3.4.12 Tightening Torque for Power

Terminals

Tighten power and ground terminals with the following

torques:

VLT Terminals Torque [Nm]

2803-2875 Power mains brake 0.5-0.6

Ground 2-3

2880-2882,

2840 PD2

Power mains brake 1.2-1.5

Ground 2-3

3.4.13 Control of Mechanical Brake

In lifting/lowering applications, it’s necessary to control an

electromagnetic brake. The brake is controlled using a

relay output or digital output (terminal 46). The output

must be kept closed (voltage-free) for the period of time

during which the frequency converter is not able to

support the motor, for example due to the load being too

high. Select [25] Mechanical brake control in parameter 323

Relay output 1-3 or parameter 341 Digitial/Pulse output

terminal 46 for applications with an electromagnetic brake.

When the output frequency exceeds the brake cut-out

value set in parameter 138 Brake cut out value, the brake is

released if the motor current exceeds the preset value in

parameter 140 Current, minimum value. The brake is

engaged when the output frequency is less than the brake

engaging frequency, which is set in parameter 139 Brake

cut in frequency.

If the frequency converter is in alarm status or in an

overvoltage situation, the mechanical brake is cut in

immediately.

NOTICE

This application is only for lifting/lowering without a

counterbalance.

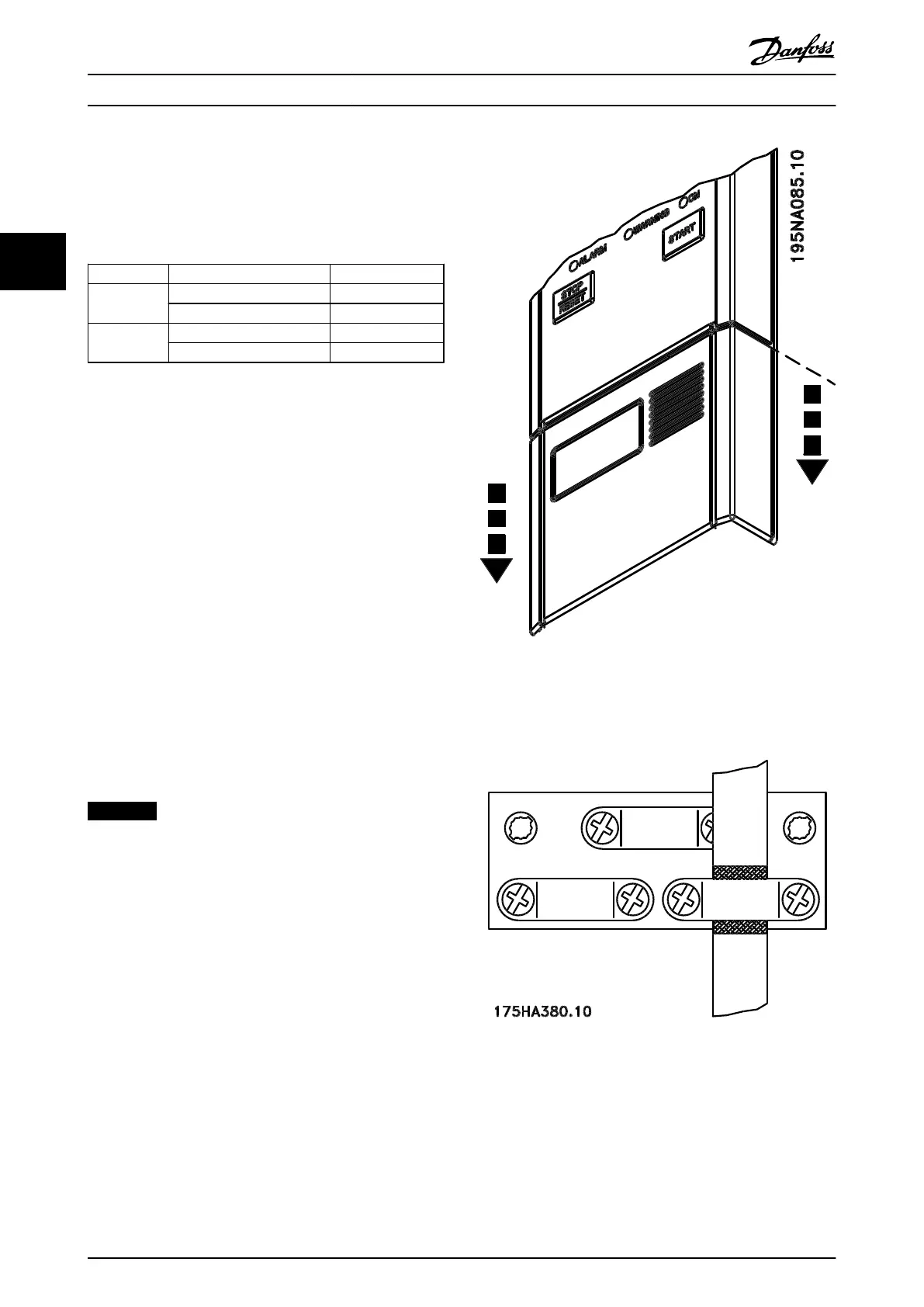

3.4.14 Access to Control Terminals

All terminals to the control cables are located underneath

the protective plate on the front of the frequency

converter. Remove the protective plate by pulling it

downwards, as shown in Illustration 3.31.

Illustration 3.31 Remove the Protective Cover

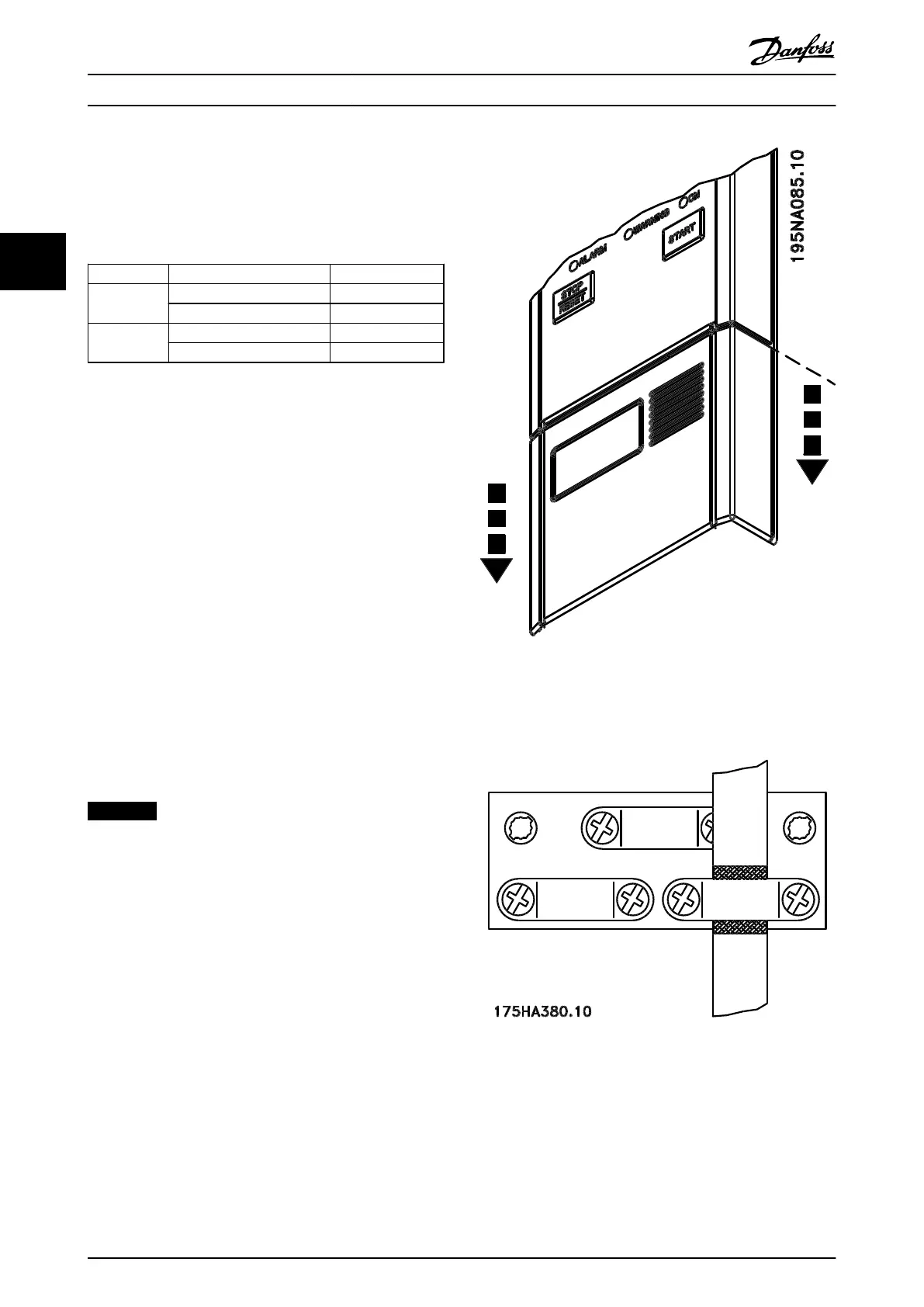

3.4.15

Control Cables

Illustration 3.32 Screen Control Cables

Use acreened/armoured control cables. Connect the screen

to the frequency converter chassis with a clamp. Normally,

the screen must also be connected to the chassis of the

controlling unit (use the instructions for the unit in

question). In connection with very long control cables and

analog signals, 50/60 Hz ground loops may occur because

Installation

Design Guide

52 Danfoss A/S © Rev. May/2014 All rights reserved. MG27E402

33

Loading...

Loading...