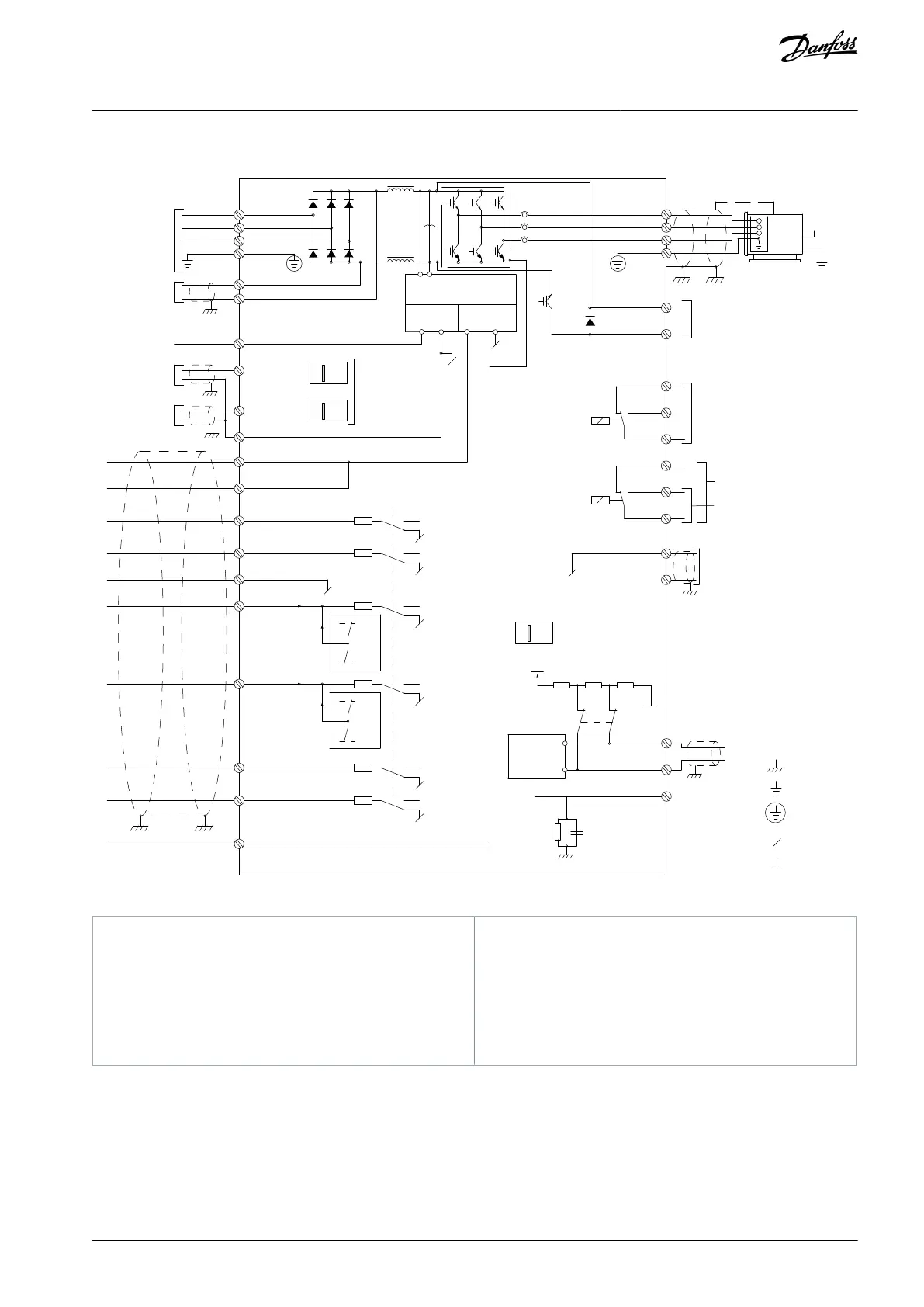

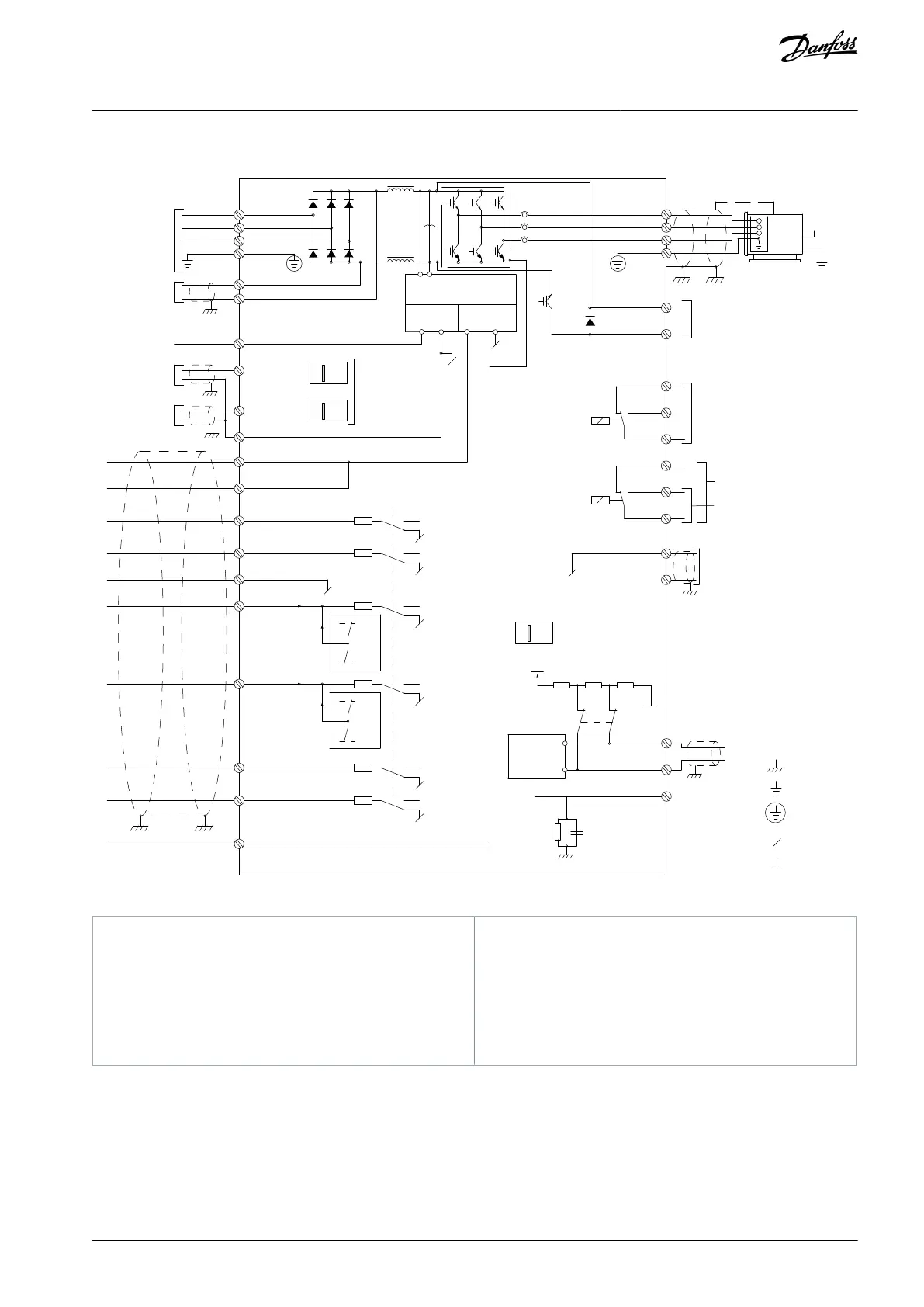

4.4 Wiring Schematic

––

Motor

Analog Output

ON=Terminated

OFF=Open

A IN)

37 (D IN)

1)

18 (D IN)

+ - + -

(U) 96

(V) 97

(W) 98

(PE) 99

(P RS485) 68

(N RS485) 69

0 V

5V

S801

0/4–20 mA

RS-485

03

240 V AC, 2 A

24 V DC

02

01

05

04

06

24

V (NPN)

33 (D IN)

32 (D IN)

S202

ON=0/4–20 mA

95

P 5-00

21

ON

S801

(R+) 82

(R-) 81

: Chassis

240 V AC, 2 A

400 V AC, 2 A

: PE

50 (+10 V OUT)

55 (COM A IN)

12 (+24 V OUT)

13 (+24 V OUT)

20 (COM D IN)

Switch mode

power supply

Brake

resistor

Relay 1

Relay 2

(COM A OUT) 39

(A OUT) 42

: Ground

: Ground 1

: Ground 2

(COM RS485) 61

OFF=0/-10 V DC

to +10 V DC

Illustration 6: Basic Wiring Schematic

Terminal 37 (optional) is used for Safe Torque Off

(STO). For installation instructions, refer to the VLT

®

Safe Torque Off Operating Guide. For FC 301, termi-

nal 37 is only included in enclosure size A1. Relay 2

and terminal 29 have no function in FC 301.

Do not connect cable shield.

Read more in EMC-Compliant Installation.

AQ267037727118en-000101 / 130R0300 | 17Danfoss A/S © 2021.01

Electrical Installation

VLT® AutomationDrive FC 301/FC 302

Operating Guide

Loading...

Loading...