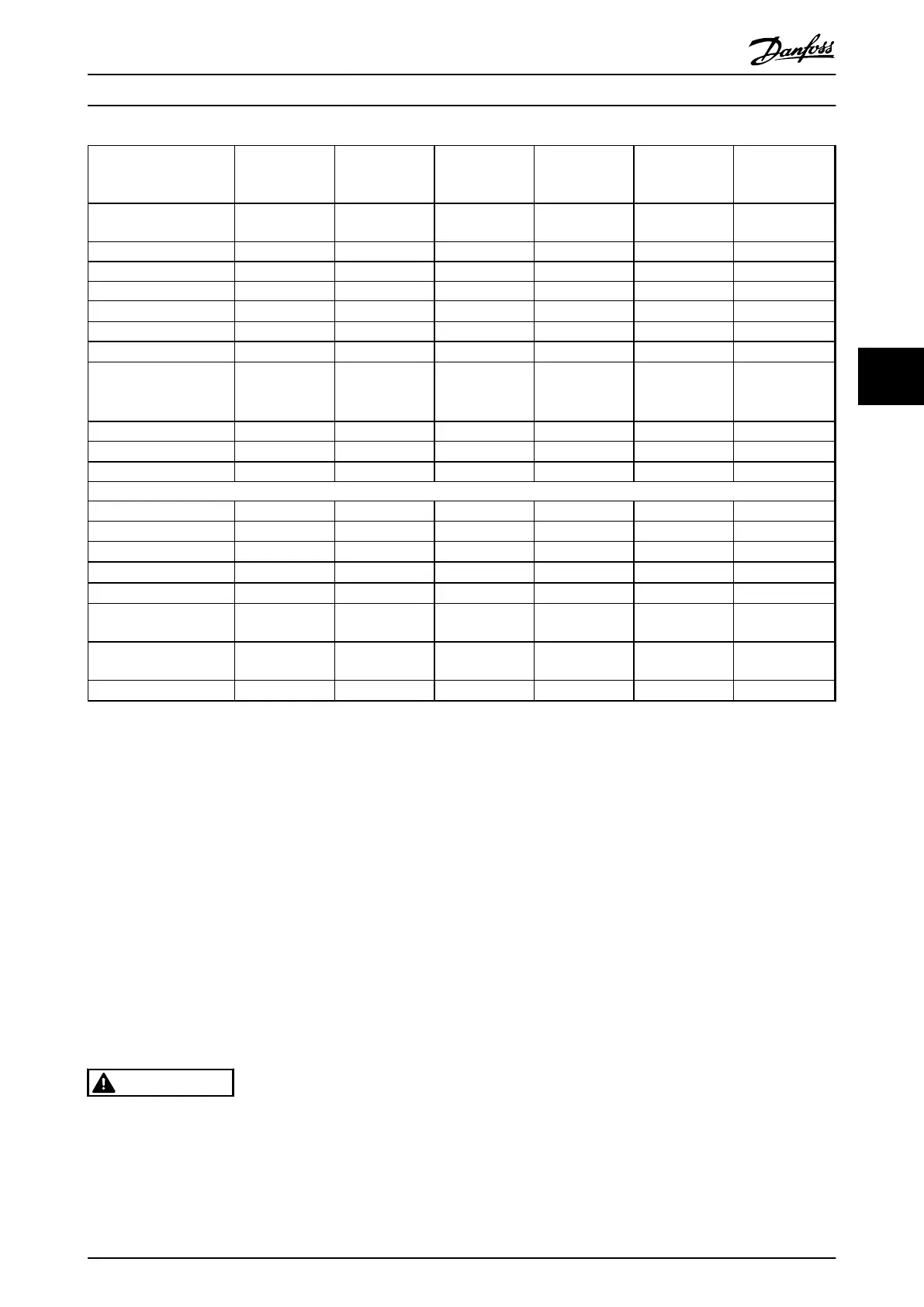

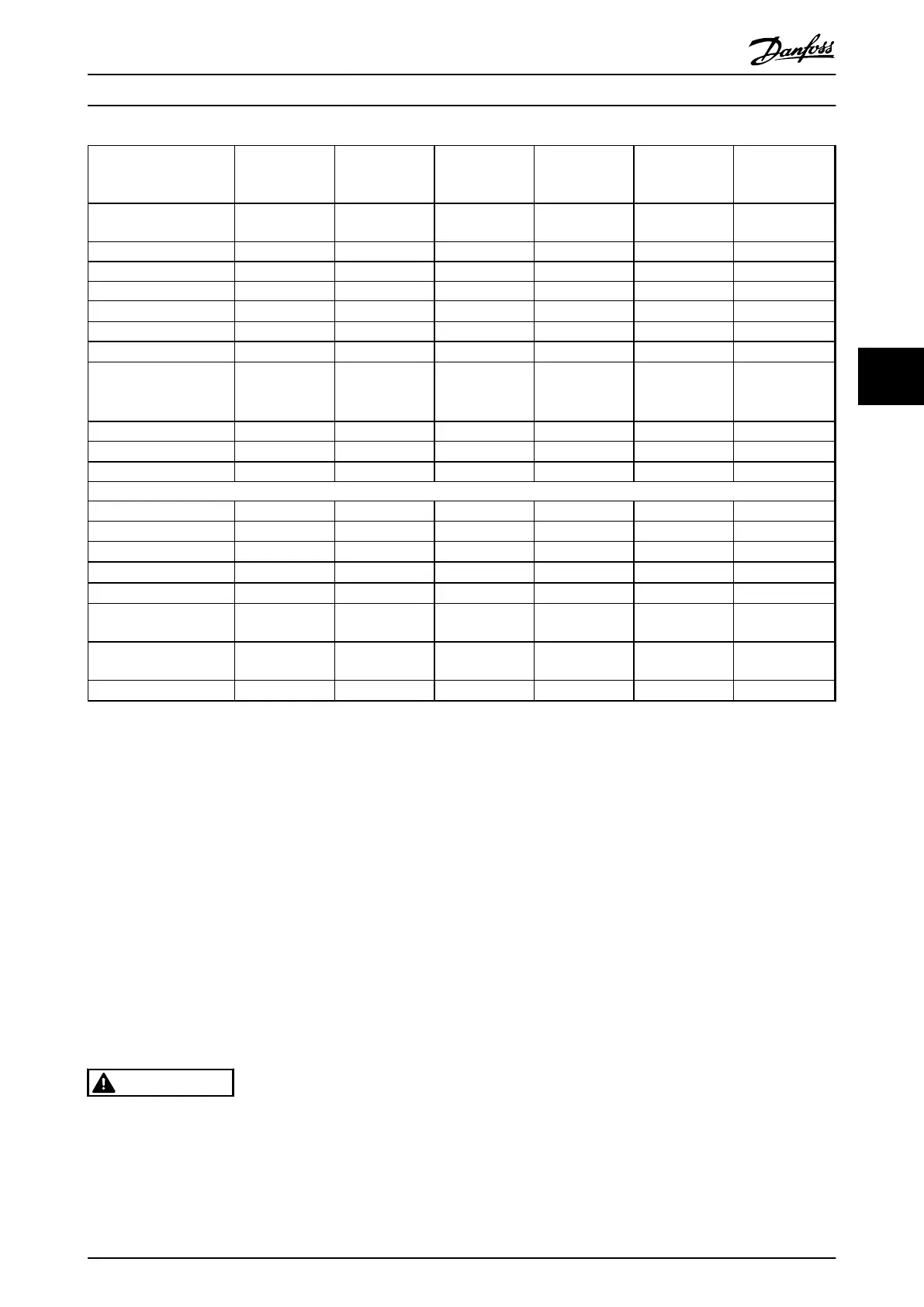

Basic standard Burst

61000-4-4

Surge

61000-4-5

ESD

61000-4-2

Radiated

61000-4-3

Mains

distortion

VDE 0160

RF CM

voltage

2)

61000-4-6

Acceptance

criterion

B B B A A

Port connection CM DM/CM Field DM CM

Line OK/OK OK

Motor OK

Control lines OK

-/OK

1)

OK

Relay OK -/OK OK

Profibus OK

-/OK

1)

OK

Signal interface

<3 m

OK

Enclosure OK OK

Standard bus OK

-/OK

1)

OK

Basic specifications

Line 2 kV/DCN 2 kV/4kV 10 V

rms

Motor 10 V

rms

Control lines 2 kV/CCC

2 kV/2 Ω

1)

10 Vrms

Relay 2 kV/CCC

2 kV/2 Ω

1)

10 V

rms

Profibus 2 kV/CCC

2 kV/2 Ω

1)

10 V

rms

Signal interface

<3 m

2 kV/CCC

Enclosure 8 kV AD

6 kV CD

10 V/m

Standard bus 2 kV/CCC

2 kV/2 Ω

1)

10 V

rms

Table 5.6 EMC Immunity Data

1) Injection on cable screen

DM: Differential mode

CM: Common mode

CCC: Capacitive clamp coupling (5 kHz)

DCN: Direct coupling network (5 kHz)

5.1.22 Harmonic Current Emission

All 3-phase 380-480 V units comply with EN 61000-3-2.

5.1.23 Aggressive Environments

As all other electronic equipment, a frequency converter

contains a number of mechanical and electronic

components, which to a varying extent are vulnerable to

environmental impact.

CAUTION

Do not install the frequency converter in environments

where liquids, particles or gases are in the air that would

impact and damage the electronics. Unless the necessary

measures are taken to protect the frequency converter,

there is a risk of stoppages, which reduce the service life

of the frequency converter.

Liquids can be carried through the air and condense in the

frequency converter. In addition, liquids may facilitate

galvanic corrosion of components and metal parts. Steam,

oil and brine may cause corrosion of components and

metal parts. In these areas, fit units in cabinets. As a

minimum, cabinets should be enclosure IP54.

Particles in the air, such as dust particles, may lead to

mechanical, electrical and thermal faults on the frequency

converter. Typical indicators that there are too many

particles in the air are dust particles around the frequency

converter fan. In very dusty areas, cabinet fitting of units is

recommended. As a minimum, cabinets should be

enclosure IP54.

Aggressive gases, such as sulphur, nitrogen and chlorine

compounds, together with high humidity and temperature,

facilitate possible chemical processes on the components

of the frequency converter. These chemical processes

All about VLT 2800 Design Guide

MG27E402 Danfoss A/S © Rev. May/2014 All rights reserved. 135

5 5

Loading...

Loading...