Preset ref.,

msb

Preset ref.,

lsb

Selection of

set-up

Output frequency

[Hz]

0 0 0 2.5

0 1 0 5

1 0 0 10

1 1 0 17.5

0 0 1 20

0 1 1 25

1 0 1 35

1 1 1 50

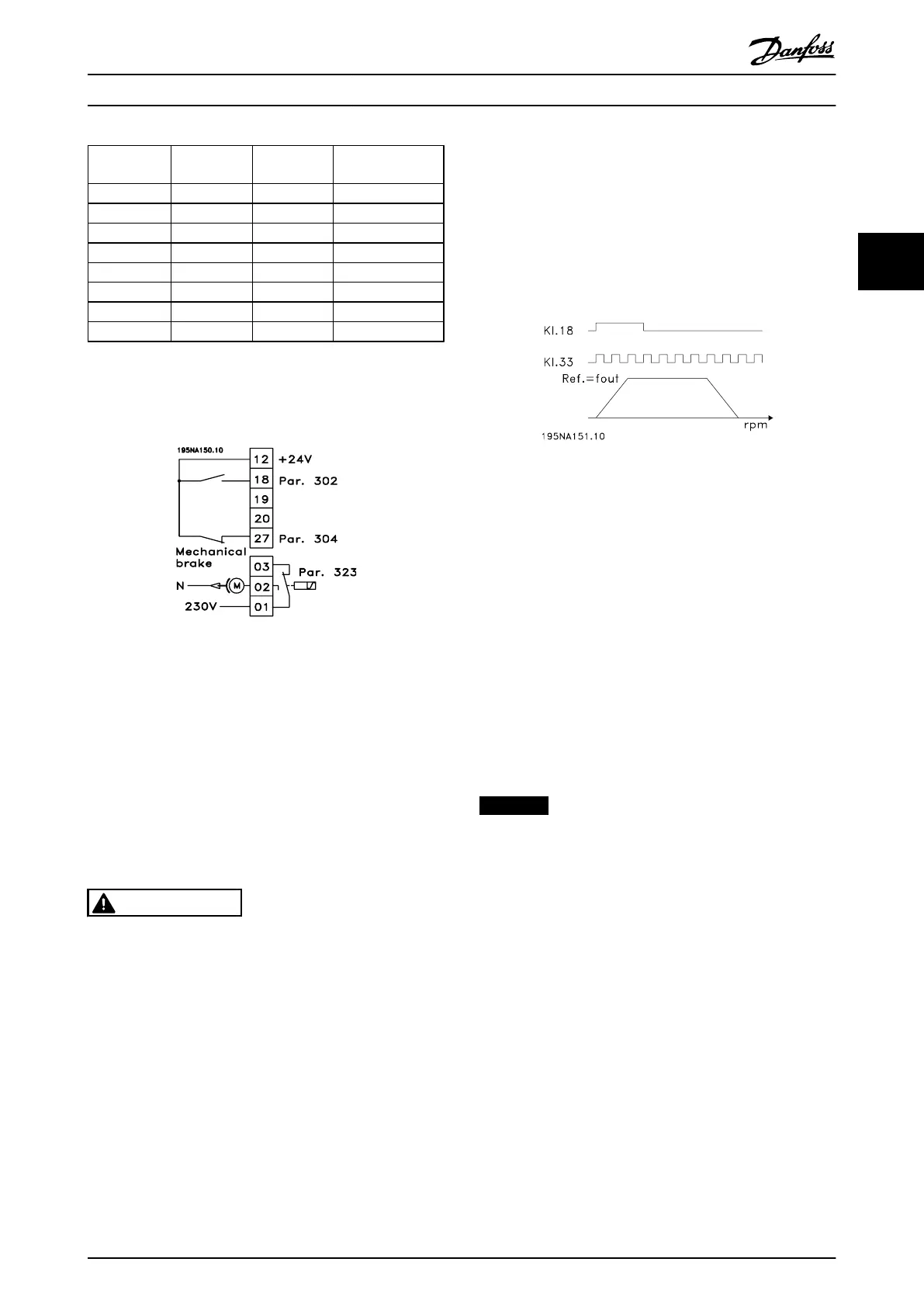

3.5.9 Connection of Mechanical Brake

Use of the relay for 230 V AC brake

Illustration 3.46 Connection of Mechanical Brake

•

Parameter 302 Digital input=[7] Start

•

Parameter 304 Digital input=[2] Coasting stop

inverted

•

Parameter 323 Relay output=[25] Mechanical brake

control

[25] Mechanical brake control='0' ⇒Brake is closed.

[25] Mechanical brake control='1' ⇒The brake is open.

See more detailed parameter settings in

chapter 3.4.13 Control of Mechanical Brake.

WARNING

Do not use the internal relay for DC brakes or brake

voltages > 250 V. There is a risk of equipment damage

and personal injury.

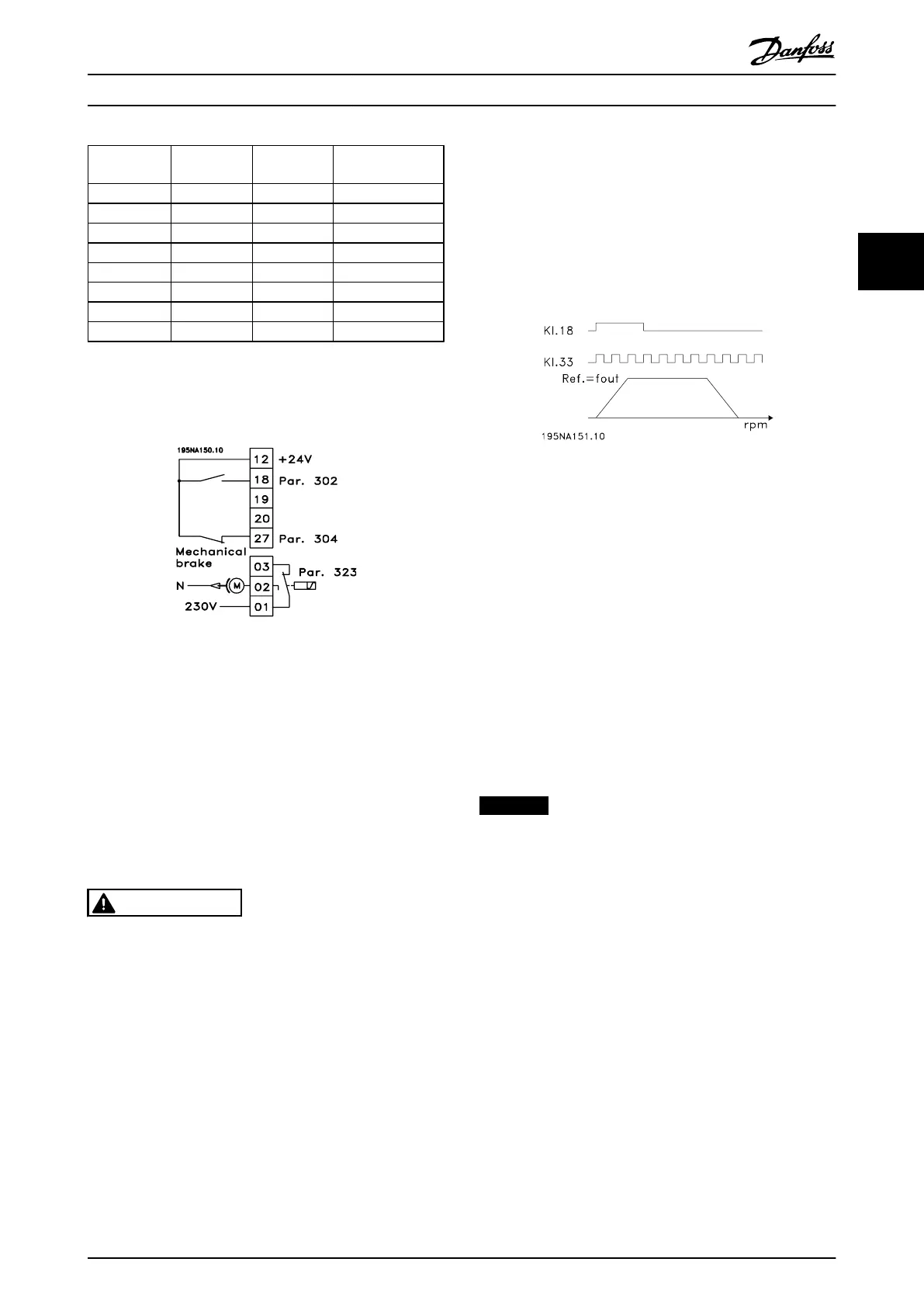

3.5.10 Counter Stop Through Terminal 33

The start signal (terminal 18) must be active, i.e. logical '1',

until the output frequency is equal to the reference. The

start signal (terminal 18 = logical '0') must then be

removed before the counter value in parameter 344

Counter value has managed to stop the frequency

converter.

Illustration 3.47 Counter Stop Through Terminal 33

•

Parameter 307 Digital input=[30] Pulse input

•

Parameter 343 Precise stop function=[1] Counter

stop with reset

•

Parameter 344 Counter value=100000

3.5.11

Use of Internal PID-Controller -

Closed Loop Process Control

1. Connect the frequency converter to mains and

motor cables as usual.

2. Connect transmitter (feedback signal) to +

terminal 12 and - terminal 60 (applies to 2-wire

transmitters 4-20 mA). (Connect transmitters with

0-10 V DC to + terminal 53 and - terminal 55).

NOTICE

Connect terminal 55 as - and terminal 60 as + for current

signal (0/4-20 mA) and terminal 53-55 for voltage signal

(0-10 V DC) if transmitters with separate voltage supply

are used.

3. Connect the start signal between terminal 12 and

18, 12-27 must be connected or set to no

function (Parameter 304 Digital input, term. 27=0).

4. Set all parameters in the Quick Menu and enter

the Main Menu (to enter the Main Menu: Press

[Quick Menu] and [+] simultaneously).

5. Set the following parameters:

•

Parameter 100 Configuration = [3] Process

controller closed loop

•

Parameter 101 Torque characteristic= [3] Variable

torque medium

•

If used with centrifugal pumps and fans.

•

Parameter 308 Terminal 53, analog input voltage=

[2] Feedback (for 0-10 V DC transmitters) or

Installation

Design Guide

MG27E402 Danfoss A/S © Rev. May/2014 All rights reserved. 59

3 3

Loading...

Loading...