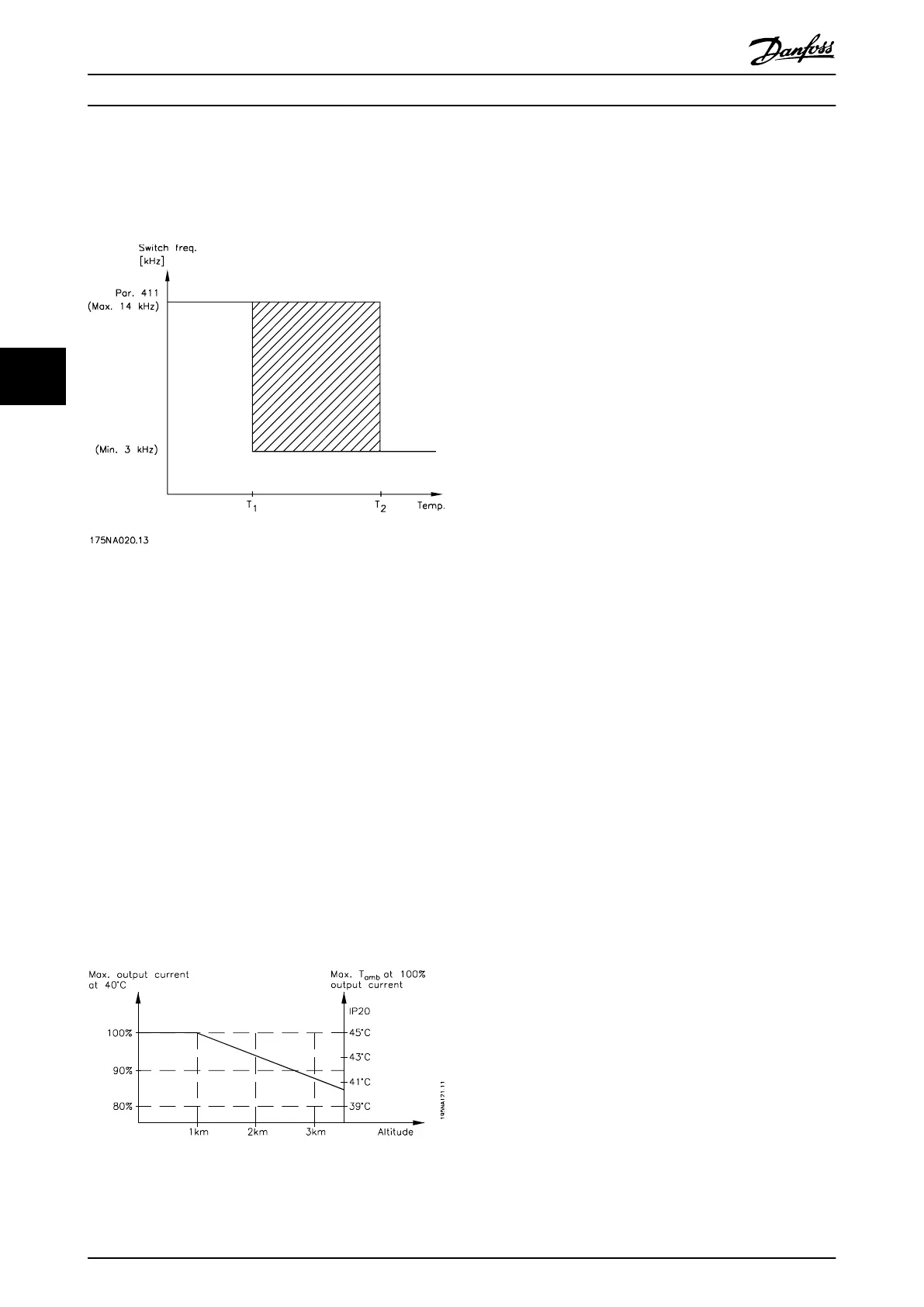

The function ensures that the frequency converter

automatically adjusts the switching frequency between f

sw,

min

and f

sw, max

(parameter 411 Switching frequency), as

shown in Illustration 5.2.

Illustration 5.2 Switching Frequencies vs. Temperature

When an LC filter is used, the minimum switching

frequency is 4.5 kHz.

5.1.10

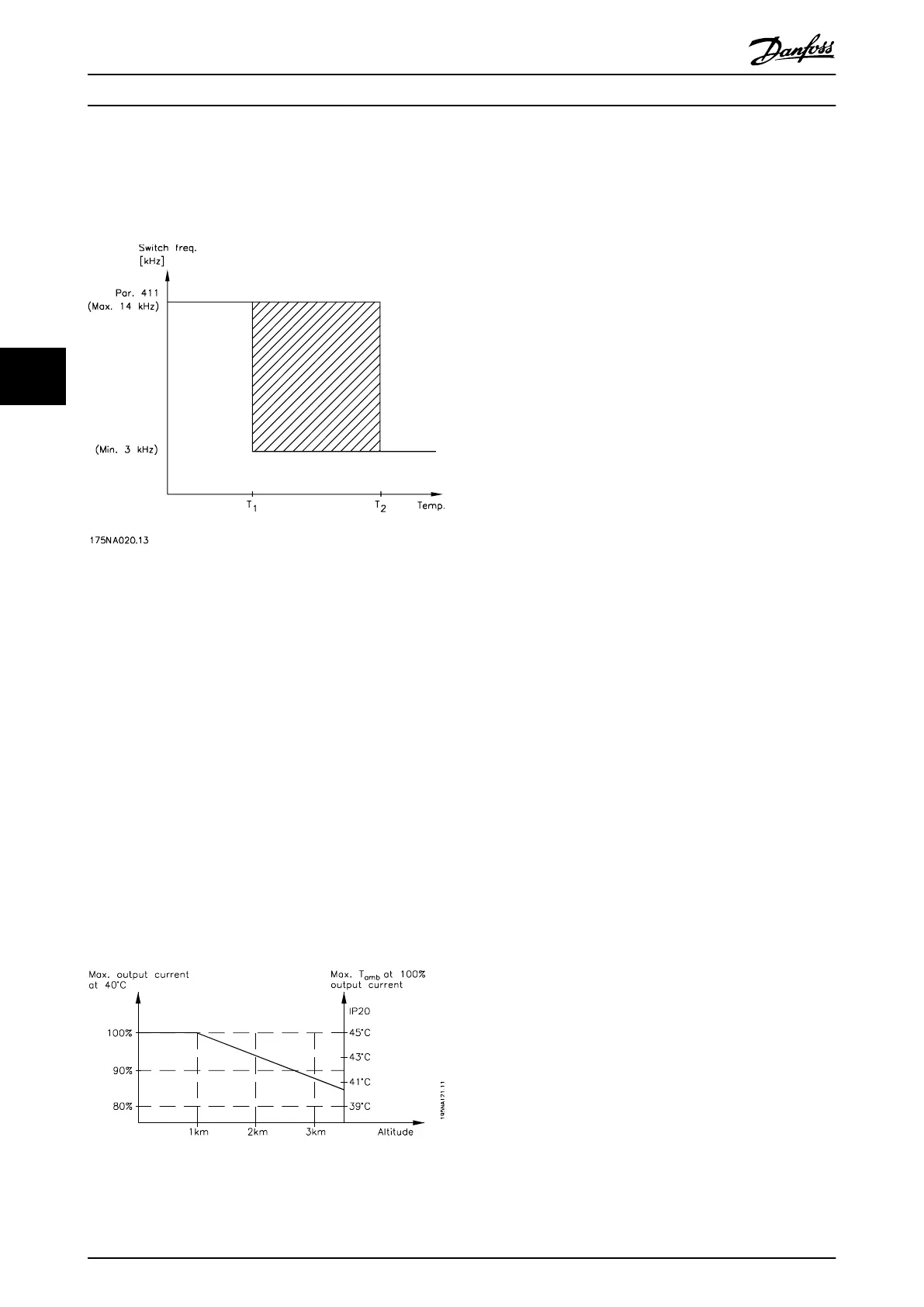

Derating for Air Pressure

Protective Extra Low Voltage (PELV) requirements stated in

IEC 61800-5-1 are not fulfilled at altitudes above 2000 m

(6562 ft.). Contact Danfoss for further information.

Below 1000 m derating is not necessary.

Above 1000 m, derate the ambient temperature (T

AMB

) or

maximum output current (I

MAX

) in accordance with the

diagram in Illustration 5.3:

1. Derating of output current versus altitude at

T

AMB

=maximum 45 °C.

2. Derating of max. T

AMB

versus altitude at 100%

output current.

Illustration 5.3 Derating for Air Pressure

5.1.11 Derating for Running at Low Speed

When a motor is connected to a frequency converter, it is

necessary to ensure adequate cooling of the motor. At low

RPM values, the motor fan is not able to supply an

adequate volume of cooling air. This problem occurs when

the load torque is constant (for example, with a conveyor

belt) across the full regulating range. The reduced amount

of ventilation determines the permissible torque in

continuous operation. If the motor is to run continuously

at an RPM lower than half the rated value, extra cooling air

must be supplied to the motor. Instead of providing extra

cooling, reduce the motor load ratio by selecting a larger

motor. However, the design of the frequency converter

puts limits on the size of motors that can be connected to

the frequency converter.

5.1.12

Derating for Long Motor Cables

The frequency converter has been tested using a 75 m

unscreened/unarmoured cable and a 25 m screened/

armoured cable and has been designed to work using a

motor cable with a rated cross-section. If a cable with a

larger cross-section is required, reduce the output current

by 5% for each step the cable cross-section is increased.

(Increased cable cross-section leads to increased

capacitance to ground, and thus to an increased ground

leakage current).

5.1.13

Derating for High Switching

Frequency

A higher switching frequency (to be set in parameter 411

Switching frequency) leads to higher losses in the

electronics of the frequency converter.

VLT 2800 has a pulse pattern in which it is possible to set

the switching frequency from 3.0- 10.0/14.0 kHz.

The frequency converter automatically derates the rated

output current I

VLT,N,

when the switching frequency

exceeds 4.5 kHz.

In both cases, the reduction is carried out linearly, down to

60% of I

VLT,N

.

All about VLT 2800

Design Guide

130 Danfoss A/S © Rev. May/2014 All rights reserved. MG27E402

55

Loading...

Loading...