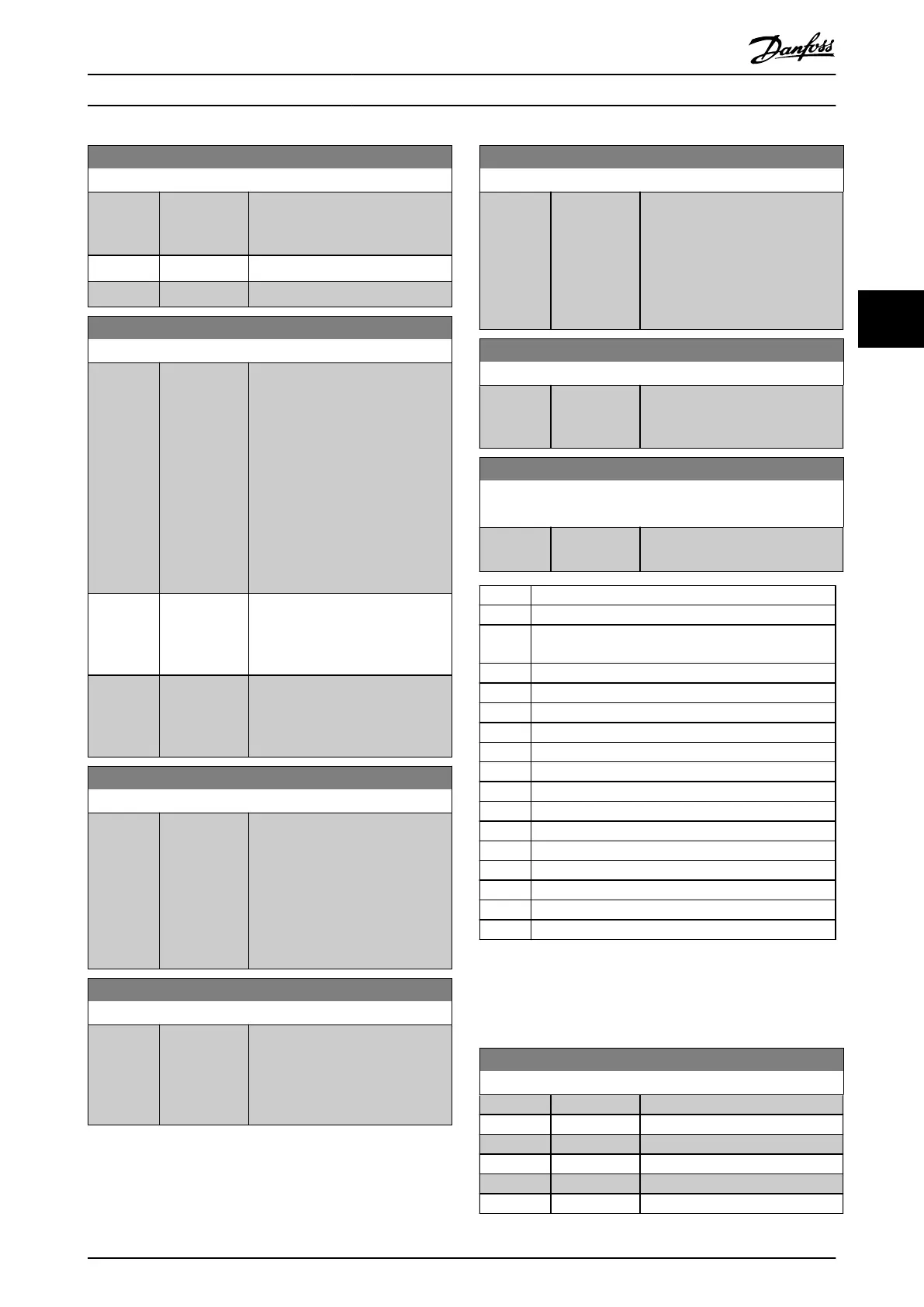

9-27 Parameter Edit

Option: Function:

Parameters can be edited via

PROFIBUS, the standard RS485

interface, or the LCP.

[0] Disabled Disable editing via PROFIBUS.

[1] * Enabled Enable editing via PROFIBUS.

9-28 Process Control

Option: Function:

Process control (setting of control

word, speed reference, and process

data) is possible via either

PROFINET or standard eldbus, but

not both simultaneously. Local

control is always possible via the

LCP. Control via process control is

possible via either terminals or

eldbus depending on the settings

in parameter 8-50 Coasting Select to

parameter 8-58 Prodrive OFF3

Select.

[0] Disable Disable process control via

PROFINET and enable process

control via standard eldbus or

PROFINET IO supervisor.

[1] * Enable cyclic

master

Enable process control via IO

controller and disable process

control via standard eldbus or

PROFINET IO supervisor.

9-44 Fault Message Counter

Range: Function:

0* [0 - 65535 ] This parameter shows the number

of error events stored in

parameter 9-45 Fault Code and

parameter 9-47 Fault Number. The

maximum buer capacity is eight

error events. The buer and counter

are set to 0 upon reset or power-

up.

9-45 Fault Code

Range: Function:

0* [0 - 0 ] This buer contains the alarm word

for all alarms and warnings that

have occurred since last reset or

power-up. The maximum buer

capacity is 8 error events.

9-47 Fault Number

Range: Function:

0* [0 - 0 ] This buer contains the alarm

number (for example, 2 for live zero

error, 4 for mains phase loss) for all

alarms and warnings that have

occurred since last reset or power-

up. The maximum buer capacity is

8 error events.

9-52 Fault Situation Counter

Range: Function:

0* [0 - 1000 ] This parameter shows the number

of error events that have occurred

since last reset or power-up.

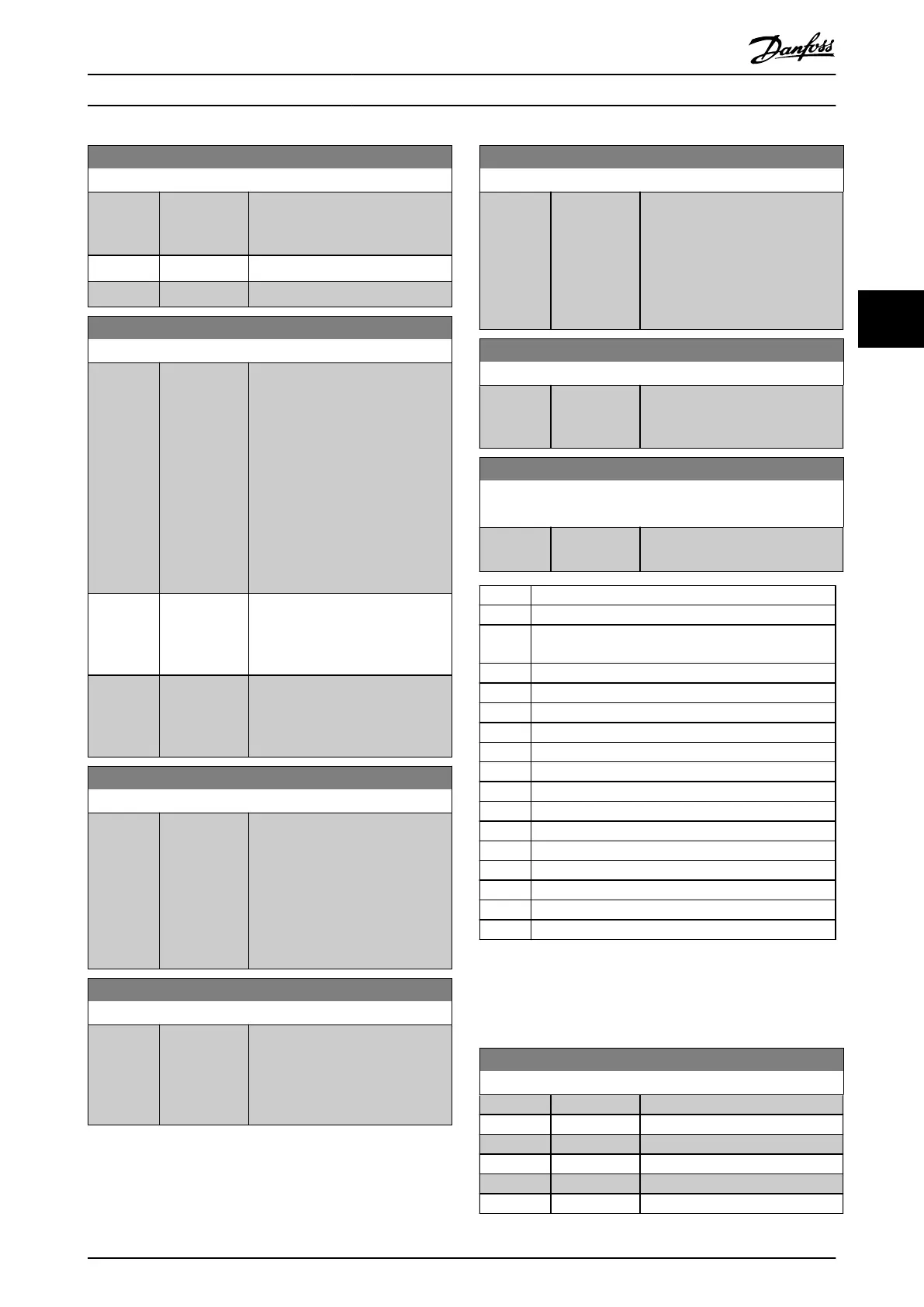

9-53 Probus Warning Word

Read only

Range: Function:

0* [0 - 65535 ] This parameter shows PROFINET

communication warnings.

Bit Condition when bit is active

0 Connection with IO controller is not OK.

1

Reserved for status of connection with second IO

controller.

2 Not used.

3 Clear data command received.

4 Actual value is not updated.

5 No link on both ports.

6 Not used.

7 Initializing of PROFINET is not OK.

8 Frequency converter is tripped.

9 Internal CAN error.

10 Wrong conguration data from IO controller.

11 Not used.

12 Internal error occurred.

13 Not congured.

14 Timeout active.

15 Warning 34 active.

Table 4.17 PROFINET Communication Warnings

This parameter shows the actual PROFIBUS baud rate. The

PROFIBUS master automatically sets the baud rate.

9-63 Actual Baud Rate

Option: Function:

[0] 9,6 kbit/s

[1] 19,2 kbit/s

[2] 93,75 kbit/s

[3] 187,5 kbit/s

[4] 500 kbit/s

[6] 1500 kbit/s

Parameter Descriptions Programming Guide

MG06J202 Danfoss A/S © 03/2019 All rights reserved. 109

4 4

Loading...

Loading...