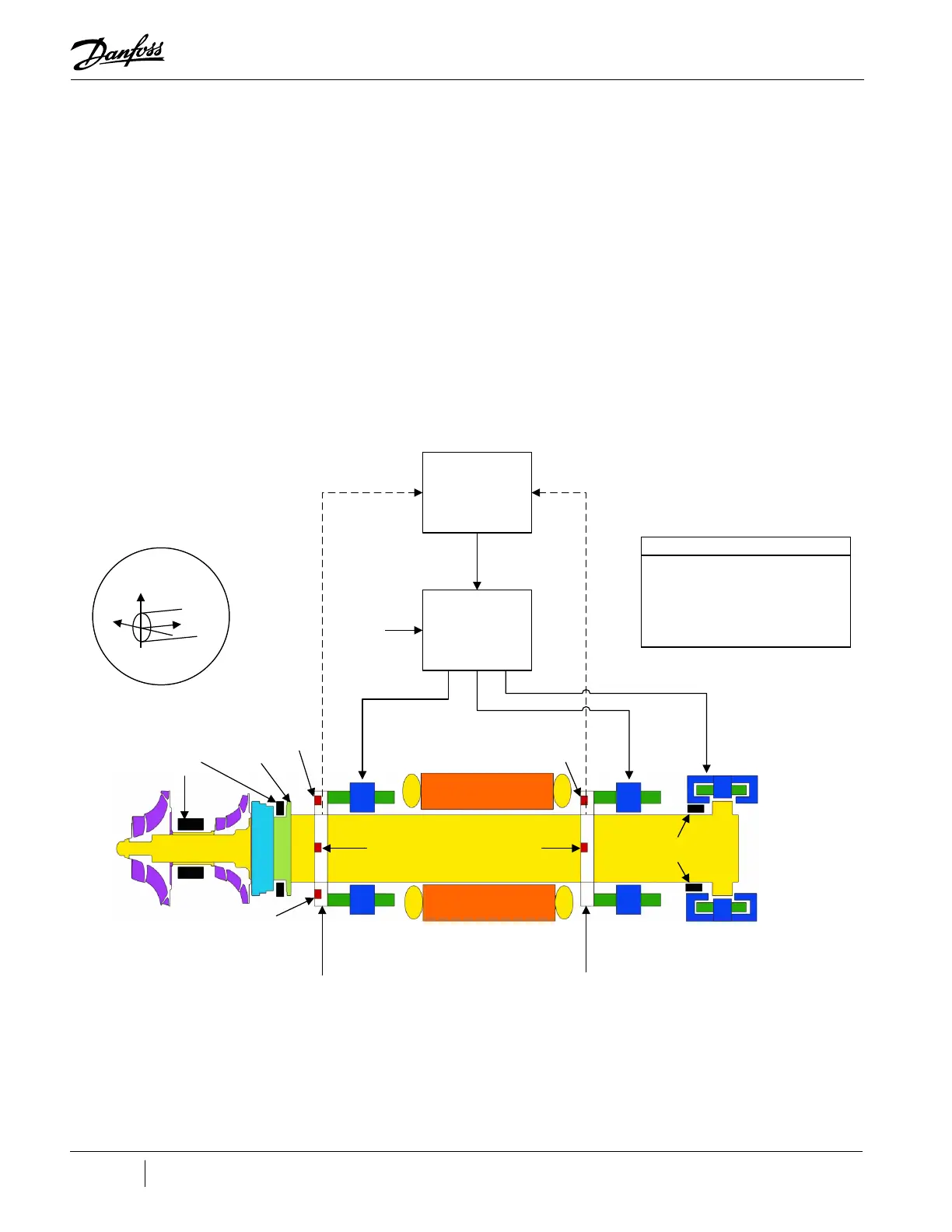

3.5.2 Bearing Control System

The Bearing Control System uses rotor position feedback to close the loop and maintain the rotor

in the correct running position (refer to "Figure 3-8 Magnetic Bearing Control System"). The Bearing

Controller issues position commands to the Bearing PWM Amplifier. The position commands consist

of five channels with each channel allocated to one of the five bearing actuator coils (one coil for each

axis). The amplifier uses Inverter technology to convert the low-voltage position commands to the

250VDC PWM signals that are applied to each bearing actuator coil.

Rotor position sensors are located on rings attached to the front and rear radial bearing assemblies.

The front sensor ring contains sensors that read the rotor position along the X, Y, and Z axes. The rotor

position along the Z (or axial) axis is read by measuring the distance between the sensor and a target

sleeve mounted on the rotor. The rear sensor ring contains sensors that read the position along the X

and Y axes. Information from the position sensors is continuously fed back to the bearing controller.

Figure 3-8 Magnetic Bearing Control System

Impellers

Z-axis

Position

S en so r

S en so r Ring

Front

Rad ial

Bearing

Motor

S en so r Ring

R ea r

Rad ial

Bearing

Axial

Bearing

X-axis

Position

S en so r

X-axis

Posi tion

S en so r

Touchdown

Bearings

Touchdown

Bearings

Target

Sleeve

Y-axis

Position

S en so r

Y-axis

Position

S en so r

Channels

Fx, Fy

Channels

Rx, Ry

Channel Axi

250 VDC

Position Command

Signals

Bearing-Mo tor-

Co mpressor

Controller (BMCC)

Bearing

PWM

Amplifier

Position FeedbackPosition Feedback

Axi s Bea ri ng Channel

X Front Radial Fx

Y Front Radial Fy

X Rear Radial Rx

Y Rear Radial Ry

Z Axi a l Axi

Shaft axes monitored

by position sensors

Y

X

Z

Shaft

Y

X

Z

Shaft

Loading...

Loading...