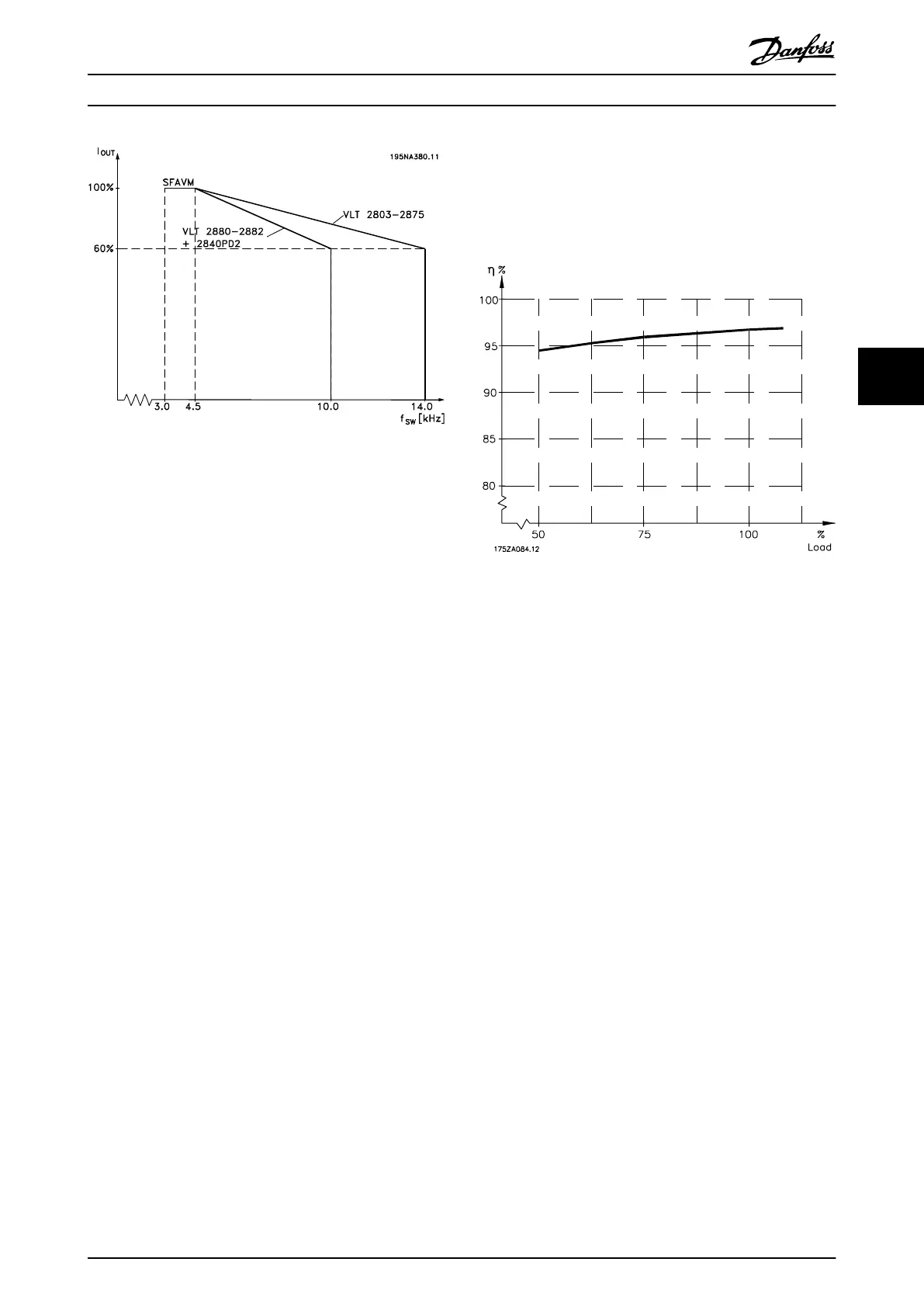

Illustration 5.4 Derating for High Switching Frequency

5.1.14

Vibration and Shock

The frequency converter has been tested according to a

procedure based on the following standards:

•

IEC 68-2-6: Vibration (sinusoidal) - 1970.

•

IEC 68-2-34: Random vibration broad-band -

general requirements.

•

IEC 68-2-35: Random vibration broad-band - high

reproducibility.

•

IEC 68-2-36: Random vibration broad-band -

medium reproducibility.

The frequency converter complies with requirements that

correspond to conditions when the unit is mounted on the

walls and floors of production premises, as well as in

panels bolted to walls or floors.

5.1.15

Air Humidity

The frequency converter has been designed to meet the

IEC 68-2-3 standard, EN 50178 item 9.4.2.2/ DIN 40040 class

E at 40 °C.

5.1.16

UL Standard

This device is UL-approved.

5.1.17

Efficiency

To reduce energy consumption it is important to optimise

the efficiency of a system. The efficiency of each single

element in the system should be as high as possible.

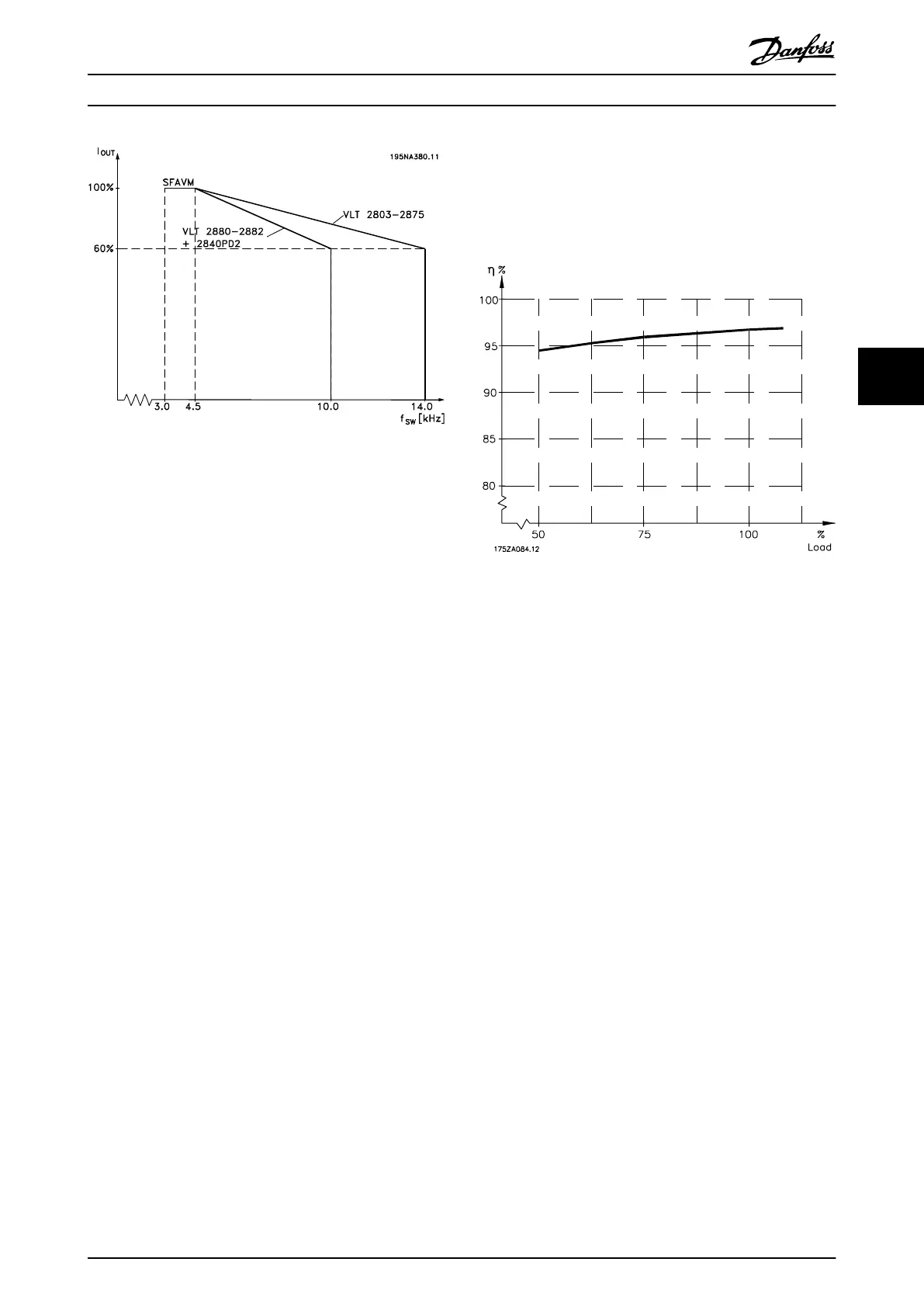

Illustration 5.5 Efficiency vs. Load

Efficiency of frequency converters (ŋ

INV

)

The load on the frequency converter has little effect on its

efficiency. In general, the efficiency is the same at the

rated motor frequency f

M,N

, regardless of whether the

motor supplies 100% rated shaft torque or only 75%, e.g.

in case of part loads.

This also means that the efficiency of the frequency

converter does not change even if other U/f characteristics

are selected. However, the U/f characteristics influence the

efficiency of the motor.

The efficiency decreases a little when the switching

frequency is set to a value above 4.5 kHz (parameter 411

Switching frequency). The rate of efficiency is also slightly

reduced at a high mains voltage (480 V), or if the motor

cable is longer than 25 m.

Efficiency of the motor (ŋ

MOTOR

)

The efficiency of a motor connected to the frequency

converter depends on the sine shape of the current. In

general, the efficiency is just as good as in mains

operation. The efficiency of the motor depends on the

motor type.

In the range of 75-100% of the rated torque, the efficiency

of the motor is practically constant, both when it is

controlled by the frequency converter and when it runs

directly on mains.

In general, the switching frequency does not affect the

efficiency of small motors.

All about VLT 2800

Design Guide

MG27E402 Danfoss A/S © Rev. May/2014 All rights reserved. 131

5 5

Loading...

Loading...