1

High overload=150% or 160% torque for a duration of 60 s. Normal overload=110% torque for a duration of 60 s.

2

Applies for dimensioning of drive cooling. If the switching frequency is higher than the default setting, the power losses may increase. LCP and

typical control card power consumptions are included. For power loss data according to EN 50598-2, refer to Danfoss

MyDrive® ecoSmart website.

3

Efficiency measured at nominal current. For energy efficiency class, see

8.4 Ambient Conditions. For part load losses, see Danfoss MyDrive® ecoS-

mart website.

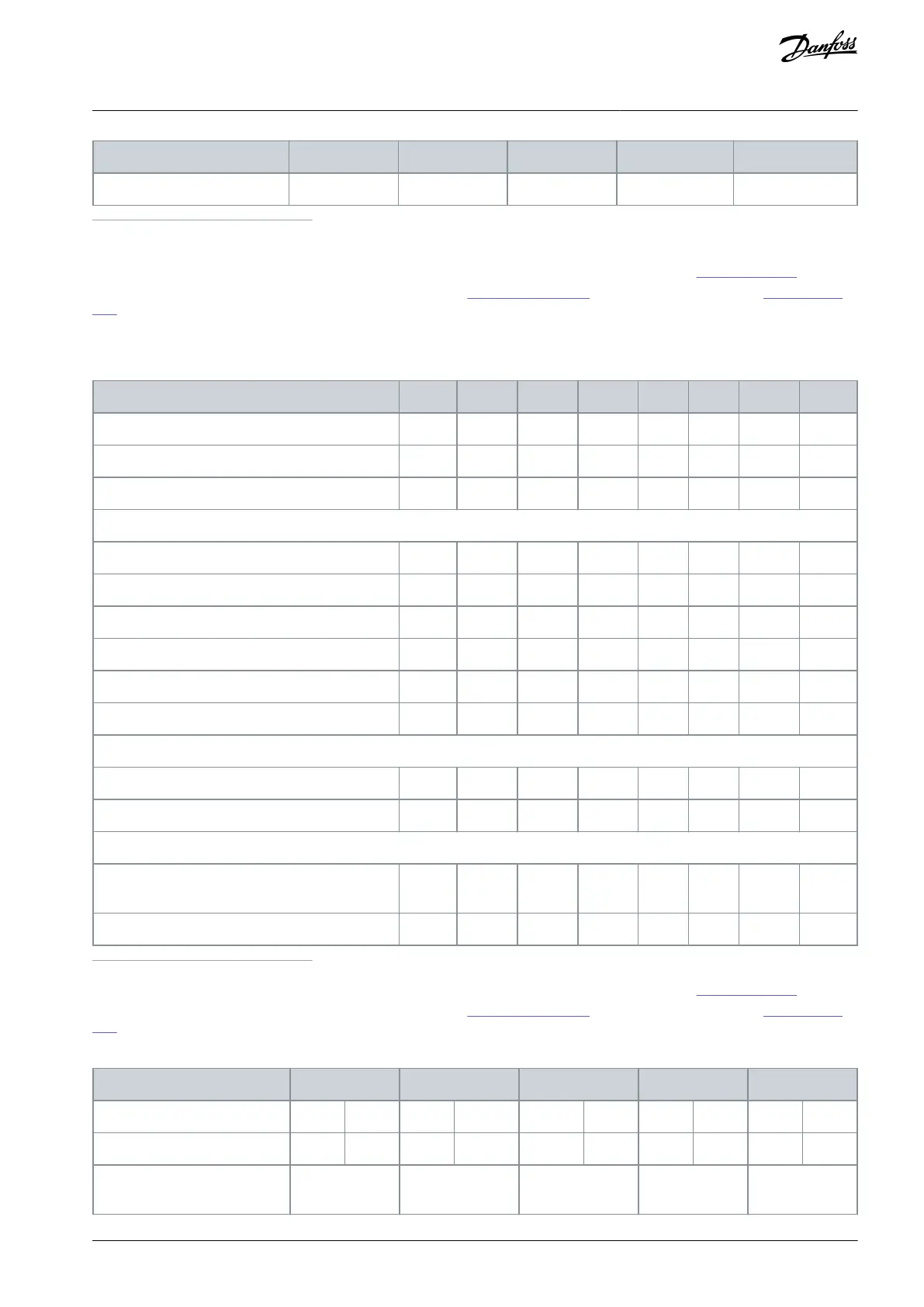

8.1.3 Mains Supply 525–600 V (FC 302 only)

Table 35: Mains Supply 525–600 V (FC 302 only), PK75–P7K5

Typical shaft output [kW/(hp)]

Enclosure protection rating IP20, IP21

Enclosure protection rating IP55

Continuous (525–550 V) [A]

Intermittent (525–550 V) [A]

Continuous (551–600 V) [A]

Intermittent (551–600 V) [A]

Continuous kVA (525 V) [kVA]

Continuous kVA (57 V) [kVA]

Continuous (525–600 V) [A]

Intermittent (525–600 V) [A]

Additional specifications

Estimated power loss at rated maximum load [W]

(1)

1

Applies for dimensioning of drive cooling. If the switching frequency is higher than the default setting, the power losses may increase. LCP and

typical control card power consumptions are included. For power loss data according to EN 50598-2, refer to Danfoss

MyDrive® ecoSmart website.

2

Efficiency measured at nominal current. For energy efficiency class, see 8.4 Ambient Conditions. For part load losses, see Danfoss MyDrive® ecoS-

mart website.

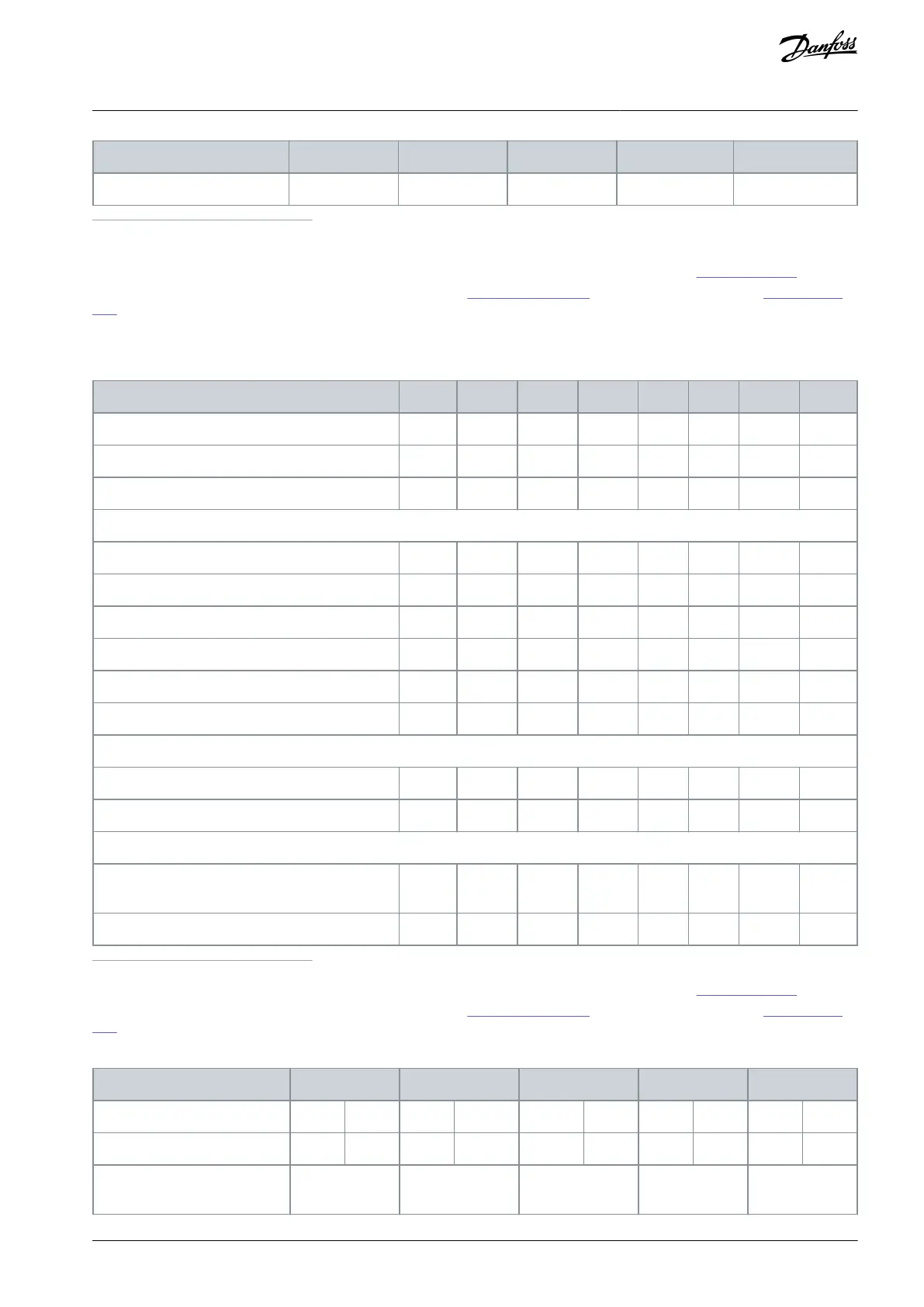

Table 36: Mains Supply 525–600 V (FC 302 only), P11K–P30K

Typical shaft output [kW/(hp)]

Enclosure protection rating

IP20

AQ267037727118en-000101 / 130R0300 | 65Danfoss A/S © 2021.01

Specifications

VLT® AutomationDrive FC 301/FC 302

Operating Guide

Loading...

Loading...